Advancements in Automatic Cartoning Technology

Smart Integration and Industry 4.0

The landscape of automatic cartoning machines has been dramatically transformed by the integration of smart technologies and Industry 4.0 principles. Modern cartoning systems now boast advanced sensors, real-time monitoring capabilities, and predictive maintenance algorithms. These innovations allow for seamless connectivity with other production line equipment, facilitating a more synchronized and efficient packaging process. The implementation of machine learning algorithms enables these systems to adapt to varying product specifications and carton sizes with minimal human intervention, significantly reducing setup times and enhancing overall productivity.

Enhanced Flexibility and Customization

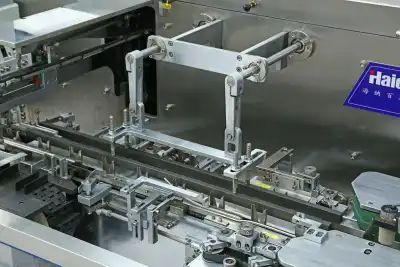

Today's automatic cartoning machines are engineered with an emphasis on flexibility and customization. Manufacturers have developed modular designs that allow for easy reconfiguration to accommodate different product types and packaging requirements. Quick-change tooling and servo-driven components enable rapid changeovers, minimizing downtime and maximizing production efficiency. This adaptability is particularly valuable in industries with diverse product lines or frequent packaging updates, such as pharmaceuticals and cosmetics.

Sustainability-Driven Design

In response to growing environmental concerns, innovative engineering in cartoning machines now incorporates sustainability-driven design principles. These include energy-efficient motors, optimized motion control to reduce power consumption, and the ability to handle eco-friendly packaging materials. Some advanced models even feature waste reduction mechanisms that minimize material scrap during the cartoning process, contributing to a more sustainable packaging operation.

Key Features of State-of-the-Art Cartoning Equipment

High-Speed Performance and Precision

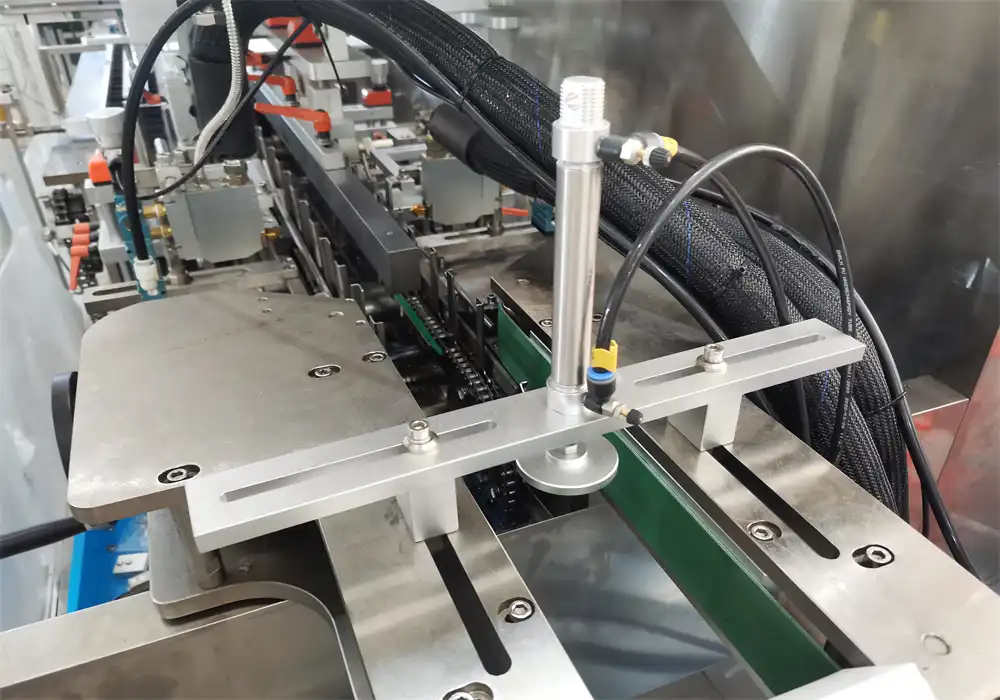

Modern automatic cartoning machines are marvels of speed and precision. Utilizing high-performance servo motors and sophisticated control systems, these machines can achieve remarkable throughput rates while maintaining exceptional accuracy. Advanced vision systems and quality control mechanisms ensure that each carton is formed, filled, and sealed to exacting standards, minimizing defects and ensuring product integrity. This combination of speed and precision allows manufacturers to meet demanding production schedules without compromising on quality.

User-Friendly Interfaces and Remote Monitoring

The latest cartoning equipment features intuitive human-machine interfaces (HMIs) that simplify operation and troubleshooting. These user-friendly touchscreen displays provide operators with real-time performance data, diagnostics, and easy access to machine settings. Furthermore, remote monitoring capabilities allow technicians to perform diagnostics and provide support from off-site locations, reducing downtime and maintenance costs. This level of accessibility and control empowers operators to optimize automatic cartoning machine performance and quickly address any issues that may arise.

Compact Footprint and Ergonomic Design

Innovative engineering has led to the development of cartoning machines with smaller footprints without sacrificing functionality. These space-efficient designs are particularly beneficial for facilities with limited floor space. Additionally, ergonomic considerations have been integrated into modern cartoning equipment, making tasks such as loading carton blanks and accessing maintenance points easier and safer for operators. The thoughtful layout of components not only enhances operator comfort but also contributes to improved overall efficiency and reduced fatigue-related errors.

Impact on Various Industries and Future Trends

Revolutionizing Pharmaceutical Packaging

The pharmaceutical industry has been particularly impacted by advancements in automatic cartoning technology. These machines now incorporate features specifically designed to meet the stringent requirements of drug packaging, including serialization capabilities for track-and-trace compliance, tamper-evident sealing mechanisms, and the ability to handle delicate products with extreme care. The precision and reliability of modern cartoning equipment play a crucial role in ensuring the safety and integrity of pharmaceutical products throughout the supply chain.

Enhancing Food and Beverage Packaging Efficiency

In the food and beverage sector, innovative cartoning machines have significantly improved packaging efficiency and hygiene standards. Advanced sanitary designs, including stainless steel construction and tool-less cleaning features, facilitate compliance with stringent food safety regulations. The ability to handle a wide range of product formats, from single-serve portions to family-size packages, with quick changeovers has made these machines indispensable in the fast-paced food industry. Moreover, the integration of modified atmosphere packaging (MAP) technology in some cartoning systems helps extend product shelf life and maintain freshness.

Future Trends: AI and Robotics Integration

Looking ahead, the future of automatic cartoning machines lies in the further integration of artificial intelligence and advanced robotics. Machine learning algorithms are expected to enhance predictive maintenance capabilities, potentially eliminating unplanned downtime. Collaborative robots (cobots) may be incorporated into cartoning lines to handle more complex tasks or to provide greater flexibility in product handling. As sustainability continues to be a priority, we can anticipate the development of cartoning machines specifically designed to work with new, eco-friendly packaging materials, further reducing the environmental impact of packaging operations.

Conclusion

The innovative engineering and design of automatic cartoning machines have ushered in a new era of packaging efficiency and precision. These advanced systems have become cornerstone technologies in various industries, offering unparalleled speed, accuracy, and adaptability. As we look to the future, the continued evolution of cartoning technology promises even greater levels of automation, sustainability, and integration with smart manufacturing principles. For businesses seeking to optimize their packaging operations, investing in state-of-the-art cartoning equipment is not just a choice but a strategic necessity in today's competitive market landscape.

Contact Us

To explore how our cutting-edge automatic cartoning machines can revolutionize your packaging process, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Let us help you take your packaging efficiency to the next level with our innovative solutions.