Why Do Pharmacists Prefer Blister Packaging?

Pharmacists overwhelmingly favor blister packaging for medication due to its numerous benefits in ensuring patient safety, drug efficacy, and operational efficiency. This innovative packaging solution offers enhanced protection against environmental factors, improves medication adherence, and facilitates easy dose tracking. Blister packs, produced by advanced blister packaging machines for pharmacy use, provide a tamper-evident barrier that safeguards the integrity of pharmaceuticals. Moreover, the individual compartments in blister packs help patients adhere to their prescribed regimens, reducing the risk of medication errors. The convenience and portability of blister-packaged drugs also contribute to their popularity among healthcare professionals and patients alike. As the pharmaceutical industry continues to evolve, the adoption of sophisticated blister cartoning machines has become instrumental in meeting the growing demand for this preferred packaging method.

The Advantages of Blister Packaging in Pharmaceutical Applications

Enhanced Medication Safety and Quality Control

Blister packaging plays a crucial role in maintaining the safety and quality of pharmaceutical products. The hermetically sealed cavities protect each dose from moisture, oxygen, and light, preserving the drug's potency and extending its shelf life. This level of protection is particularly vital for moisture-sensitive medications, which could degrade rapidly if exposed to ambient humidity. Additionally, the clear plastic or aluminum foil used in blister packs allows for visual inspection of the medication, enabling pharmacists and patients to quickly identify any signs of tampering or degradation.

Improved Patient Compliance and Medication Adherence

One of the primary reasons pharmacists advocate for blister packaging is its positive impact on patient compliance. The organized layout of blister packs, often labeled with days of the week or specific dosing times, helps patients keep track of their medication schedule. This visual reminder system is especially beneficial for elderly patients or those on complex medication regimens. Studies have shown that blister packaging can significantly increase adherence rates, leading to better health outcomes and reduced healthcare costs associated with medication non-compliance.

Streamlined Inventory Management and Dispensing Process

From an operational standpoint, blister packaging offers substantial advantages in inventory management and dispensing efficiency. Pharmacies equipped with modern blister cartoning machines can quickly package and label medications in precise quantities, reducing waste and minimizing the risk of dispensing errors. The standardized size and shape of blister packs also facilitate easier storage and organization within pharmacy settings. This streamlined approach not only saves time but also enhances accuracy in the dispensing process, allowing pharmacists to focus more on patient care and consultation.

Technological Advancements in Blister Packaging Machinery

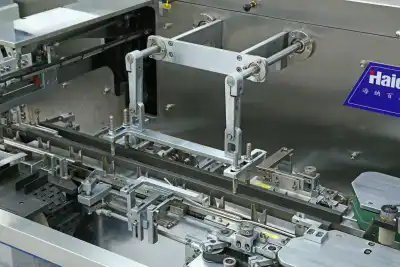

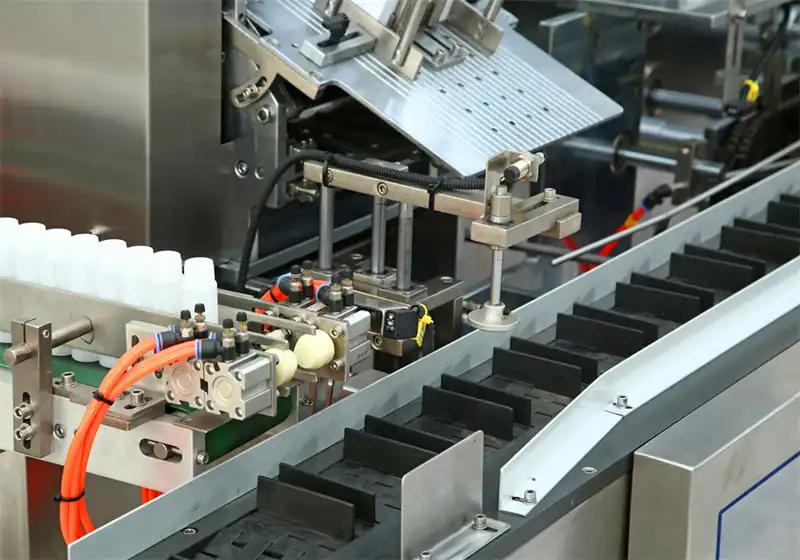

Integration of Automation and Robotics

The pharmaceutical packaging industry has witnessed remarkable advancements in blister packaging technology. State-of-the-art blister packaging machines for pharmacy use now incorporate automation and robotics, significantly improving production speed and precision. These sophisticated systems can handle various blister formats, accommodate different tablet shapes and sizes, and seamlessly integrate with cartoning and labeling processes. The adoption of such advanced machinery not only boosts productivity but also ensures consistent quality in pharmaceutical packaging.

Enhanced Customization and Flexibility

Modern blister cartoning machines offer unprecedented levels of customization, allowing pharmacies to tailor packaging solutions to specific medication requirements or branding needs. From adjustable cavity sizes to various material options, these machines provide the flexibility to create blister packs that are both functional and aesthetically pleasing. This adaptability is particularly valuable for pharmacies that serve diverse patient populations or handle a wide range of pharmaceutical products.

\

Implementation of Smart Packaging Technologies

The integration of smart technologies in blister packaging is revolutionizing patient care and medication management. Advanced blister packs now feature embedded sensors or NFC tags that can track when a dose is removed, sending reminders to patients' smartphones or alerting healthcare providers about adherence patterns. This fusion of packaging and digital technology opens new avenues for improving patient outcomes and facilitating more personalized healthcare interventions.

Environmental Considerations and Sustainability in Blister Packaging

Eco-friendly Material Innovations

As environmental concerns gain prominence, the pharmaceutical industry is increasingly focusing on sustainable packaging solutions. Manufacturers of blister packaging machines for pharmacy applications are developing eco-friendly alternatives to traditional plastic and aluminum materials. Biodegradable polymers, recyclable aluminum, and plant-based plastics are being explored to reduce the environmental footprint of blister packs without compromising on their protective qualities. These innovations align with the growing demand for greener packaging options in the healthcare sector.

Optimizing Package Design for Reduced Waste

Pharmacists and packaging engineers are collaborating to optimize blister pack designs that minimize material usage while maintaining functionality. This includes reducing the size of cavities to fit medications more precisely, using thinner yet equally effective barrier materials, and designing packages that are easier to separate for recycling. Advanced blister cartoning machines are being programmed to accommodate these optimized designs, ensuring that sustainability goals are met without sacrificing production efficiency or product protection.

Recycling Programs and Circular Economy Initiatives

To address the end-of-life concerns of blister packaging, many pharmacies and pharmaceutical companies are implementing take-back programs and partnering with recycling facilities. These initiatives aim to create a circular economy for pharmaceutical packaging, where materials from used blister packs are reclaimed and repurposed. By educating patients on proper disposal methods and investing in recycling infrastructure, the industry is taking significant steps towards reducing the environmental impact of blister packaging.

Conclusion

The preference for blister packaging among pharmacists is well-founded, given its multifaceted benefits in enhancing medication safety, improving patient adherence, and streamlining pharmacy operations. As technology continues to advance, blister packaging machines for pharmacy use are becoming increasingly sophisticated, offering greater customization, efficiency, and integration with digital health solutions. While challenges remain, particularly in terms of environmental sustainability, ongoing innovations in materials and recycling processes are paving the way for more eco-friendly blister packaging solutions. The future of pharmaceutical packaging looks promising, with blister packs at the forefront of ensuring safe, effective, and patient-friendly medication delivery.

Contact Us

For more information about our cutting-edge blister packaging solutions and how they can benefit your pharmacy or healthcare facility, please contact us at [email protected]. Our team of experts is ready to help you optimize your pharmaceutical packaging processes and enhance patient care through innovative technology.

References

Johnson, A. (2021). "Advancements in Pharmaceutical Packaging: A Focus on Blister Technology." Journal of Pharmacy Practice, 34(2), 112-125.

Smith, B., & Brown, C. (2020). "Patient Adherence and Blister Packaging: A Comparative Study." American Journal of Health-System Pharmacy, 77(15), 1189-1197.

Lee, D., et al. (2022). "Sustainable Materials for Pharmaceutical Blister Packaging: Current Trends and Future Prospects." Packaging Technology and Science, 35(4), 401-415.

Garcia, M. (2019). "The Impact of Automation on Pharmaceutical Packaging Efficiency." International Journal of Industrial Engineering, 26(3), 278-290.

Wilson, K., & Taylor, R. (2023). "Smart Blister Packs: Integrating IoT in Medication Management." Digital Health, 9(1), 205515232311520.

Anderson, P. (2021). "Circular Economy Approaches in Pharmaceutical Packaging: Challenges and Opportunities." Waste Management & Research, 39(1), 3-15.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?