Understanding the Basics of Blister Packaging Machinery

The Fundamentals of Blister Packaging

Blister packaging is a widely used method in pharmaceutical and consumer goods industries, where a product is encased between a thermoformed plastic cavity and a backing material like aluminum foil or paperboard. This method offers a balance of protection, visibility, and tamper resistance. The packaging process begins by heating a plastic sheet, which is then molded into cavities using a forming station. Products are placed into these blisters, after which a sealing station applies heat and pressure to affix the backing material, securing each product within its own compartment.

Components of a Blister Packaging Machine

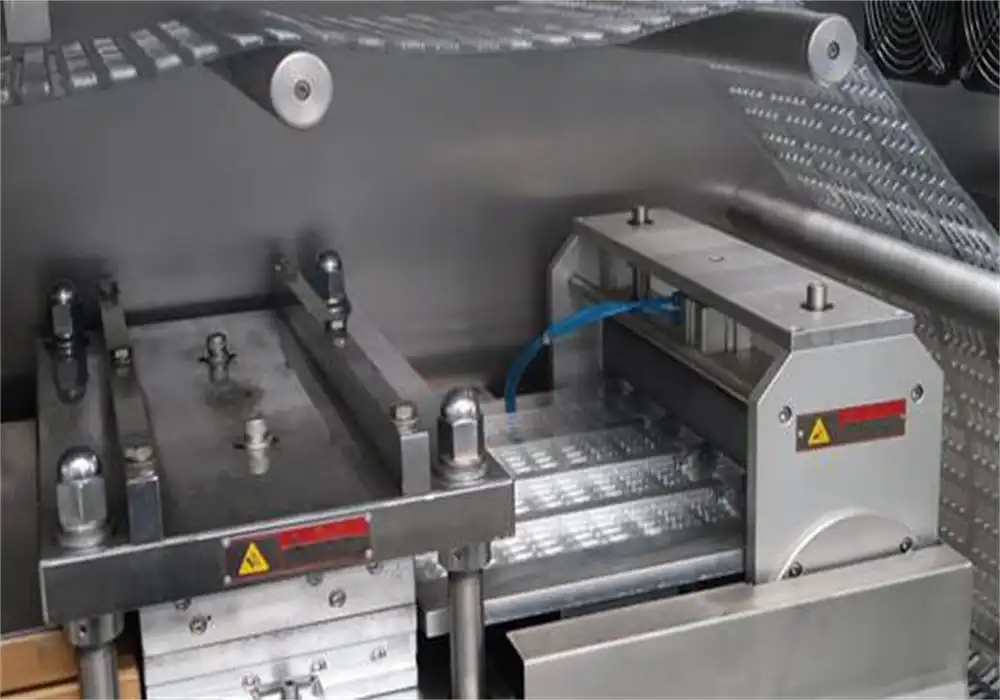

A blister packaging machine is composed of multiple coordinated systems, each serving a vital role in the packaging process. The feeding system transports products to the forming station, where the plastic sheet is shaped into blisters. The sealing station applies consistent heat and pressure to bond the blister with a foil or paperboard backing. After sealing, the cutting station trims the sheet into individual blister packs. All of these operations are monitored and controlled by an integrated control system that ensures precision, efficiency, and adaptability for different packaging requirements

.

Benefits of Using Blister Packaging Machines

Blister packaging machines deliver numerous benefits across industries. They protect products from environmental factors such as moisture, oxygen, and physical damage, ensuring extended shelf life and integrity. The clear plastic also offers excellent visibility, allowing consumers to inspect the product before purchase. The sealed design provides tamper evidence and unit-dose convenience, especially important in pharmaceutical use. Additionally, the machines, along with blister cartoning machine, support high-speed, automated production with customizable formats, enabling manufacturers to meet branding, regulatory, and efficiency goals while maintaining consistent packaging quality and traceability throughout the supply chain.

Types of Blister Packaging Machines for Various Industries

Manual Blister Packaging Machines

Manual blister packaging machines are ideal for small-scale operations or product testing. These machines require operators to perform most tasks manually, including loading products and feeding materials. While slower than automated options, manual machines offer flexibility and lower initial investment costs. They're well-suited for short production runs, custom projects, or businesses just starting with blister packaging.

Semi-Automatic Blister Packaging Machines

Semi-automatic blister packaging machines strike a balance between manual and fully automated systems. These machines automate some processes while still requiring operator involvement for others. For example, the forming and sealing stations may be automated, but product loading might be manual. Semi-automatic machines, often used alongside a blister cartoning machine, offer increased productivity over manual options while maintaining flexibility and requiring less capital investment than fully automated lines.

Fully Automatic Blister Packaging Machines

Fully automatic blister packaging machines represent the pinnacle of packaging efficiency. These high-speed systems automate the entire packaging process, from material feeding to final package discharge. Ideal for large-scale production, automatic machines can achieve outputs of hundreds of packages per minute. They often incorporate advanced features like vision inspection systems, integrated cartoning capabilities, and recipe management for quick changeovers between product runs.

Specialized Blister Packaging Solutions for Pharmaceuticals

Blister Packaging Machines for Pharmacy Applications

The pharmaceutical industry has unique requirements for packaging, including strict hygiene standards and regulatory compliance. Blister packaging machines for pharmacy applications are designed to meet these demands. They often feature cleanroom-compatible designs, materials suitable for medical use, and validation documentation to support Good Manufacturing Practice (GMP) compliance. These machines can handle various pharmaceutical formats, including tablets, capsules, ampoules, and pre-filled syringes.

Integrated Blister Cartoning Machines

Blister cartoning machines combine blister packaging and cartoning operations into a single, efficient system. These integrated solutions form blisters, seal products, and then automatically insert the blister packs into cartons. By streamlining the packaging process, blister cartoning machines reduce labor requirements, minimize product handling, and ensure consistent packaging quality. They're particularly valuable in pharmaceutical operations where maintaining product integrity throughout the packaging process is crucial.

Cold Forming Blister Machines for Sensitive Products

Some pharmaceutical products are sensitive to heat or moisture, making traditional thermoformed blister packaging unsuitable. Cold forming blister machines address this challenge by using aluminum foil instead of plastic for the blister cavity. The foil is mechanically formed into cavities without heat, preserving the integrity of heat-sensitive medications. While typically slower and more expensive than thermoforming, cold forming offers superior barrier properties and is often necessary for certain drug formulations.

Conclusion

Blister packaging machines play a crucial role in protecting and presenting products across various industries, with particular importance in the pharmaceutical sector. From manual tabletop units to high-speed automated lines, there's a blister packaging solution for every production need. Understanding the different types of blister packaging machines, including specialized pharmaceutical options like blister cartoning machines and cold forming systems, is essential for selecting the right equipment for your packaging requirements. By choosing the appropriate blister packaging technology, businesses can enhance product protection, improve operational efficiency, and meet regulatory standards.

Contact Us

To learn more about our range of blister packaging solutions, including blister cartoning machines and blister packaging machines for pharmacy applications, please contact us at [email protected]. Our team of experts at Zhejiang Haizhong Machinery Co., Ltd. is ready to help you find the perfect packaging solution for your needs.