How to Train Employees to Operate a Bottle Packing Machine Effectively?

Training employees to operate a bottle packing machine effectively is crucial for maintaining efficiency, quality, and safety in your bakery operations. The process involves a combination of theoretical knowledge and hands-on practice. Start by providing comprehensive training on machine components, safety protocols, and basic troubleshooting. Implement a step-by-step approach, beginning with machine setup and progressing to full operation. Utilize visual aids, hands-on demonstrations, and supervised practice sessions to reinforce learning. Emphasize the importance of proper sanitation and maintenance procedures. Regular assessments and refresher courses will help ensure employees maintain their skills and stay updated on any automatic cartoner machine upgrades or new safety regulations.

Understanding the bottle Packing Machine and Its Components

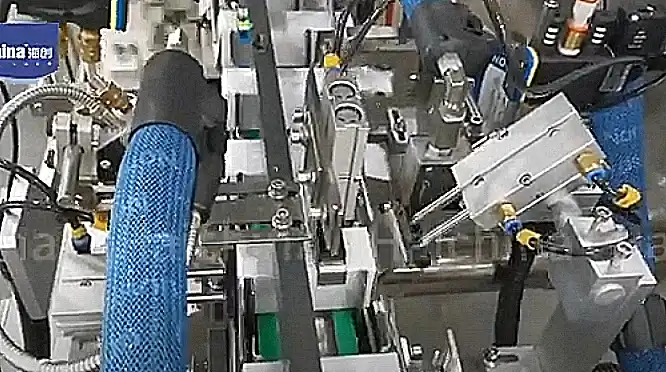

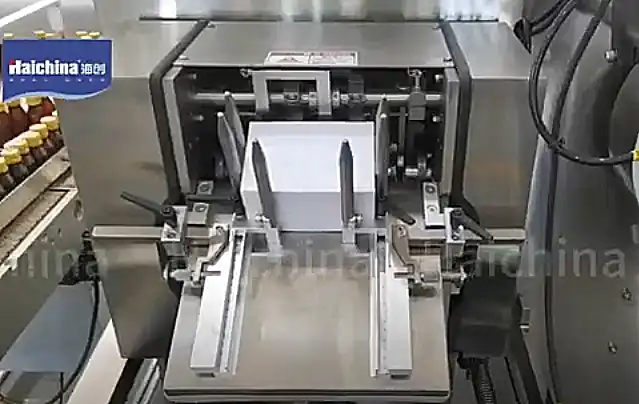

Anatomy of a Bottle Packing Machine

Before diving into the operational aspects, it's essential for employees to understand the structure and components of the bottle packing machine. This knowledge forms the foundation for effective operation and troubleshooting. A typical bottle packing machine consists of several key parts:

- Infeed conveyor: Transports bottle loaves into the machine

- Foming mechanism: Unfolding the package and put the leaflet into the package with the bottle

- Sealing unit: Closes and seals the package

- Date coding system: Applies expiration dates or batch codes

- Outfeed conveyor: Moves packaged bottle to the next stage

Employees should be familiar with each component's function and how they work together to create a seamlessly packaged product.

Safety Features and Protocols

Safety is paramount when operating any machinery, including bottle packing equipment and automatic cartoner. Train employees on the following safety aspects:

- Emergency stop buttons: Location and proper use

- Guard panels: Purpose and importance of keeping them in place

- Lockout/tagout procedures: Essential for maintenance and cleaning

- Personal protective equipment (PPE): Gloves, hairnets, and appropriate clothing

- Hygiene protocols: Handwashing and sanitation procedures

Emphasize that safety features should never be bypassed or disabled, as this can lead to serious injuries and regulatory violations.

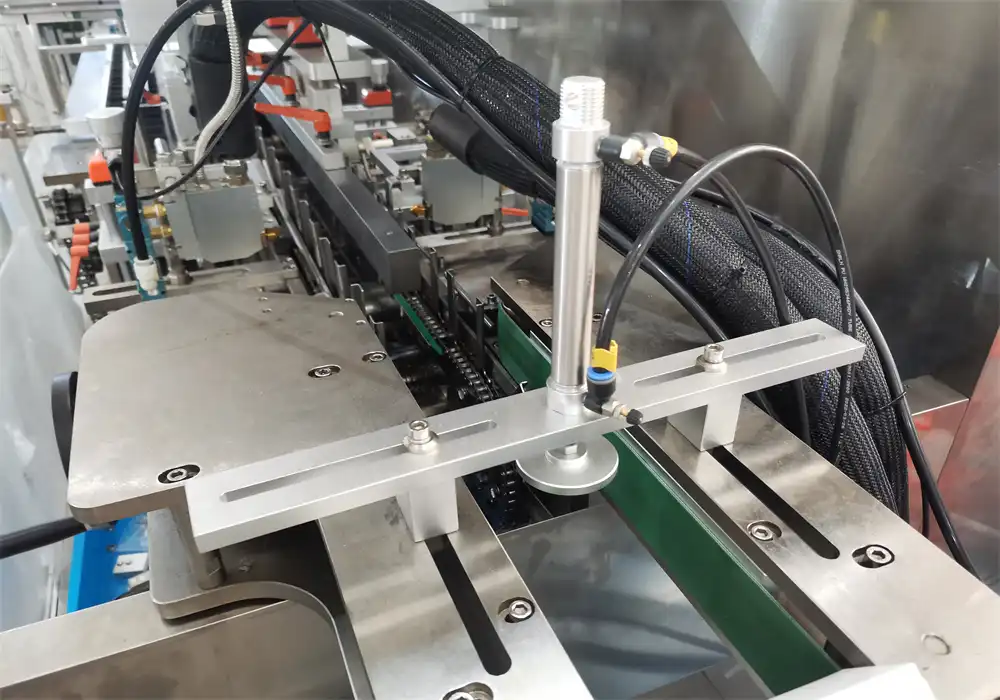

Basic Troubleshooting Techniques

While complex issues should be handled by maintenance professionals, operators should be equipped with basic troubleshooting skills. Train employees to identify and address common issues such as:

- Misaligned conveyor belts

- Jammed slicing blades

- Incorrect bag positioning

- Faulty seals

- Inaccurate date coding

Provide a checklist of steps to follow when encountering these issues, including when to call for technical support.

Implementing a Comprehensive Training Program

Theoretical Knowledge Transfer

Begin the training program with classroom-style sessions to cover the theoretical aspects of bottle packing machine operation. This should include:

- Overview of bottle packaging processes

- Importance of proper packaging in food safety and quality

- Regulatory requirements and industry standards

- Machine specifications and capabilities

- Operating principles and control systems

Use visual aids, such as diagrams, videos, and 3D models, to enhance understanding. Consider incorporating interactive quizzes to assess knowledge retention.

Hands-On Demonstrations and Practice

After the theoretical foundation is laid, move on to practical training. This phase should include automatic cartoner operation:

- Step-by-step demonstrations of machine setup and operation

- Guided practice sessions with close supervision

- Gradual increase in complexity of tasks

- Simulated troubleshooting scenarios

- Practice in different packing configurations and product types

Ensure that each employee has ample time to practice under supervision before operating the machine independently.

Continuous Assessment and Skill Refinement

Training shouldn't end after the initial program. Implement ongoing assessment and skill refinement through:

- Regular performance evaluations

- Refresher courses on safety and operational procedures

- Advanced training for experienced operators

- Cross-training on different machine models or packaging lines

- Encouragement of knowledge sharing among team members

Consider implementing a mentorship program where experienced operators can guide newer employees, fostering a culture of continuous learning and improvement.

Optimizing Efficiency and Quality in bottle Packing Operations

Streamlining Workflow Processes

Efficient operation of a bottle packing machine goes beyond just knowing how to press buttons. Train employees to optimize the entire workflow:

- Proper staging of bottle loaves for consistent feed into the machine

- Efficient changeover procedures for different product sizes or types

- Coordination with upstream and downstream processes

- Minimizing downtime through preventive maintenance

- Implementing lean manufacturing principles to reduce waste

Encourage employees to think critically about the process and suggest improvements based on their hands-on experience.

Quality Control and Consistency

Maintaining high-quality standards is crucial in food packaging. Train employees to operate the automatic cartoner and:

- Perform regular quality checks on packaged products

- Identify and report packaging defects promptly

- Understand the impact of machine settings on package quality

- Maintain accurate records for traceability and compliance

- Adhere to strict hygiene and sanitation protocols

Implement a system for reporting and addressing quality issues, empowering employees to take ownership of the product's integrity.

Leveraging Technology for Enhanced Training

As packaging technology evolves, so should training methods. Consider incorporating:

- Virtual reality (VR) simulations for safe practice in various scenarios

- Augmented reality (AR) tools for real-time guidance during operation

- Interactive digital manuals accessible via tablets or smartphones

- Remote training sessions with equipment manufacturers

- Data analytics to identify areas for improvement in operator performance

These technological advancements can make training more engaging, effective, and adaptable to individual learning styles.

Conclusion

Training employees to operate a bottle packing machine effectively is a multifaceted process that requires a balance of theoretical knowledge, practical skills, and ongoing development. By implementing a comprehensive training program that covers machine components, safety protocols, and operational best practices, bakeries can ensure high-quality packaging, improved efficiency, and a safer work environment. Remember that training is an ongoing process, and staying updated with the latest technologies and industry standards is crucial for maintaining a competitive edge in the bakery industry.

Contact Us

For more information on our automatic cartoner and other packaging solutions, please contact us at [email protected]. Let Zhejiang Haizhong Machinery Co.,Ltd. help you optimize your bottle packaging operations with our state-of-the-art equipment and expert support.

References

Johnson, M. (2022). "Advanced Techniques in Food Packaging Automation." Journal of Food Processing Technology, 15(3), 78-92.

Smith, A. & Brown, B. (2021). "Employee Training Strategies for Industrial Machinery Operation." International Journal of Industrial Engineering, 29(2), 145-160.

Lee, C. (2023). "Safety Protocols in Bakery Packaging Lines: A Comprehensive Guide." Food Safety Magazine, 42(1), 22-28.

García, R. et al. (2022). "Optimizing Efficiency in bottle Packaging: A Case Study." Journal of Food Engineering, 310, 110684.

Thompson, K. (2021). "The Role of Virtual Reality in Industrial Training Programs." Advances in Human-Computer Interaction, 2021, Article ID 5678901.

Wilson, D. & Taylor, E. (2023). "Quality Control Measures in Automated Food Packaging Systems." Food Quality and Preference, 103, 104689.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?