Understanding Blister Packaging: Types and Applications

Thermoformed vs. Cold-Formed Blister Packaging

Blister packaging comes in two primary types: thermoformed and cold-formed. Thermoformed blister packaging involves heating and molding plastic sheets into the desired shape, offering excellent visibility and customization options. This type is commonly used for consumer goods and electronics. Cold-formed blister packaging, on the other hand, uses aluminum foil or plastic films that are pressed into shape without heat. It provides superior barrier properties and is often preferred for sensitive pharmaceutical products.

Industry-Specific Applications

Different industries have unique requirements for blister packaging. In the pharmaceutical sector, blister packs are essential for maintaining drug integrity and ensuring proper dosage. The cosmetics industry utilizes blister packaging to showcase product aesthetics while protecting delicate items. Consumer electronics benefit from blister packaging's ability to prevent damage and deter theft. Understanding your industry's specific needs is crucial in selecting the right blister packaging solution and the appropriate blister packaging machine to meet those needs effectively.

Innovations in Blister Packaging Technology

Recent advancements in blister packaging technology have introduced eco-friendly materials, smart packaging features, and enhanced barrier properties. Biodegradable blister materials are gaining traction as businesses strive for sustainability. Smart blister packs with embedded sensors can track product usage and provide valuable data. High-barrier films offer extended shelf life for sensitive products. Staying informed about these innovations can help you choose a cutting-edge solution that sets your product apart in the market.

Key Factors in Selecting Blister Packaging Machines

Production Capacity and Scalability

When choosing a blister packaging machine, consider your current production needs and future growth projections. High-speed blister packaging machines can significantly boost output, but they may require a larger initial investment. Scalable machines offer the flexibility to increase production capacity as your business grows. Assess your long-term goals and select a machine that can accommodate your production volume without compromising on quality or efficiency.

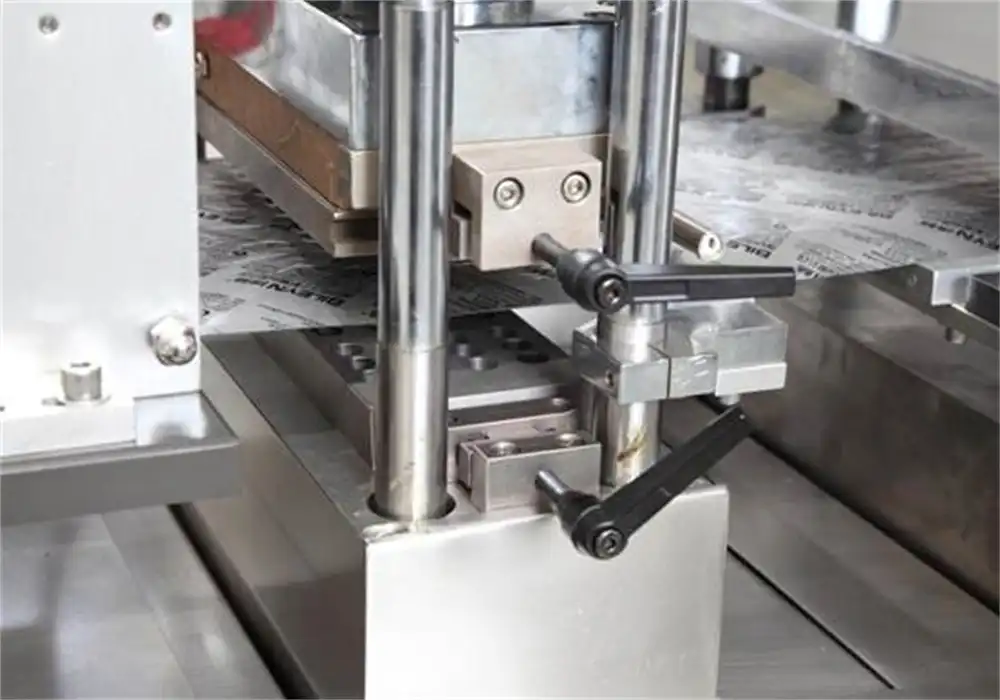

Versatility and Changeover Time

If your business handles diverse product lines, opt for a blister packaging machine that offers quick and easy changeovers. Look for machines with modular designs and tool-less changeover features. This versatility allows you to switch between different product sizes and shapes efficiently, minimizing downtime and maximizing productivity. Additionally, consider machines that can handle various blister materials to accommodate different packaging requirements.

Integration with Existing Production Lines

Seamless integration of your blister packaging machine with existing production lines is crucial for overall operational efficiency. Evaluate the machine's compatibility with your current equipment, such as cartoning machines or labeling systems. Some advanced blister packaging machines offer integrated solutions that combine multiple packaging processes, streamlining your production flow and reducing the need for separate equipment.

Optimizing Blister Packaging Design for Maximum Impact

Material Selection and Sustainability

Choosing the right materials for your blister packaging is essential for both product protection and environmental considerations. PVC remains a popular choice due to its clarity and formability, but alternatives like PET and recycled plastics are gaining traction for their eco-friendly properties. Consider using bio-based or compostable materials if they align with your sustainability goals and product requirements. Balancing material performance, cost, and environmental impact is key to creating an optimal blister packaging solution.

Customization and Branding Opportunities

Blister packaging offers numerous opportunities for product differentiation and brand reinforcement. Explore custom shapes, colors, and printing options to create eye-catching designs that stand out on shelves. Incorporate your brand elements seamlessly into the packaging design to enhance brand recognition. Consider using embossing, debossing, or holographic effects to add a premium touch to your blister packaging. Remember that effective customization should not only attract attention but also convey your product's value proposition, which can be efficiently achieved using a suitable blister packaging machine.

User Experience and Functionality

The functionality of your blister packaging plays a crucial role in user satisfaction and product protection. Design your packaging with the end-user in mind, considering factors such as ease of opening, reclosability, and portability. For pharmaceutical products, child-resistant features may be necessary. In contrast, consumer electronics might benefit from packaging that doubles as a display stand. Conduct user testing to refine your design and ensure it meets both practical and aesthetic requirements.

Conclusion

Selecting the right blister packaging for your business involves careful consideration of various factors, from material selection and blister packaging machine capabilities to design aesthetics and user experience. By understanding your product requirements, industry standards, and target audience, you can make an informed decision that enhances your product's appeal and protection. Remember that the ideal blister packaging solution should strike a balance between functionality, cost-effectiveness, and sustainability. Investing time and resources in choosing the right blister packaging can lead to improved product performance, increased customer satisfaction, and ultimately, business growth.

Contact Us

For expert guidance on selecting the perfect blister packaging solution for your business, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of packaging specialists is ready to help you optimize your packaging process and elevate your product presentation.