The Evolution of Tablet Packaging Technology

From Manual to Automated: A Brief History

Tablet packaging has undergone a significant transformation over the years. Initially, pharmacists manually counted and wrapped tablets, a slow and error-prone task that limited production capacity. To meet increasing demand, semi-automated counting trays were introduced, improving speed but still requiring manual oversight. It wasn't until the mid-20th century that fully automated packaging systems emerged, marking a major leap forward in efficiency and accuracy in pharmaceutical packaging processes.

The Rise of Blister Packaging

Blister packaging fundamentally changed how pharmaceuticals are packaged and protected. By sealing individual tablets or capsules within thermoformed plastic cavities backed by aluminum foil or paperboard, blister packs provide superior protection against moisture, oxygen, and contamination. This packaging method also offers tamper-evident security, ensuring medication integrity throughout the supply chain. Due to these advantages, blister packaging equipment quickly became standard in the pharmaceutical industry, enhancing both product safety and consumer confidence.

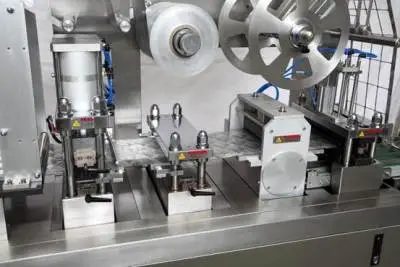

Advancements in Blister Packaging Machinery

Technological progress has driven continual improvements in blister packaging machinery. Today's machines feature high-speed capabilities that dramatically increase production rates, integrated quality control systems like vision inspection to detect defects, and the ability to handle a wide range of packaging materials. These innovations not only boost operational efficiency but also enhance product safety, traceability, and regulatory compliance, meeting the evolving demands of modern pharmaceutical manufacturing.

Types of Tablet Packing Machines and Their Applications

Blister Machine Packing: The Industry Standard

Blister machine packing is widely regarded as the preferred packaging solution within the pharmaceutical industry. These machines form individual cavities for each tablet and seal them securely to ensure optimal protection. The advantages include prolonged shelf life, effective shielding from moisture, oxygen, and contamination, and flexible packaging design options. Blister machines are available in different configurations such as rotary and flat-bed, accommodating various production volumes and diverse tablet shapes to meet industry demands.

Strip Packaging Machines: Economical and Versatile

Strip packaging machines present an economical and practical option for packaging certain pharmaceutical products. These systems produce continuous strips of sealed packets, each containing one or more tablets. While strip packaging may not offer the same robust protection against moisture as blister packs produced by a high speed blister packing machine, it is well-suited for medications that have less stringent packaging requirements. Its versatility and cost-effectiveness make strip packaging machines a valuable asset for many manufacturers.

Bottle Filling Machines: Bulk Packaging Solutions

Bottle filling machines remain the go-to equipment for packaging tablets in larger quantities, especially for over-the-counter medications. These machines efficiently fill bottles with an accurate number of tablets, often including features such as desiccant placement and tamper-evident seals. Though less suitable for unit-dose packaging compared to blister systems, bottle filling machines excel in bulk packaging, supporting high-speed production and efficient distribution channels.

Innovations in Blister Packaging Equipment

Smart Packaging Solutions

Modern blister packaging equipment integrates cutting-edge smart technologies designed to improve patient adherence and ensure product authenticity. Embedded RFID tags and NFC chips enable real-time tracking and verification of medications throughout the supply chain. Some advanced systems even incorporate electronic sensors that monitor patient usage patterns and transmit data to healthcare providers, facilitating better treatment outcomes. These innovations not only enhance safety but also support compliance with regulatory requirements and improve overall pharmaceutical management.

Sustainable Packaging Materials

Growing environmental awareness has prompted significant advancements in blister packaging materials. Manufacturers are increasingly adopting eco-friendly alternatives to traditional PVC, such as biodegradable plastics and recyclable materials that retain excellent protective qualities. These sustainable solutions reduce the ecological footprint of pharmaceutical packaging without compromising product safety or shelf life. By embracing greener materials, companies align with global sustainability goals and respond to consumer demand for environmentally responsible packaging options.

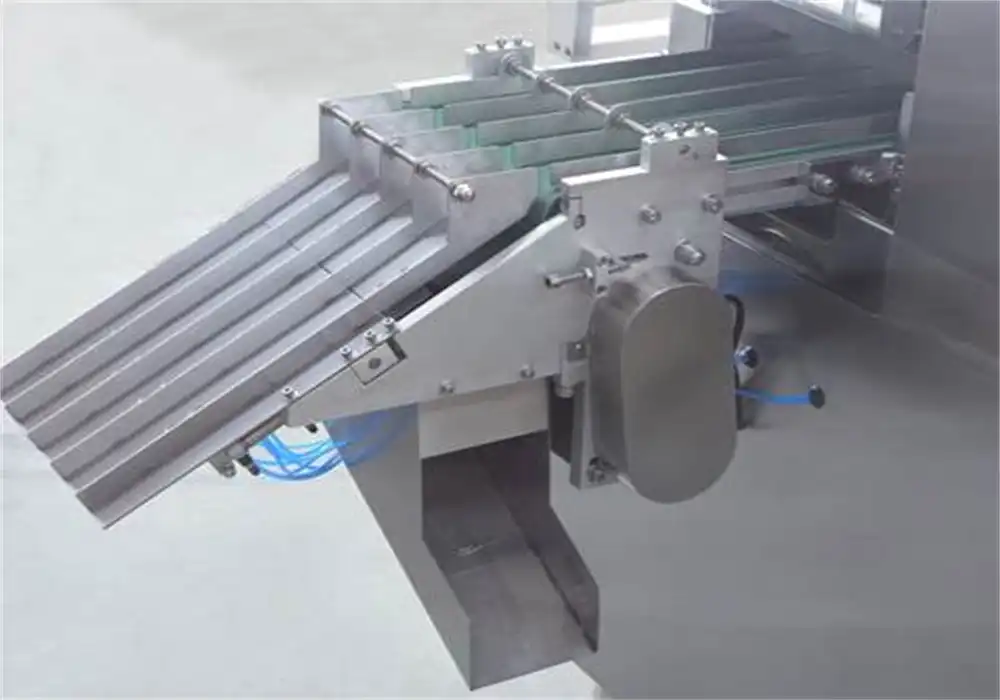

Flexibility and Quick Changeovers

Flexibility remains a key focus in the development of modern blister packaging machinery. Innovative designs feature quick-change tooling and modular components, allowing rapid adaptation to different tablet sizes, shapes, and packaging formats. This capability significantly reduces downtime during product transitions, enabling pharmaceutical manufacturers to respond swiftly to changing market demands and diverse product portfolios. Such versatility is vital for maintaining efficient production workflows and maximizing equipment utilization in a dynamic industry landscape.

Conclusion

The landscape of tablet packing machines has transformed dramatically, offering pharmaceutical companies a wide array of options to meet their specific needs. From the versatility of blister machine packing to the innovations in blister packaging equipment and machinery, these technologies continue to evolve, addressing challenges in medication safety, patient compliance, and environmental sustainability. As the pharmaceutical industry faces new challenges and opportunities, we can expect further advancements in tablet packaging solutions, driving improvements in healthcare delivery and patient outcomes.

Contact Us

For more information about our cutting-edge tablet packing machines and customized packaging solutions, please contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your pharmaceutical products.