Pharmaceutical blister packaging machines are essential equipment in the modern pharmaceutical industry, revolutionizing the way medications are packaged and protected. These sophisticated devices combine precision engineering with advanced technology to create individualized, tamper-evident packages that preserve drug efficacy and enhance patient compliance. Blister packaging machines in the pharmaceutical sector offer numerous benefits, including extended shelf life, protection against moisture and contaminants, and improved product traceability. As the demand for safer and more convenient drug packaging grows, understanding the intricacies of these machines becomes crucial for manufacturers and consumers alike.

The Evolution and Importance of Blister Packaging in Pharmaceuticals

Historical Development of Pharmaceutical Packaging

The pharmaceutical industry has come a long way in terms of packaging solutions. In the early days, medications were often dispensed in bulk or simple paper wrappings, which offered little protection against environmental factors. As scientific understanding of drug stability improved, so did the need for more sophisticated packaging methods. The introduction of blister packaging in the 1960s marked a significant milestone in pharmaceutical packaging history, providing a solution that addressed many of the industry's concerns.

Advantages of Blister Packaging for Medications

Blister packaging offers numerous advantages for pharmaceutical products. It provides an excellent barrier against moisture, oxygen, and light, which can degrade drug efficacy. Each dose is individually sealed, reducing the risk of contamination and ensuring product integrity until the moment of use. This packaging format also aids in patient compliance by organizing doses and making it easy to track medication intake. Furthermore, the tamper-evident nature of blister packs enhances drug safety and helps prevent counterfeiting, a growing concern in the global blister packaging machine pharmaceutical industry.

Regulatory Considerations in Pharmaceutical Packaging

The pharmaceutical industry is heavily regulated, and packaging plays a crucial role in meeting stringent requirements. Blister packaging machines must comply with Good Manufacturing Practice (GMP) guidelines and various international standards. These regulations ensure that the packaging process maintains the quality, safety, and efficacy of the medications. Manufacturers must also consider child-resistant and senior-friendly designs, as well as the inclusion of necessary product information and tracking codes on the packaging.

Components and Functionality of Pharmaceutical Blister Packaging Machines

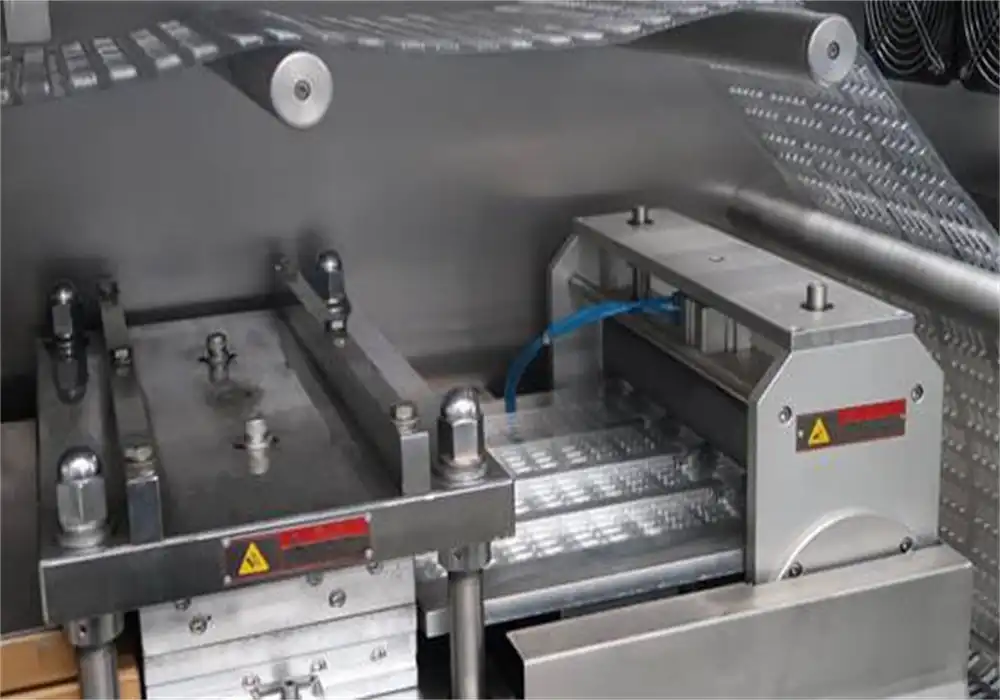

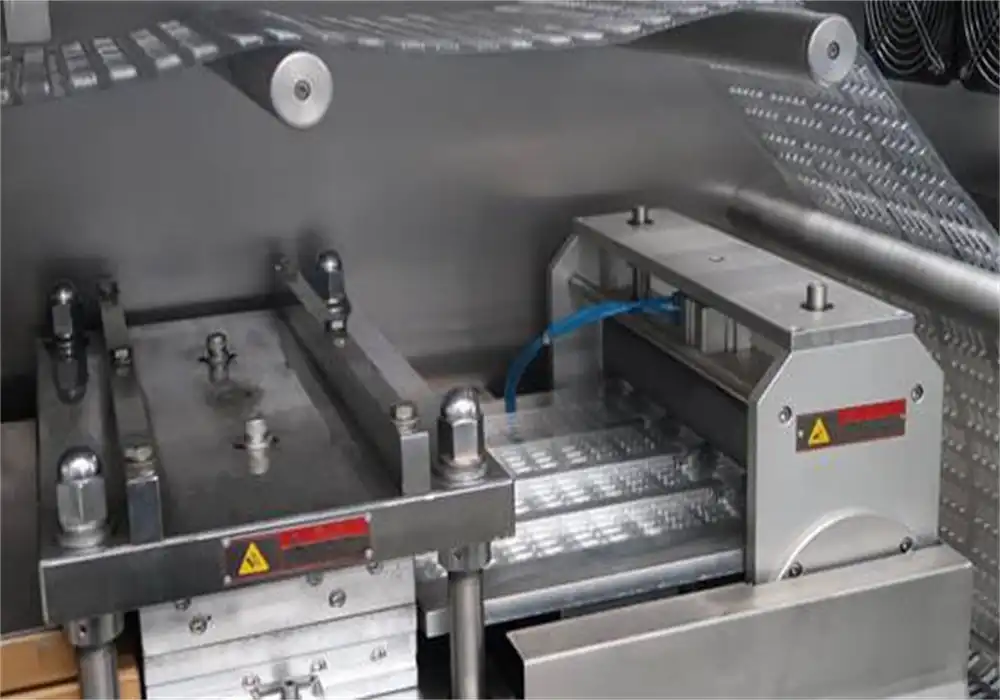

Key Components of a Blister Packaging Machine

A pharmaceutical blister packaging machine is a complex system comprised of several key components. The forming station shapes the plastic or aluminum foil into cavities that will hold the product. The filling station accurately places medications into these cavities, often using advanced vision systems for quality control. The sealing station applies the lidding material, typically aluminum foil, and seals it to the formed blisters. Additional components may include coding and printing systems for lot numbers and expiration dates, as well as perforation units for easy separation of individual doses.

Types of Blister Packaging Machines

There are various types of pharma blister packaging machines available to suit different production needs. Rotary blister machines are ideal for high-volume production, offering continuous operation and rapid output. Shuttle blister machines, on the other hand, are more suitable for smaller batches or frequent product changeovers. Some machines specialize in thermoforming, while others are designed for cold forming of aluminum blisters. The choice of machine depends on factors such as production volume, product characteristics, and packaging material requirements.

Automation and Control Systems

Modern pharmaceutical blister packaging machines incorporate sophisticated automation and control systems. These systems ensure precise timing and coordination of all machine functions, from blister formation to sealing and cutting. Servo motors and advanced sensors provide accurate control over critical parameters such as temperature, pressure, and alignment. Human-Machine Interface (HMI) panels allow operators to monitor and adjust machine settings easily. Many machines also feature integration capabilities with broader packaging lines and enterprise resource planning (ERP) systems for seamless production management.

Innovations and Future Trends in Pharmaceutical Blister Packaging Technology

Smart Packaging Solutions

The future of pharmaceutical blister packaging is increasingly intertwined with smart technology. Innovations in this area include the integration of Near Field Communication (NFC) tags and Radio-Frequency Identification (RFID) chips into blister packs. These technologies can provide real-time tracking of medication usage, send reminders to patients, and even communicate with healthcare providers. Smart packaging solutions have the potential to significantly improve patient adherence and enable more personalized healthcare approaches.

Sustainable Packaging Initiatives

As environmental concerns grow, the pharmaceutical industry is exploring more sustainable packaging options. This includes the development of biodegradable blister materials and the use of recycled content in packaging. Some manufacturers are redesigning their blister packs to reduce material usage without compromising product protection. Blister packaging machines are evolving to accommodate these new materials and designs, with features such as lower operating temperatures and gentler forming processes to work with eco-friendly substrates.

Advancements in Machine Learning and AI

Artificial Intelligence (AI) and Machine Learning (ML) are set to revolutionize pharmaceutical blister packaging machines. These technologies can enhance quality control by detecting defects that might be missed by traditional vision systems. AI can also optimize machine settings in real-time, adjusting for variations in materials or environmental conditions. Predictive maintenance algorithms can anticipate potential issues before they cause downtime, improving overall equipment effectiveness. As these technologies mature, we can expect to see even more intelligent and efficient blister packaging solutions in the pharmaceutical industry.

Conclusion

Pharmaceutical blister packaging machines play a vital role in ensuring the safety, efficacy, and convenience of medications. From their humble beginnings to the sophisticated systems of today, these machines have continuously evolved to meet the changing needs of the pharmaceutical industry and consumers. As we look to the future, innovations in smart packaging, sustainability, and artificial intelligence promise to further enhance the capabilities of blister packaging technology. For manufacturers in the pharmaceutical sector, staying informed about these advancements is crucial for maintaining competitiveness and delivering high-quality products to patients worldwide.

For more information on cutting-edge pharmaceutical blister packaging machines and customized packaging solutions, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Let us help you optimize your packaging process and ensure the highest standards of quality and efficiency for your pharmaceutical products.

References

Johnson, M. (2022). "The Evolution of Pharmaceutical Packaging: From Bottles to Blisters." Journal of Drug Delivery Science and Technology, 68, 103-115.

Smith, A., & Brown, B. (2021). "Smart Packaging in Pharmaceuticals: Enhancing Patient Adherence through Technology." International Journal of Pharmaceutics, 592, 120-132.

Lee, C. H., & Wong, D. (2023). "Sustainable Materials for Pharmaceutical Blister Packaging: A Comprehensive Review." Packaging Technology and Science, 36(4), 421-438.

Patel, R., & Garcia, S. (2022). "Application of Artificial Intelligence in Pharmaceutical Packaging Processes." Journal of Pharmaceutical Innovation, 17(2), 215-229.

Wilson, K. (2021). "Regulatory Challenges and Opportunities in Pharmaceutical Packaging." Drug Safety, 44(8), 875-889.

Zhang, L., & Thompson, E. (2023). "Advancements in Blister Packaging Machine Design for Improved Efficiency and Flexibility." International Journal of Advanced Manufacturing Technology, 124, 1587-1602.