The Evolution of Box Wrapping Machines for Sustainable Packaging

Technological Advancements in Film Compatibility

In response to increasing environmental concerns and market demand for sustainable packaging, box wrapping machines have experienced remarkable technological progress. Modern models are now equipped with highly adaptable film handling systems designed to accommodate a wide range of eco-friendly materials, including biodegradable plastics, recyclable films, and compostable wraps. These machines feature precision-adjustable tension controls, variable temperature settings, and customizable sealing systems that can be fine-tuned according to the specific composition, thickness, and strength of each film type. Such advancements allow manufacturers to maintain high-speed, reliable packaging operations while seamlessly integrating greener materials, supporting both operational efficiency and corporate sustainability initiatives.

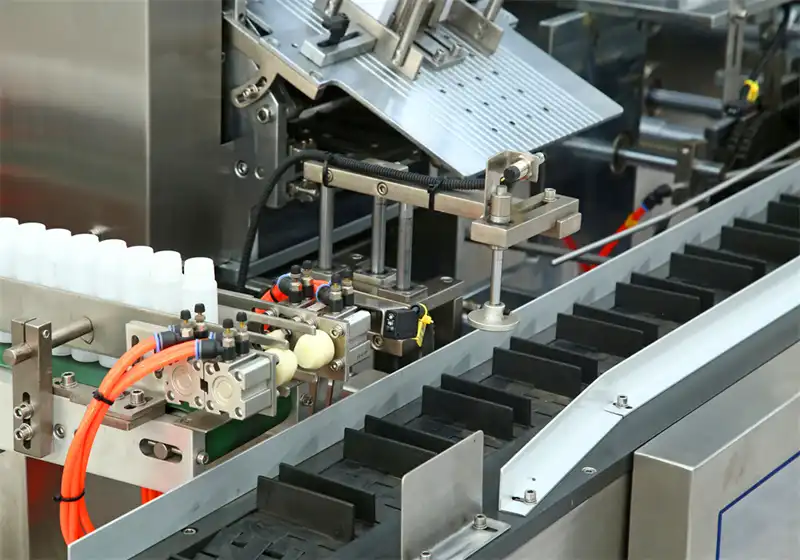

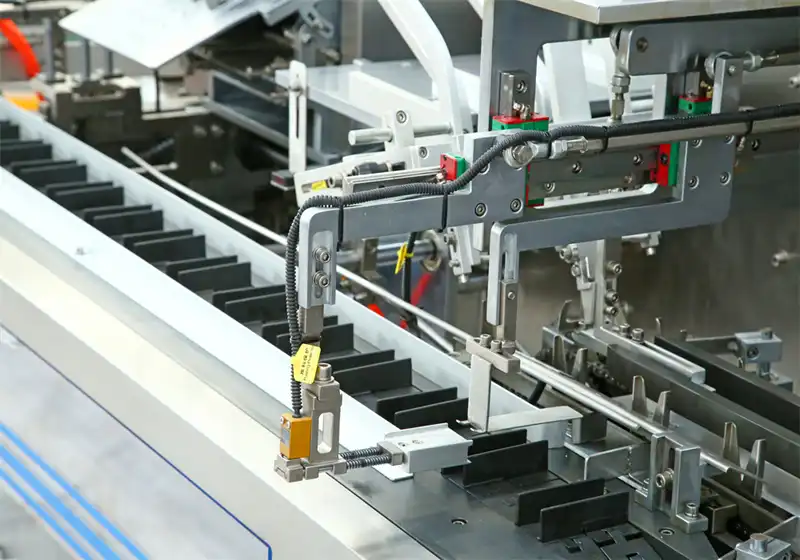

Integration of Smart Sensors and Adaptive Systems

To enhance operational consistency and compatibility with eco-friendly films, the latest box wrapping machines now incorporate advanced smart sensors and adaptive control systems. These intelligent technologies enable the machines to automatically identify critical properties of the film being processed, such as thickness, stretchability, and tensile strength. Once detected, the machine dynamically adjusts operational parameters including tension, sealing temperature, and wrapping speed to suit the material’s characteristics. This automation improves overall wrapping efficiency, minimizes material waste, and ensures reliable sealing quality. By maintaining consistent performance across various eco-conscious film types, these systems support sustainable packaging operations without compromising productivity or product protection.

Energy-Efficient Design for Reduced Carbon Footprint

Modern packaging equipment manufacturers, such as Zhejiang Haizhong Machinery Co., Ltd., have made energy efficiency a central focus in their box wrapping machine designs. By integrating advanced motor technologies, optimized heating systems, and intelligent power management modules, these machines now consume significantly less energy during operation. Enhanced insulation, heat recovery systems, and low-power standby modes further contribute to reduced energy consumption without sacrificing output speed or sealing accuracy. This emphasis on energy-efficient design perfectly complements the use of environmentally friendly films, collectively lowering the carbon footprint of packaging operations and aligning with global sustainability goals pursued by progressive manufacturers.

Eco-Friendly Film Options Compatible with Box Wrapping Machines

Biodegradable Polylactic Acid (PLA) Films

PLA films, derived from renewable resources such as corn starch or sugarcane, have gained popularity in sustainable packaging. Modern box wrapping machines are calibrated to work effectively with PLA films, adjusting heat levels and tension to prevent film degradation during the wrapping process. These machines ensure that the unique properties of PLA films are preserved while achieving secure and attractive packaging results.

Recycled and Recyclable Polyethylene Films

Advanced box wrapping equipment supports the use of recycled polyethylene films, which help close the loop in plastic recycling. These machines are designed to handle the slight variations in thickness and strength that can occur in recycled materials. Additionally, they can process films made from virgin polyethylene that are specifically designed for easy recycling, supporting a circular economy approach to packaging.

Compostable Cellulose-Based Films

Cellulose-based films, which are fully compostable, represent another eco-friendly option compatible with modern box wrapping machines. These films require precise temperature control and careful handling to maintain their integrity during the wrapping process. State-of-the-art machines are equipped with specialized sensors and adjustable parameters to ensure optimal performance with these delicate yet environmentally friendly materials.

Maximizing Efficiency and Sustainability with Box Wrapping Machines

Optimizing Film Usage and Reducing Waste

Leading box wrapping machines are designed with sustainability in mind, featuring advanced film management systems that minimize waste. These systems include precise film tensioning mechanisms, intelligent cut-off controls, and film splicing capabilities that allow for continuous operation with minimal material loss. By optimizing film usage, these machines not only reduce waste but also lower the overall cost of packaging materials, making eco-friendly options more economically viable for businesses.

Customizable Wrapping Patterns for Material Efficiency

Modern box wrapping equipment offers customizable wrapping patterns that can be tailored to different product sizes and shapes. This flexibility allows operators to achieve optimal coverage and protection while using the least amount of film possible. By fine-tuning the wrapping pattern, businesses can significantly reduce their film consumption without compromising on package integrity, further enhancing the sustainability of their packaging processes.

Integration with Sustainable Packaging Workflows

Box wrapping machines from industry leaders like Zhejiang Haizhong Machinery Co., Ltd. are designed to seamlessly integrate into broader sustainable packaging workflows. These machines can be part of fully automated packaging lines that incorporate other eco-friendly solutions such as recycled cardboard box formers, biodegradable void fill dispensers, and energy-efficient conveyor systems. This holistic approach to sustainable packaging ensures that the benefits of using eco-friendly films are maximized throughout the entire packaging process.

Conclusion

Box wrapping machines have evolved significantly to support the use of eco-friendly films, offering businesses a powerful tool in their sustainability initiatives. With advanced features like adaptive tensioning, precise temperature control, and waste reduction mechanisms, these machines enable efficient and effective use of biodegradable, recyclable, and compostable packaging materials. As the packaging industry continues to prioritize environmental responsibility, investing in versatile and eco-friendly box wrapping solutions becomes increasingly crucial for forward-thinking companies aiming to reduce their ecological footprint while meeting modern packaging demands.

Contact Us

Ready to enhance your packaging operations with eco-friendly solutions? Contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected] to explore our range of advanced box wrapping machines designed for sustainable packaging excellence.