Understanding Automatic Blister Packing Machines

The Evolution of Blister Packaging Technology

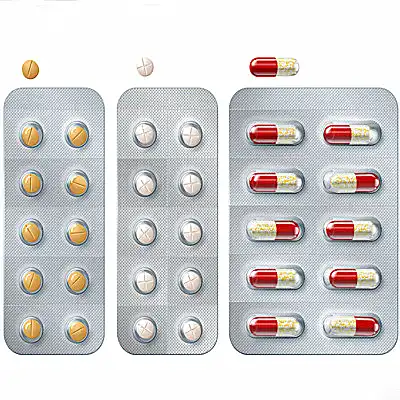

Automatic blister packing machines have revolutionized the packaging industry, offering high-speed, precision-driven solutions for businesses of all sizes. These advanced machines integrate cutting-edge technology to streamline the packaging process, significantly reducing manual labor and improving overall efficiency. As the demand for tamper-evident and shelf-stable packaging continues to grow, automatic blister packing machines have become indispensable in various sectors, including pharmaceuticals, cosmetics, and consumer goods.

Key Components of Automatic Blister Packing Systems

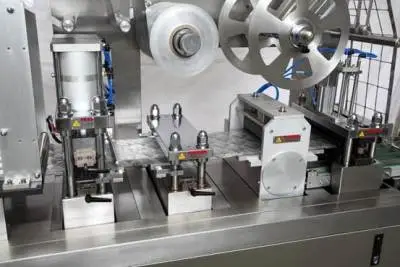

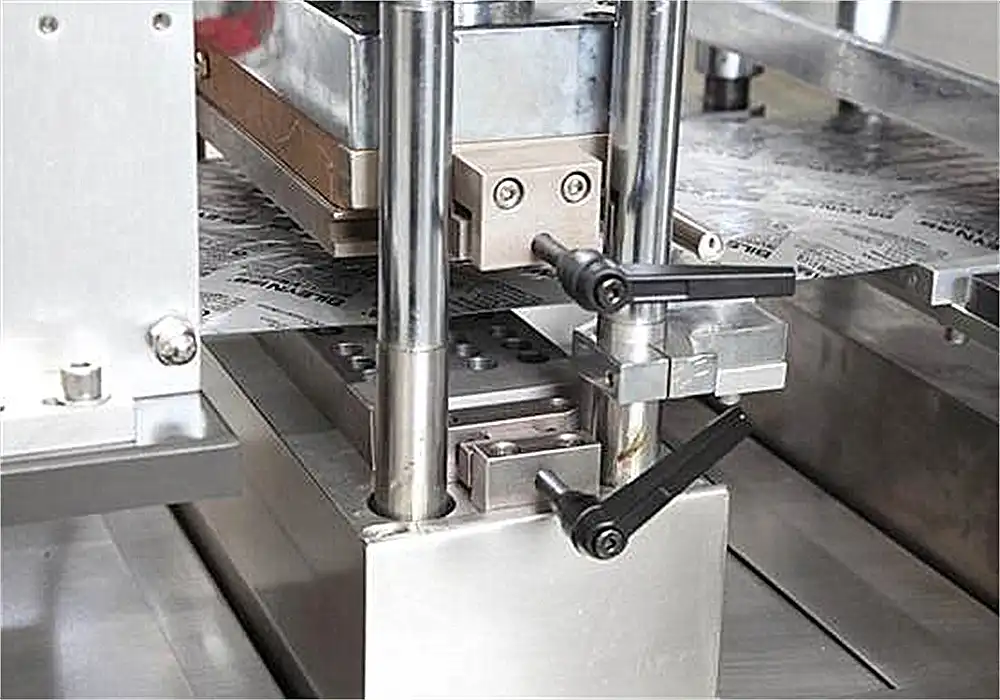

Modern automatic blister packing machines comprise several sophisticated components working in harmony to deliver seamless packaging solutions. The forming station shapes the plastic or aluminum material into precise cavities, while the filling station accurately places products into these cavities. The sealing station then applies heat and pressure to bond the formed material with the backing, creating a secure seal. Additional features such as coding systems, vision inspection, and integrated robotics further enhance the capabilities of these machines, ensuring consistent quality and traceability throughout the packaging process.

Benefits of Implementing Automatic Blister Packaging

Implementing automatic blister packaging offers numerous advantages for manufacturers. These machines significantly increase production output, with some models capable of producing thousands of blister packs per hour. The precision and consistency achieved by automatic systems result in higher quality packaging, reducing waste and enhancing product protection. Additionally, automatic blister packing machines are highly versatile, accommodating various product sizes and shapes with minimal changeover time. This flexibility allows manufacturers to adapt quickly to changing market demands and product lines, ultimately improving their competitive edge in the industry.

Exploring Pharma Blister Packing Machines

Specialized Features for Pharmaceutical Packaging

Pharma blister packing machines are specifically designed to meet the stringent requirements of the pharmaceutical industry. These specialized machines incorporate features that ensure product integrity, maintain sterility, and comply with regulatory standards. Advanced sealing technologies, such as cold forming for aluminum blisters, protect moisture-sensitive medications. Integrated track-and-trace systems enable serialization and anti-counterfeiting measures, crucial for maintaining the integrity of the pharmaceutical supply chain. Pharma blister packing machines also often include cleanroom-compatible designs and materials that adhere to cGMP (current Good Manufacturing Practice) guidelines.

Compliance with Regulatory Standards

The pharmaceutical industry is heavily regulated, and pharma blister packing machines play a vital role in ensuring compliance. These machines are designed to meet various international standards, including FDA, EMA, and WHO guidelines. They incorporate features such as integrated vision systems for 100% inspection, reject mechanisms for defective packs, and data logging capabilities for comprehensive batch records. By utilizing pharma blister packing machines, manufacturers can demonstrate their commitment to quality and regulatory compliance, facilitating easier approvals and market access for their products.

Innovations in Pharmaceutical Blister Packaging

The pharmaceutical packaging landscape is constantly evolving, driven by the need for enhanced patient safety, improved adherence, and sustainable solutions. Recent innovations in pharma blister packing machines include the integration of smart packaging technologies, such as NFC tags and printed electronics, enabling interactive patient experiences and improved medication management. Eco-friendly blister materials and designs are also gaining traction, with machines adapted to handle biodegradable films and recyclable backing materials. Additionally, advancements in machine learning and artificial intelligence are being incorporated into pharma blister packing machines, optimizing production parameters and predictive maintenance schedules.

Choosing the Right Blister Pack Machine for Your Needs

Assessing Production Requirements

Selecting the appropriate blister pack machine begins with a thorough assessment of your production requirements. Consider factors such as desired output capacity, product dimensions and characteristics, and packaging material specifications. Evaluate whether a fully automatic system is necessary or if a semi-automatic solution would suffice for your current and projected needs. It's also crucial to consider the flexibility of the machine, especially if you anticipate frequent product changeovers or plan to expand your product line in the future. By carefully analyzing these aspects, you can identify a blister pack machine that aligns with your operational goals and budget constraints.

Evaluating Machine Features and Capabilities

When comparing blister pack machines, it's essential to evaluate the specific features and capabilities offered by different models. Look for machines with robust construction and high-quality components to ensure longevity and reliability. Consider the range of blister formats and materials the machine can handle, as well as its ability to integrate with existing production lines or auxiliary equipment. Advanced features such as servo-driven systems, quick-change tooling, and user-friendly HMI interfaces can significantly enhance operational efficiency and reduce downtime. Additionally, assess the automatic blister packing machine's footprint and energy consumption to ensure it fits within your facility's constraints and aligns with sustainability goals.

Importance of After-Sales Support and Training

The success of implementing a new blister pack machine extends beyond the initial purchase and installation. When selecting a machine supplier, consider the level of after-sales support and training they offer. Look for providers with a strong track record of customer service, readily available spare parts, and comprehensive technical support. Adequate training for operators and maintenance personnel is crucial for maximizing the machine's potential and ensuring smooth operation. Some suppliers offer remote diagnostics and predictive maintenance services, which can significantly reduce downtime and extend the machine's lifespan. By prioritizing robust after-sales support, you can protect your investment and optimize the long-term performance of your blister packaging operations.

Conclusion

Blister pack machines play a crucial role in modern packaging operations, offering versatile solutions for a wide range of industries. From automatic blister packing machines that boost productivity to specialized pharma blister packing machines that ensure compliance and product integrity, these systems continue to evolve to meet the changing demands of manufacturers and consumers alike. By understanding the different types of blister pack machines and carefully evaluating your specific needs, you can select the ideal equipment to enhance your packaging processes, improve product protection, and ultimately drive business success in today's competitive market landscape.

Contact Us

Ready to elevate your packaging operations with state-of-the-art blister pack machines? Contact Zhejiang Haizhong Machinery Co.,Ltd. today at [email protected] to explore our range of innovative packaging solutions tailored to your specific requirements.