Understanding Biscuit Cartoning Machines: Types and Technologies

Horizontal vs. Vertical Cartoning Machines

When delving into the world of biscuit packaging, it's crucial to understand the two main types of cartoning machines: horizontal and vertical. Horizontal cartoning machines are ideal for products that are already in a horizontal orientation, such as stacked biscuits. These machines excel at handling delicate products and offer high-speed operation. Vertical cartoning machines, on the other hand, are perfect for products that naturally fall into a vertical position, like bags of biscuits. They're known for their compact footprint and versatility in handling various product sizes.

Intermittent vs. Continuous Motion Technology

The motion technology employed in cartoning machines significantly impacts their speed and efficiency. Intermittent motion machines operate in a start-stop manner, making them suitable for lower production volumes and more delicate products. Continuous motion machines, as the name suggests, operate without pausing, allowing for higher speeds and increased output. When selecting a biscuit cartoning machine, consider your production volume and the fragility of your products to determine which technology aligns best with your needs.

Smart Features and Integration Capabilities

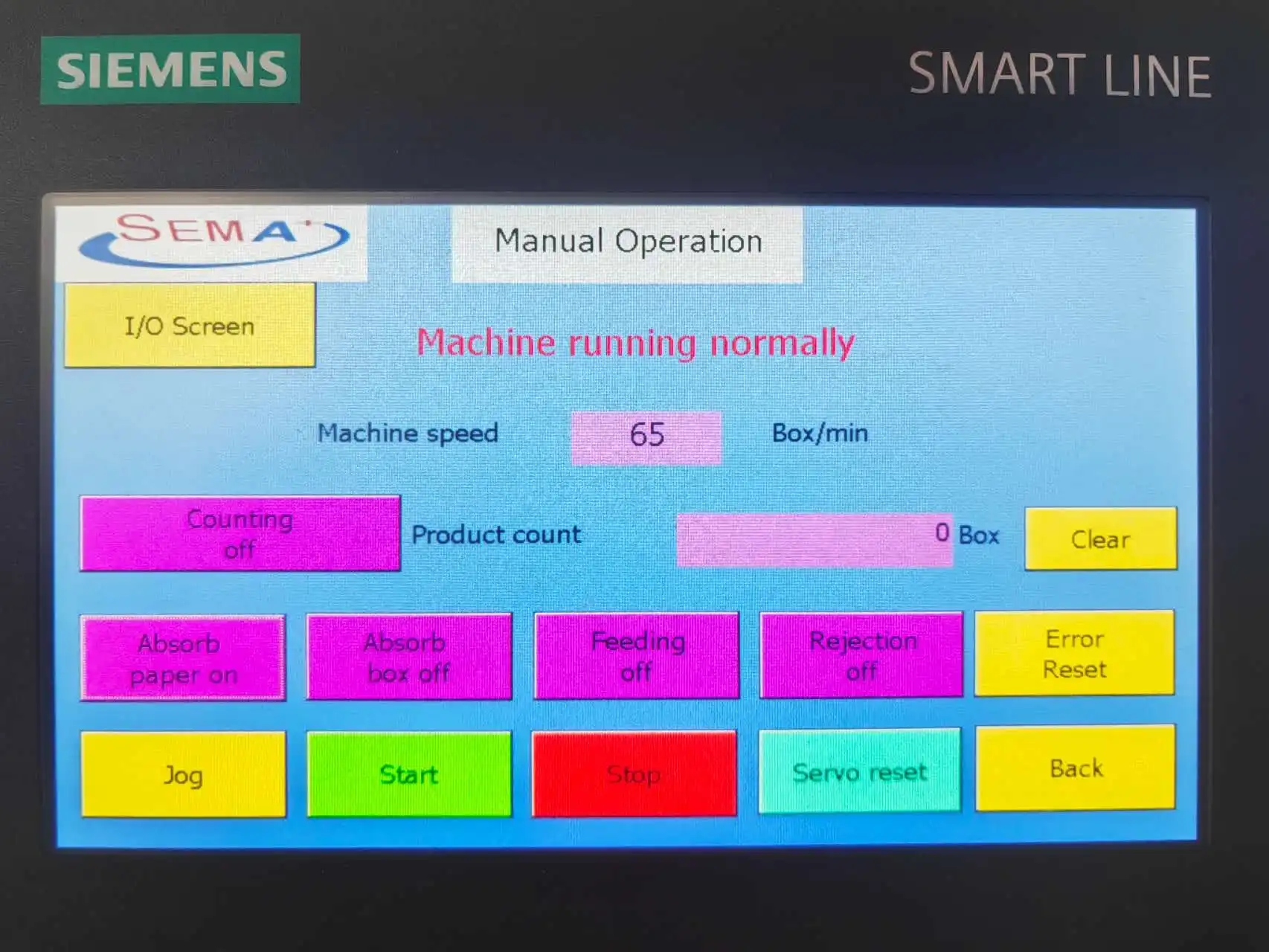

Modern automatic cartoning machines come equipped with advanced features that enhance their performance and ease of use. Look for machines with user-friendly HMI (Human-Machine Interface) systems, which simplify operation and troubleshooting. Additionally, consider machines with IoT (Internet of Things) capabilities, allowing for remote monitoring and predictive maintenance. Integration capabilities are also crucial, ensuring your cartoning machine can seamlessly connect with other equipment in your production line, such as flow wrappers or checkweighers.

Key Considerations for Selecting the Right Biscuit Cartoning Machine

Production Speed and Capacity Requirements

One of the primary factors to consider when choosing a biscuit cartoning machine is its production speed and capacity. Assess your current production needs and factor in potential future growth. It's essential to select a machine that can handle your peak production demands without compromising on quality. Remember, faster isn't always better – the optimal speed should balance efficiency with product handling care to prevent damage to your biscuits.

Carton Size Flexibility and Changeover Time

In the dynamic world of biscuit packaging, versatility is key. Look for an automatic cartoning machine that offers flexibility in terms of carton sizes and styles. Quick and easy changeover capabilities are crucial, especially if you produce a variety of biscuit products. Machines with tool-less changeovers and memory-stored settings for different carton sizes can significantly reduce downtime and improve overall efficiency.

Material Handling and Product Protection

Biscuits are delicate products that require gentle handling throughout the packaging process. Evaluate the cartoning machine's feeding system and product transfer mechanisms to ensure they can handle your biscuits without causing breakage or damage. Look for features like servo-driven systems that offer precise control and smooth movements. Additionally, consider machines with carton forming and closing systems that create secure, tamper-evident packages to protect your products during distribution and on store shelves.

Maximizing ROI: Maintenance, Support, and Future-Proofing Your Investment

Preventive Maintenance and Spare Parts Availability

To ensure the longevity and consistent performance of your biscuit cartoning machine, prioritize equipment with accessible maintenance features and readily available spare parts. Look for machines designed with easy-to-clean components and modular construction, facilitating quick maintenance and minimizing downtime. Inquire about the manufacturer's spare parts inventory and their ability to provide rapid support. A well-maintained cartoning machine not only operates more efficiently but also extends the lifespan of your investment.

Technical Support and Training Programs

The complexity of modern automatic cartoning machines necessitates comprehensive technical support and training. When evaluating potential suppliers, consider their after-sales service offerings, including on-site technical support, remote troubleshooting capabilities, and operator training programs. A supplier that provides thorough training ensures your team can maximize the machine's potential and address minor issues independently, reducing reliance on external support and minimizing production disruptions.

Scalability and Future-Proofing Considerations

As your biscuit production evolves, your packaging needs may change. Opt for a cartoning machine that offers scalability and adaptability to future requirements. This might include the ability to upgrade speed capabilities, integrate new technologies, or handle different carton styles. Additionally, consider the machine's potential to integrate with Industry 4.0 technologies, such as data analytics and automation systems, to future-proof your investment and maintain competitiveness in the rapidly advancing packaging industry.

Conclusion

Selecting the right biscuit cartoning machine is a critical decision that impacts your production efficiency, product quality, and overall business success. By carefully considering factors such as machine type, production requirements, flexibility, and long-term support, you can make an informed choice that aligns with your specific needs. Remember, the ideal cartoning machine is not just about meeting current demands but also about positioning your business for future growth and adaptation to market changes. Invest time in thorough research, engage with reputable suppliers, and don't hesitate to request demonstrations or trials before making your final decision.

Contact Us

Ready to take the next step in optimizing your biscuit packaging process? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] for expert advice and tailored solutions to meet your specific cartoning needs. Our team of packaging specialists is ready to help you find the perfect automatic cartoning machine for your biscuit production line.