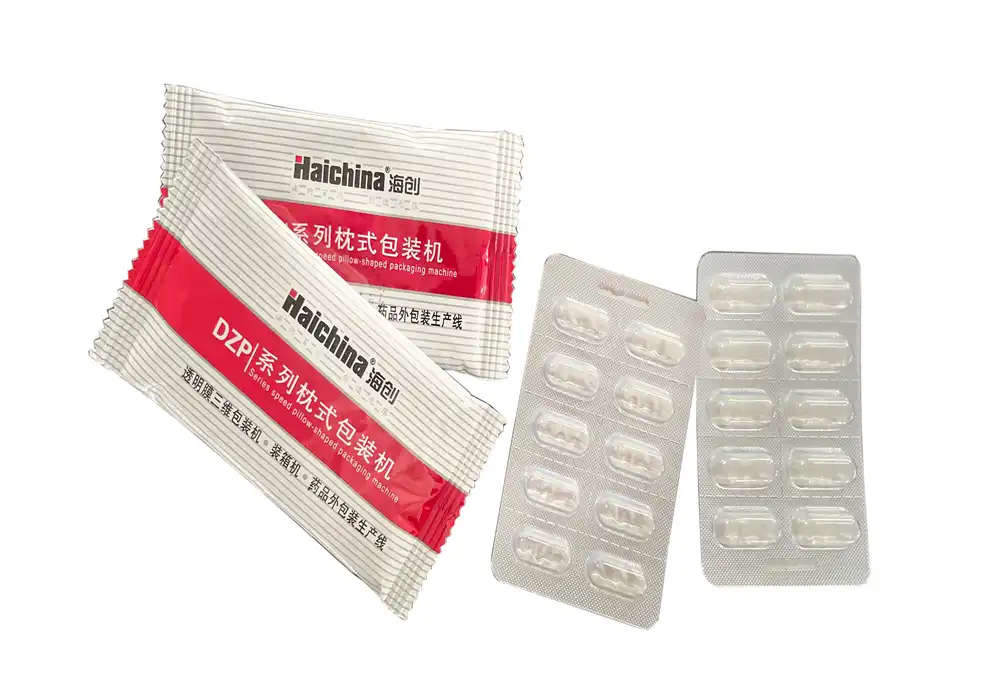

Flow Packing Machine for Retail Packaging

Flow packing machines have revolutionized the retail packaging industry, offering efficient and versatile solutions for a wide range of products. These machines automate the process of wrapping items in flexible film, creating attractive and secure packages that catch consumers' eyes on store shelves. From food items to cosmetics and household goods, flow pack packaging enhances product presentation, extends shelf life, and streamlines production processes. As retailers seek cost-effective and appealing packaging options, flow packing machines have become indispensable tools in modern manufacturing and packaging facilities.

The Mechanics and Benefits of Flow Packing Machines

How Flow Packing Machines Work

Flow packing machines operate on a continuous motion principle, seamlessly transforming flat film into tubular packaging around products. The process begins as items are fed onto a conveyor belt, which carries them to the forming box. Here, the packaging film is shaped into a tube around the product. Seal bars then create longitudinal and transverse seals, effectively enclosing the item. The machine's precision cutting mechanism separates individual packages, resulting in neatly wrapped products ready for distribution.

Advantages of Flow Packing for Retail Products

Retail businesses benefit significantly from flow packing technology. These machines offer unparalleled flexibility, accommodating various product sizes and shapes with minimal changeover time. The hermetic seals produced by flow packers ensure product freshness and integrity, crucial for food items and perishables. Moreover, the sleek, professional appearance of flow-packed products enhances shelf appeal, potentially boosting sales. The high-speed operation of modern flow packers also contributes to increased productivity, allowing manufacturers to meet demanding production schedules efficiently.

Customization Options in Flow Packing

One of the most compelling aspects of flow packing machines is their adaptability. Manufacturers can customize packaging materials, selecting from a range of films with different properties such as barrier protection, transparency, or eco-friendliness. Advanced models offer options for modified atmosphere packaging (MAP), extending product shelf life further. Additionally, integrated printing systems allow for on-the-fly date coding, batch numbering, and even promotional messaging, enhancing traceability and marketing potential without slowing down the packaging process.

Selecting the Right Flow Packing Machine for Your Retail Needs

Assessing Production Requirements

When selecting a flow packing machine, the first step is evaluating your production demands. This involves considering the size and shape of the products to be packaged, as well as the packaging materials required for optimal performance. Larger businesses with high-volume needs may find multi-lane machines more efficient, as they offer faster speeds and increased productivity. On the other hand, smaller operations might prioritize compact, flexible models that are adaptable to varying products. Furthermore, it's important to plan for future scalability—ensuring the chosen machine can grow with your business without necessitating frequent replacements or upgrades.

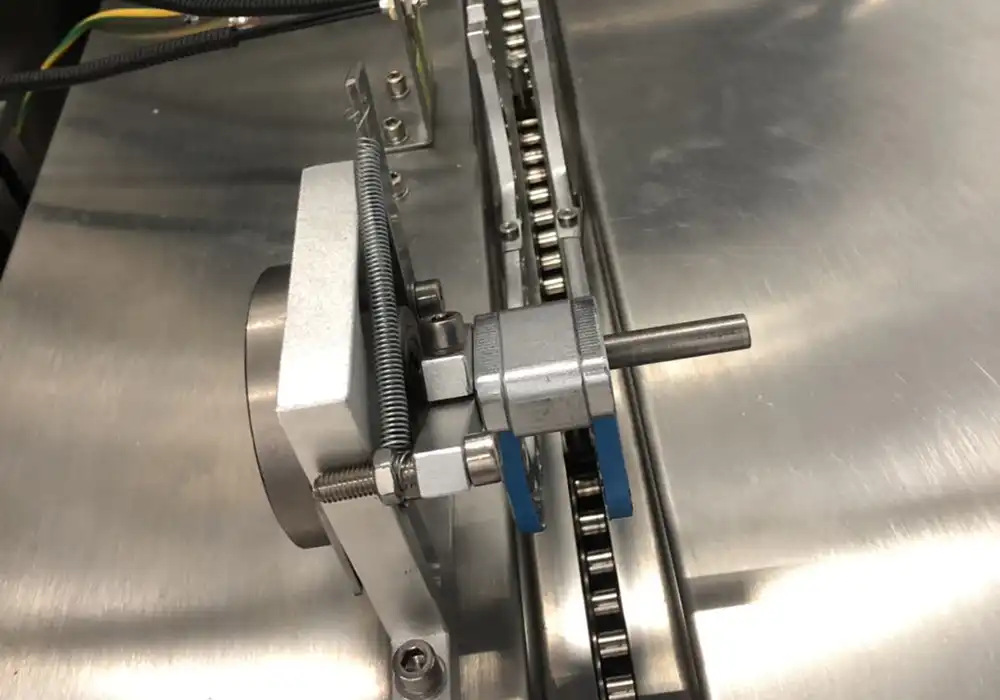

Technical Specifications to Consider

The technical aspects of flow packing machines are crucial to their efficiency and long-term performance. Servo-driven systems are often favored for their precise motion control, delivering smoother operations and reducing wear and tear. Pay attention to sealing technologies as well—specific products might require particular heat or pressure settings to maintain packaging integrity. The user interface is another key factor, as a simple, intuitive control panel can drastically reduce operator errors and improve workflow. Features such as quick-change tooling and remote diagnostics can significantly cut downtime and enhance operational uptime, ensuring a more reliable production line.

Integration with Existing Production Lines

A smooth integration with your existing production line is vital for optimizing workflow and reducing operational friction. The flow packing machine you choose should be compatible with existing conveyors and upstream or downstream equipment, allowing for seamless coordination. Look for systems that are designed to integrate effortlessly into your facility’s layout, minimizing disruptions to current operations. In some cases, manufacturers offer turnkey solutions that include all necessary components, ensuring they work together as a cohesive system. It’s also essential to account for the machine's footprint, ensuring it fits within your production area without causing space constraints.

Maximizing Efficiency and ROI with Flow Packing Technology

Optimizing Machine Performance

To extract maximum value from your flow packing investment, focus on optimizing machine performance. Regular maintenance schedules, including lubrication and wear part replacement, are essential for consistent operation. Train operators thoroughly in machine setup and troubleshooting to minimize downtime. Utilize data logging and analytics features, if available, to identify bottlenecks and refine production parameters. Implementing lean manufacturing principles in conjunction with your flow packing operations can further enhance overall efficiency and reduce waste.

Sustainable Packaging Solutions

As environmental concerns become increasingly important to consumers, consider how your flow packing machine can support sustainable packaging initiatives. Many modern machines are compatible with eco-friendly films, including biodegradable and compostable options. Some models offer film-saving features that reduce material usage without compromising package integrity. Explore opportunities to minimize packaging thickness or implement easy-open designs that reduce plastic waste. By aligning your packaging strategy with sustainability goals, you can appeal to environmentally conscious consumers while potentially reducing material costs.

Future-Proofing Your Packaging Operations

The packaging industry is constantly evolving, driven by technological advancements and changing consumer preferences. When investing in a flow packing machine, consider its adaptability to future trends. Look for machines with modular designs that allow for easy upgrades or reconfiguration. Some advanced models offer IoT connectivity, enabling remote monitoring and predictive maintenance capabilities. Stay informed about emerging packaging materials and technologies, and choose a machine that can accommodate potential shifts in your product line or packaging requirements. By selecting a forward-thinking solution, you can ensure your packaging operations remain competitive and efficient for years to come.

Conclusion

Flow packing machines represent a cornerstone of modern retail packaging, offering unparalleled flexibility, efficiency, and product protection. By carefully selecting the right machine for your specific needs and optimizing its performance, you can significantly enhance your packaging operations. As the industry continues to evolve, embracing sustainable solutions and staying adaptable will be key to maintaining a competitive edge. With the right approach, flow packing technology can drive substantial improvements in productivity, product presentation, and ultimately, your bottom line.

Contact Us

To learn more about how flow packing machines can transform your retail packaging operations, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your business needs.

References

Smith, J. (2022). Advances in Retail Packaging Technology: A Comprehensive Guide.

Johnson, A. et al. (2021). Sustainable Packaging Solutions for the Modern Retail Environment.

Brown, R. (2023). Optimizing Production Efficiency with Flow Packing Machines.

Lee, S. (2022). The Impact of Packaging on Consumer Behavior in Retail Settings.

García, M. (2023). Industry 4.0 and the Future of Packaging Automation.

Wilson, T. (2021). Material Innovations in Flexible Packaging for Retail Products.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?