The Evolution of Pet Food Packaging Technology

Traditional Packaging Methods

In the early days of pet food production, packaging options were limited. Manufacturers relied on manual bagging processes or rudimentary filling machines. These methods were time-consuming, labor-intensive, and often resulted in inconsistent package sizes and seals. As the pet food industry grew, the need for more efficient packaging solutions became apparent.

Introduction of Automated Packaging Systems

The advent of automated packaging systems marked a significant turning point in the pet food industry. Early machines offered basic filling and sealing capabilities, improving production speeds and package uniformity. However, these systems still had limitations in terms of flexibility and product handling.

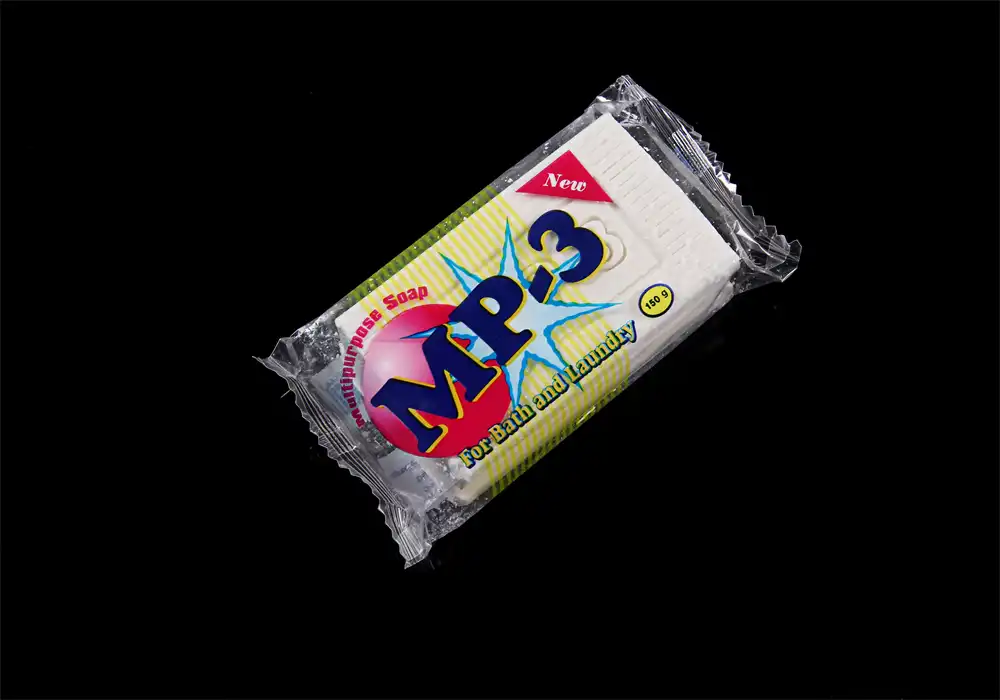

Rise of Flow Wrap Technology

Flow wrap machines emerged as a game-changer in pet food packaging. These innovative systems introduced a continuous packaging process that could handle a wide range of product sizes and shapes. The ability to create hermetically sealed packages with high-speed efficiency revolutionized production capabilities and opened new possibilities for product presentation and preservation.

Key Features and Benefits of Flow Wrap Machines for Pet Food

Versatility in Product Handling

Flow wrap machines stand out for their remarkable versatility in handling a wide range of pet food products. Whether packaging dry kibble, crunchy biscuits, soft treats, or chews, these machines can accommodate various textures and sizes efficiently. Their adjustable product infeed systems and flexible film forming components enable swift changeovers between different products. This adaptability not only maximizes production efficiency but also reduces downtime, making these machines ideal for dynamic production environments with diverse packaging needs.

High-Speed Operation

Designed to meet the demands of large-scale pet food manufacturing, modern flow wrap machines operate at impressive speeds, often producing hundreds of packages per minute. The integration of advanced servo-driven systems allows for precise control over critical parameters such as film tension, sealing temperature, and cutting accuracy. This ensures that, even at high speeds, packaging quality remains consistent and reliable, supporting both productivity and product integrity on busy production lines.

Enhanced Product Protection

Flow wrap machines provide excellent protection for pet food products by creating secure, airtight packages. The continuous packaging process produces strong seals that prevent exposure to moisture, oxygen, and contaminants, thereby preserving product freshness and quality. Many machines also support modified atmosphere packaging (MAP), replacing the air inside packages with inert gases to extend shelf life further. This feature is especially beneficial for maintaining the nutritional value and taste of pet food over time.

Innovations in Flow Wrap Technology for Pet Food Packaging

Sustainable Packaging Solutions

With growing environmental awareness, flow wrap machine manufacturers have introduced innovations that support sustainable packaging practices. Many modern machines are designed to work seamlessly with eco-friendly materials such as biodegradable films and recyclable laminates. These advancements enable pet food producers to minimize their ecological footprint while preserving product freshness and visual appeal. By integrating sustainable materials, companies can meet consumer demand for greener packaging without compromising on functionality or shelf life.

Integration of Smart Technology

Recent flow wrap machines are equipped with smart technologies that enhance both production efficiency and quality assurance. Advanced sensors continuously monitor machine performance and product quality, providing operators with real-time feedback. Some systems include predictive maintenance features that anticipate potential failures, helping to reduce unplanned downtime. This technological integration improves operational reliability and ensures consistent packaging standards, contributing to smoother production workflows and higher overall equipment effectiveness.

Customization and Flexibility

Flow wrap machines today offer a high degree of customization to address the varied needs of the pet food market. Features like adjustable film widths, customizable seal patterns, and integrated labeling or coding options allow manufacturers to tailor packaging precisely to product and brand requirements. This flexibility supports innovative package designs that attract consumer attention and accommodate different portion sizes or formats. Such adaptable solutions help pet food brands stay competitive and responsive to evolving market trends.

Conclusion

Flow wrap machines have become an integral part of the pet food packaging industry, offering unparalleled efficiency, versatility, and product protection. As technology continues to advance, these machines are evolving to meet the changing demands of manufacturers and consumers alike. With their ability to handle a wide range of products, create attractive packaging, and support sustainable initiatives, flow wrap machines are poised to remain at the forefront of pet food packaging solutions for years to come.

FAQs

What types of pet food can be packaged using flow wrap machines?

Flow wrap machines can package a wide variety of pet food products, including dry kibble, treats, biscuits, and soft chews.

How do flow wrap machines contribute to product freshness?

These machines create hermetically sealed packages that protect against moisture and air, helping to maintain product freshness and extend shelf life.

Are flow wrap machines suitable for small-scale pet food producers?

Yes, there are flow wrap machines available in various sizes and capacities, making them suitable for both small-scale and large-scale production.

Why Choose Flow Wrap Machines for Pet Food Packaging | Haichina?

Haichina, a leading manufacturer of packaging equipment, offers state-of-the-art flow wrap machines tailored for the pet food industry. Our machines combine high-speed operation with precision control, ensuring efficient and reliable packaging solutions. With customizable features, compatibility with eco-friendly materials, and adherence to strict quality standards, Haichina's flow wrap machines are the ideal choice for pet food manufacturers seeking to optimize their packaging processes. Contact our experienced team at [email protected] to discover how our innovative solutions can elevate your pet food packaging operations.

References

Johnson, M. (2022). Advancements in Pet Food Packaging Technology. Journal of Food Processing and Packaging, 15(3), 78-92.

Smith, A. R., & Brown, L. K. (2021). Sustainable Packaging Solutions for the Pet Food Industry. International Journal of Sustainable Packaging, 8(2), 112-127.

Thompson, E. G. (2023). The Impact of Flow Wrap Technology on Pet Food Shelf Life. Food Quality and Preservation Review, 12(4), 203-218.

Wilson, C. D., et al. (2022). Comparative Analysis of Packaging Methods in the Pet Food Sector. Journal of Industrial Packaging, 19(1), 45-60.

Zhang, Y., & Lee, S. H. (2023). Smart Manufacturing in Pet Food Packaging: A Case Study of Flow Wrap Machines. Automation in Food Processing, 7(2), 89-104.

Patel, R. K. (2021). Consumer Preferences in Pet Food Packaging: Implications for Manufacturers. Market Trends in Pet Care, 14(3), 167-182.