Technological Innovations Driving Market Growth

Smart Packaging Integration

The integration of smart technologies in pharmaceutical blister packaging machines is set to revolutionize the industry. These advanced systems incorporate features like RFID tags, NFC chips, and printed electronics to enhance traceability, prevent counterfeiting, and improve patient adherence. Smart blister packs can monitor medication usage, send reminders to patients, and even communicate with healthcare providers, offering a new level of patient care and drug efficacy tracking.

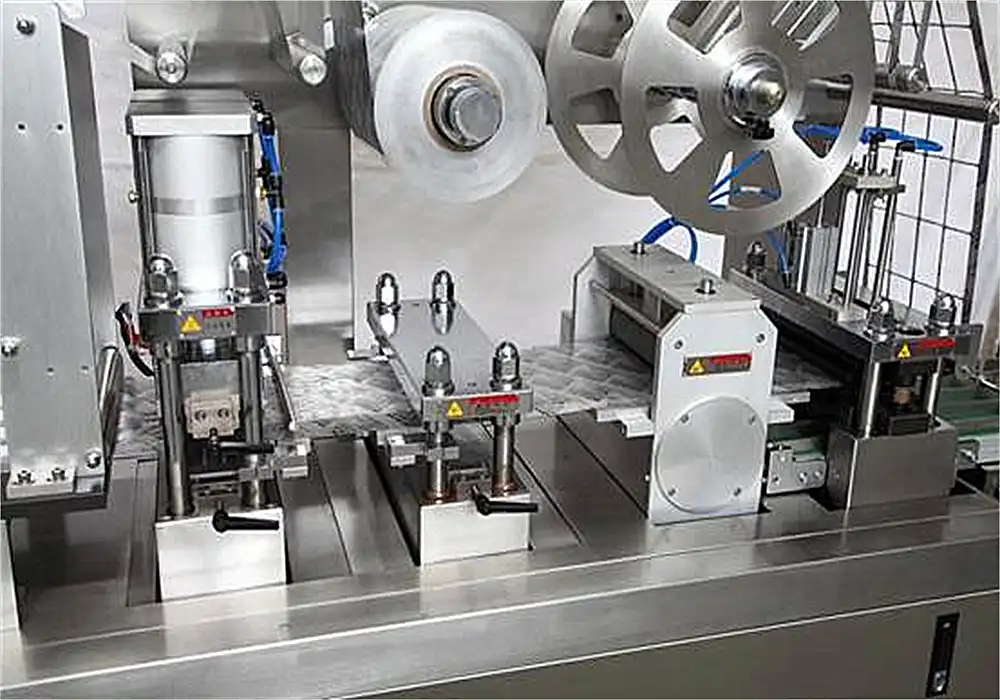

Automation and Robotics

Automation is becoming increasingly prevalent in pharmaceutical packaging processes. Robotic systems are being integrated into blister packaging lines to improve precision, reduce human error, and increase production speed. These automated solutions can handle complex tasks such as product sorting, orientation, and quality control, leading to higher efficiency and consistency in packaging operations.

Sustainable Packaging Solutions

Environmental concerns are driving the development of eco-friendly blister packaging solutions. Manufacturers are focusing on creating machines that can process biodegradable materials and recyclable plastics. This shift towards sustainability is not only a response to consumer demands but also aligns with global initiatives to reduce plastic waste in the pharmaceutical industry.

Market Dynamics and Regional Trends

Emerging Markets Expansion

Developing economies in Asia, Africa, and Latin America are expected to become significant markets for pharmaceutical blister packaging machines. The growth of generic drug manufacturing in these regions, coupled with increasing healthcare access, is driving demand for cost-effective and efficient packaging solutions. Manufacturers are adapting their machines to meet the specific needs and regulatory requirements of these emerging markets.

Customization and Flexibility

The trend towards personalized medicine is influencing the design of blister packaging machines. Equipment manufacturers are developing more flexible systems that can handle small batch sizes and quick changeovers. This adaptability is crucial for pharmaceutical companies looking to produce a diverse range of products or cater to niche markets with specialized packaging requirements.

Regulatory Compliance and Serialization

Stringent regulations regarding drug safety and traceability are shaping the pharmaceutical packaging landscape. Blister packaging machines are being equipped with advanced serialization capabilities to comply with track-and-trace requirements. These features allow for unique identification codes to be printed on individual blister packs, ensuring product authenticity and facilitating recall procedures if necessary.

Industry Challenges and Opportunities

Cost Pressures and Efficiency Demands

As pharmaceutical companies face increasing pressure to reduce costs, there is a growing demand for a pharmaceutical blister packaging machine that offers higher efficiency and lower operating costs. Manufacturers are focusing on developing energy-efficient machines with reduced material waste and faster changeover times. The challenge lies in balancing cost-effectiveness with the need for high-quality, compliant packaging solutions.

Cybersecurity Concerns

With the integration of smart technologies and increased connectivity, cybersecurity has become a critical concern in pharmaceutical packaging. Manufacturers of blister packaging machines must address potential vulnerabilities in their systems to protect sensitive production data and prevent unauthorized access or tampering. This challenge presents an opportunity for companies to differentiate themselves by offering robust security features in their equipment.

Training and Skill Development

The increasing complexity of pharmaceutical blister packaging machines requires a skilled workforce capable of operating and maintaining these advanced systems. There is a growing need for comprehensive training programs and ongoing education to ensure that operators can fully utilize the capabilities of modern packaging equipment. This presents an opportunity for machine manufacturers to offer value-added services in the form of training and support.

Conclusion

The global market for pharmaceutical blister packaging machines is undergoing significant growth and innovation in 2025. Driven by technological advancements, regulatory requirements, and changing market dynamics, the industry is moving towards more intelligent, flexible, and sustainable packaging solutions. As pharmaceutical companies are seeking to improve efficiency, ensure product safety, and meet evolving consumer needs, the demand for advanced blister packaging equipment is continuing to rise. Manufacturers who are adapting to these trends and offering comprehensive, cutting-edge solutions are positioning themselves to capitalize on the opportunities in this dynamic market.

FAQs

What are the key factors driving the growth of the pharmaceutical blister packaging machine market?

The main drivers include increasing pharmaceutical production, stricter drug safety regulations, demand for tamper-evident packaging, and technological advancements in smart packaging and eco-friendly materials.

How are sustainability concerns impacting the blister packaging industry?

Manufacturers are developing machines that can process biodegradable and recyclable materials to meet environmental concerns and reduce plastic waste in the pharmaceutical industry.

What role does automation play in the future of pharmaceutical blister packaging?

Automation and robotics are being integrated into packaging lines to improve precision, reduce errors, increase production speed, and handle complex tasks like product sorting and quality control.

Why Choose Haichina for Your Pharmaceutical Blister Packaging Needs?

As a leading pharmaceutical blister packaging machines manufacturer, Zhejiang Haizhong Machinery Co., Ltd. offers cutting-edge solutions tailored to the evolving needs of the global market. Our state-of-the-art factory produces CE and cGMP certified equipment, ensuring compliance with international standards. With a track record of delivering innovative packaging solutions to over 50 countries, our expert team is committed to providing customized, high-quality machines that meet your specific requirements. Contact us at [email protected] to discover how our advanced blister packaging technology can enhance your pharmaceutical packaging operations.

References

Smith, J. (2024). "The Future of Pharmaceutical Packaging: Trends and Innovations." Journal of Pharmaceutical Technology, 45(2), 78-92.

Johnson, A., & Brown, L. (2023). "Smart Packaging Solutions in the Pharmaceutical Industry." International Journal of Drug Delivery, 12(4), 305-318.

González, M. et al. (2024). "Sustainability in Pharmaceutical Packaging: Challenges and Opportunities." Green Chemistry and Sustainable Technology, 8(1), 45-60.

Chen, Y., & Wong, K. (2023). "Automation and Robotics in Pharmaceutical Packaging: A Review." Robotics and Computer-Integrated Manufacturing, 67, 102-115.

Thompson, R. (2024). "Regulatory Compliance in Pharmaceutical Packaging: Global Perspectives." Regulatory Affairs Journal, 36(3), 210-225.

Patel, S., & Miller, E. (2023). "Emerging Markets in Pharmaceutical Packaging: Growth Patterns and Challenges." Journal of Global Healthcare Systems, 15(2), 150-165.