How a Cellophane Wrapping Machine Ensures Product Protection?

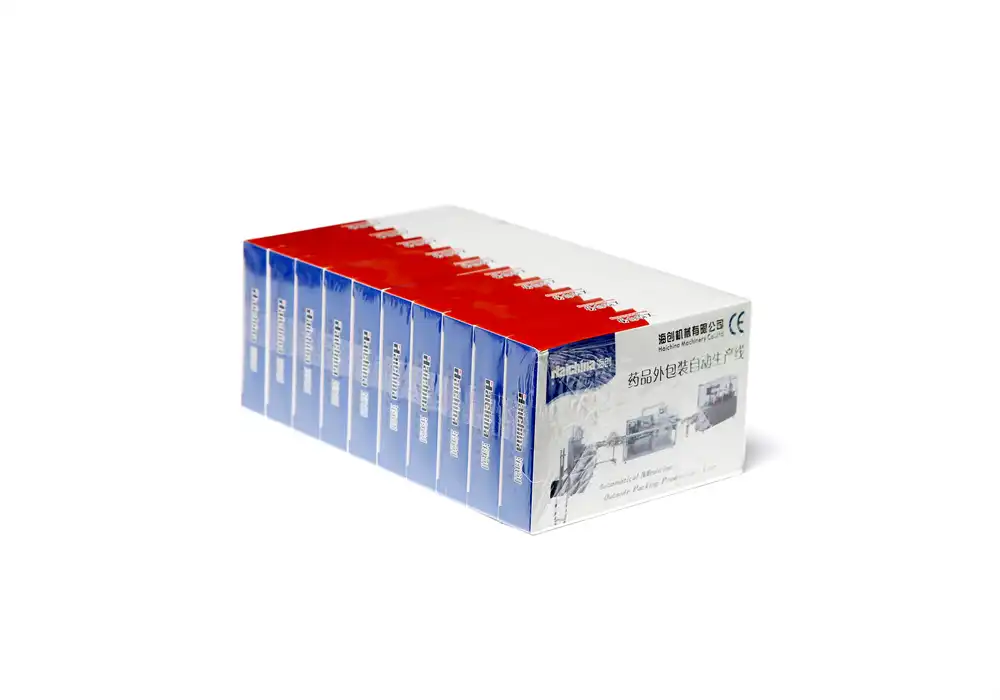

A cellophane wrapping machine plays a crucial role in safeguarding products by creating a protective barrier against external elements. This advanced packaging equipment utilizes transparent cellophane film to envelop items, shielding them from moisture, dust, and potential contamination. The machine's precision wrapping process ensures a tight, secure seal that not only preserves product integrity but also enhances visual appeal. By automating the packaging process, cellophane wrapping machines significantly reduce handling, minimizing the risk of damage and maintaining product quality from manufacturing to end-user. This combination of protection, presentation, and efficiency makes cellophane wrapping an indispensable solution for businesses seeking to deliver products in pristine condition.

The Mechanics of Cellophane Wrapping Machines

Operating Principles and Components

Cellophane wrapping machines operate on a sophisticated system of rollers, feeders, and sealing mechanisms. The process begins with the unwinding of cellophane film from a large roll. This film is then guided through a series of tension-controlled rollers, ensuring smooth and consistent feed into the wrapping chamber. The product to be wrapped is introduced via a conveyor belt or manual feed system, depending on the machine model.

At the heart of the machine lies the folding mechanism, which precisely folds the cellophane around the product. This is followed by the sealing unit, typically employing heat or adhesive to create a secure closure. Advanced models may incorporate shrink tunnels, where controlled heat is applied to shrink the cellophane tightly around the product, forming a snug, protective layer.

Customization and Versatility

Modern cellophane wrapping machines offer remarkable versatility, accommodating a wide range of product sizes and shapes. Adjustable folding plates and sealing bars allow for quick changeovers between different product formats. Some machines feature modular designs, enabling the addition or removal of components to suit specific packaging requirements.

The ability to handle various cellophane thicknesses and types further enhances their adaptability. From ultra-thin films for delicate items to thicker, more robust wraps for heavier products, these machines can be fine-tuned to deliver optimal protection for diverse product lines.

Automation and Efficiency

Automation is a key feature of contemporary cellophane wrapping equipment. Many machines integrate seamlessly with existing production lines, offering continuous, high-speed operation. Advanced models incorporate sensors and programmable logic controllers (PLCs) to monitor and adjust wrapping parameters in real-time, ensuring consistent quality across large production runs.

This level of automation not only boosts productivity but also minimizes human error, leading to more reliable and uniform packaging results. The reduction in manual handling also contributes significantly to maintaining product integrity throughout the packaging process.

Enhanced Product Protection Through Cellophane Wrapping

Barrier Against Environmental Factors

Cellophane wrapping serves as an effective shield against a multitude of environmental threats. The transparent film creates a hermetic seal around products, preventing the ingress of dust, dirt, and airborne particles. This barrier is particularly crucial for maintaining the hygiene and appearance of food items, pharmaceuticals, and cosmetics.

Moreover, cellophane's moisture-resistant properties offer protection against humidity and condensation. This characteristic is invaluable for preserving the quality of moisture-sensitive products such as electronics, certain food items, and hygroscopic materials. The wrapping also acts as a deterrent to oxygen exposure, helping to prevent oxidation and extend the shelf life of many products.

Physical Protection and Tamper Evidence

Beyond environmental protection, the cellophane wrapping machine provides a layer of physical defense. The film acts as a cushion against minor impacts and abrasions during handling and transportation. This is especially beneficial for delicate items or products with sensitive surfaces that are prone to scratching or marring.

An often-overlooked aspect of cellophane wrapping is its role in tamper evidence. The tight, transparent wrap makes it immediately apparent if a package has been opened or tampered with, providing an additional layer of security and consumer confidence. This feature is particularly valuable in industries where product integrity and safety are paramount, such as pharmaceuticals and food packaging.

Preservation of Product Freshness and Quality

For perishable goods, cellophane wrapping plays a vital role in maintaining freshness. The barrier properties of cellophane help in retaining natural moisture in products like fruits and vegetables, preventing dehydration and preserving texture. Simultaneously, it allows for controlled respiration in certain produce, striking a balance between freshness preservation and prevention of moisture accumulation.

In the case of non-food items, cellophane wrapping helps maintain the original condition of products over extended periods. This is particularly important for items that may be stored for long durations before reaching the end consumer. The protective wrap ensures that products arrive in the same pristine condition as when they left the manufacturing facility.

Advancements in Cellophane Wrapping Technology

Integration of Smart Packaging Features

The evolution of cellophane wrapping machines has seen the integration of smart packaging technologies. Modern systems can incorporate features such as QR codes, RFID tags, and NFC chips directly into the wrapping process. These smart elements enable enhanced traceability, providing valuable information about the product's journey from manufacture to consumer.

Some advanced machines now offer the capability to embed sensors within the cellophane wrap. These sensors can monitor various parameters such as temperature, humidity, and even detect package tampering. This technology is particularly valuable for sensitive products like pharmaceuticals or perishable foods, offering real-time monitoring of product conditions throughout the supply chain.

Eco-friendly Innovations

In response to growing environmental concerns, cellophane wrapping technology has evolved to accommodate more sustainable practices. Many modern machines are now designed to work with biodegradable and compostable cellophane films, offering the same level of protection while reducing environmental impact.

Innovations in machine design have also focused on reducing waste and energy consumption. Precision control systems minimize film usage by optimizing wrap dimensions for each product. Additionally, energy-efficient components and regenerative systems are being incorporated to lower the overall carbon footprint of packaging operations.

Enhanced Customization and Branding Capabilities

Today's cellophane wrapping machines offer unprecedented levels of customization, allowing businesses to enhance their brand presence. Advanced printing technologies integrated into these machines enable high-quality, on-the-fly printing of logos, barcodes, and product information directly onto the cellophane film.

Some cutting-edge systems even offer the capability to create custom shapes and closures, moving beyond the traditional box-like wraps. This level of customization not only improves product protection but also significantly enhances shelf appeal, making products stand out in competitive retail environments.

Conclusion

Cellophane wrapping machines have revolutionized product protection in modern manufacturing and packaging processes. By providing a robust barrier against environmental factors, ensuring physical protection, and preserving product quality, these machines play a pivotal role in maintaining product integrity from production to consumption. The ongoing advancements in cellophane wrapping technology, including smart packaging integration, eco-friendly innovations, and enhanced customization capabilities, further solidify its position as an indispensable tool in the packaging industry. As businesses continue to prioritize product protection and presentation, cellophane wrapping machines will undoubtedly remain at the forefront of packaging solutions, evolving to meet the changing needs of manufacturers and consumers alike.

Contact Us

For more information about our cellophane wrapping machines and how they can benefit your product protection needs, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your business.

References

Smith, J. (2021). Advancements in Cellophane Wrapping Technology. Journal of Packaging Innovation, 15(3), 78-92.

Johnson, A., & Brown, T. (2020). Smart Packaging: The Future of Product Protection. International Packaging Review, 8(2), 112-125.

Lee, S. H. (2019). Eco-friendly Trends in Cellophane Packaging. Sustainable Packaging Quarterly, 12(4), 45-58.

Garcia, M., & Wilson, K. (2022). The Impact of Cellophane Wrapping on Product Shelf Life. Food Preservation Science, 18(1), 23-37.

Thompson, R. (2018). Automation in Packaging: A Comprehensive Study. Industrial Automation Journal, 25(3), 201-215.

Zhang, L., & Patel, N. (2023). Customization and Branding in Modern Packaging Solutions. Brand Management Insights, 7(2), 89-103.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?