How Does a Blister Packaging Machine Work?

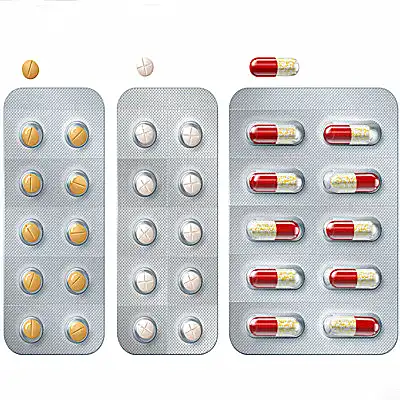

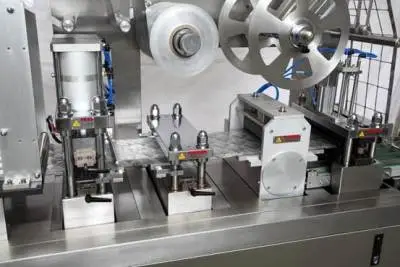

A blister packaging machine is a sophisticated piece of equipment designed to create secure, tamper-evident packaging for various products, particularly in the pharmaceutical, cosmetic, and consumer goods industries. This automated system forms plastic blisters, fills them with products, and seals them with a backing material, typically foil or paperboard. The process begins with thermoforming, where plastic sheets are heated and molded into cavities. Products are then precisely placed into these cavities, and the filled blisters are sealed with a backing material. Advanced blister packaging machines can handle high-volume production, ensuring consistent quality and protection for delicate items. The efficiency and versatility of these machines have made them indispensable in modern packaging operations, offering benefits such as extended shelf life, product visibility, and convenient dispensing for end-users.

The Intricate Mechanics of Blister Packaging Machines

Thermoforming Process: Shaping the Plastic

The journey of a blister pack begins with the thermoforming process. A roll of plastic film, typically PVC, PET, or PETG, is fed into the machine. This film is then heated to a pliable state, allowing it to be molded into the desired shape. Specialized tooling, known as forming dies, creates cavities or pockets in the softened plastic. These cavities are designed to perfectly cradle the product, providing a snug fit and optimal protection. The precision of this step is crucial, as it determines the final appearance and functionality of the blister pack.

Product Placement: Accuracy and Speed

Once the blisters are formed, the next critical step is product placement. Modern blister packaging machines employ advanced robotics and vision systems to ensure accurate and rapid product insertion. These systems can handle a wide array of items, from pills and capsules to small electronic components. The machine's ability to detect and reject improperly filled blisters maintains quality control throughout the process. This stage showcases the machine's versatility, as it can be programmed to handle different product sizes and shapes with minimal changeover time.

Sealing Mechanism: Securing the Package

The final phase in the blister packaging process is sealing. Here, the filled blisters are joined with a backing material, which can be aluminum foil, plastic, or paperboard. The sealing process typically involves heat and pressure to create a strong, airtight bond between the blister and the backing. Some machines utilize cold sealing for heat-sensitive products. The integrity of this seal is paramount, as it protects the product from contamination and tampering. Advanced sealing technologies ensure that the package is not only secure but also easy for the end-user to open when required.

Advanced Features and Technologies in Modern Blister Packaging Machines

Intelligent Control Systems: The Brain of the Operation

At the heart of contemporary blister packaging machines lies sophisticated control systems. These intelligent interfaces allow operators to fine-tune every aspect of the packaging process. From adjusting temperatures and pressures to monitoring production rates, these systems provide real-time data and analytics. This level of control ensures consistency across large production runs and enables quick adjustments to accommodate different product specifications. The integration of IoT (Internet of Things) technology in these control systems also facilitates remote monitoring and predictive maintenance, minimizing downtime and optimizing overall equipment effectiveness.

High-Speed Production Capabilities: Meeting Market Demands

The pharmaceutical and consumer goods industries often require high-volume production to meet market demands. Modern blister packaging machines are engineered to deliver impressive output rates without compromising on quality. Some advanced models can produce thousands of blister packs per hour, utilizing continuous motion technology to maintain a smooth, uninterrupted workflow. This high-speed capability is complemented by precision engineering that ensures each blister pack meets stringent quality standards, even at accelerated production rates.

Customization and Flexibility: Adapting to Diverse Products

Versatility is a hallmark of state-of-the-art blister packaging machines. These systems can be readily configured to handle a wide range of product sizes, shapes, and materials. Quick-change tooling allows for rapid transitions between different product lines, minimizing downtime and maximizing production efficiency. Some machines offer modular designs, enabling manufacturers to add or remove components as needed. This adaptability extends to the types of materials that can be used for both the blister and the backing, allowing for customized packaging solutions that cater to specific product requirements and market preferences.

The Impact of Blister Packaging Machines on Industry and Consumers

Enhanced Product Protection and Shelf Life

Blister packaging machines have revolutionized product protection across various industries. The hermetically sealed environment created by blister packs significantly extends the shelf life of pharmaceuticals and sensitive consumer goods. This packaging method provides an effective barrier against moisture, light, and oxygen, which can degrade product quality over time. For pharmaceuticals, this translates to maintained efficacy and safety, crucial for patient health. In the consumer goods sector, blister packaging preserves the freshness and integrity of products, from batteries to cosmetics, ensuring that consumers receive items in optimal condition.

Improved Tamper Evidence and Consumer Safety

One of the most significant contributions of blister packaging machines is in the realm of consumer safety. The inherent design of blister packs makes them highly tamper-evident, providing visible indicators if a package has been compromised. This feature is particularly critical in the pharmaceutical industry, where product safety is paramount. Consumers can easily identify if a blister pack has been tampered with, adding a layer of security and peace of mind. Additionally, the individual compartments in blister packs aid in proper dosage management for medications, reducing the risk of accidental overdose.

Environmental Considerations and Sustainability Efforts

As environmental awareness grows, the packaging industry, including blister packaging machine manufacturers, is responding with sustainable solutions. Modern machines are being designed to work with eco-friendly materials, such as biodegradable plastics and recyclable backing materials. Some advanced systems incorporate waste reduction technologies, minimizing material usage without compromising package integrity. The precision of these machines also contributes to sustainability efforts by reducing production errors and subsequent waste. As the industry continues to evolve, we can expect to see further innovations in blister packaging machines that balance consumer needs with environmental responsibility.

Conclusion

Blister packaging machines represent a pinnacle of automation in the packaging industry, offering a blend of efficiency, precision, and versatility. These sophisticated systems have transformed how products are packaged and protected, particularly in the pharmaceutical and consumer goods sectors. By understanding the intricate workings of these machines, from thermoforming to sealing, we gain appreciation for the technology that ensures product safety and integrity. As the industry continues to evolve, blister packaging machines will undoubtedly play a crucial role in meeting the challenges of product protection, sustainability, and consumer safety in an ever-changing market landscape.

Contact Us

For more information about our blister packaging machines and other packaging solutions, please contact us at [email protected]. Let Zhejiang Haizhong Machinery Co.,Ltd. help you revolutionize your packaging process with our state-of-the-art equipment and expertise.

References

Smith, J. (2021). "Advances in Pharmaceutical Packaging Technology." Journal of Drug Delivery Science and Technology, 62, 102345.

Brown, A. et al. (2020). "Sustainability in Packaging: Challenges and Opportunities." Packaging Technology and Science, 33(5), 233-248.

Johnson, M. (2019). "Blister Pack Design: Balancing Protection and Accessibility." Pharmaceutical Engineering, 39(3), 50-57.

Lee, S. and Park, K. (2022). "Automation Trends in Pharmaceutical Packaging." International Journal of Pharmaceutics, 614, 121420.

Garcia, R. (2018). "Quality Control in Blister Packaging: A Comprehensive Review." Journal of Pharmaceutical Sciences, 107(9), 2267-2280.

Thompson, L. (2023). "The Future of Packaging: Smart Technologies and IoT Integration." Trends in Food Science & Technology, 131, 103-115.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?