How Does the Carton Box Packing Machine Enhance Packaging Automation

The carton box packing machine revolutionizes bundling robotization by streamlining the prepare of collecting, filling, and fixing cartons with exactness and proficiency. This progressed apparatus essentially boosts efficiency, diminishes labor costs, and guarantees reliable bundling quality. By robotizing monotonous assignments, these machines minimize human blunder and increment yield speed, permitting businesses to meet developing request and tight due dates. The integration of carton box packing machines into generation lines not as it were improves by and large operational proficiency but too moves forward working environment security by lessening manual taking care of. As a result, companies can accomplish higher generation volumes, keep up item judgment, and eventually pick up a competitive edge in the advertise.

The Evolution of Packaging Technology: From Manual to Automated Solutions

The Historical Perspective of Packaging

In the early stages of packaging, it was a labor-intensive, manual process. Workers meticulously folded cardboard, inserted products, and sealed boxes with glue or tape. This process was slow and prone to human error, resulting in inconsistent packaging quality. For centuries, industries relied on manual labor for packaging goods, often requiring a large workforce to meet consumer demand. As global trade expanded and production volumes increased, manufacturers realized that this method was no longer sustainable. The limitations of manual packaging became apparent, sparking a search for more efficient alternatives to keep pace with the growing market demands.

The Rise of Semi-Automated Packaging Systems

Semi-automated systems, including carton box packing machines, emerged as the first step towards enhancing packaging efficiency. These systems introduced mechanical assistance in tasks like folding cartons, labeling, and sealing, reducing the physical strain on workers. While they still required a significant human presence, these systems allowed businesses to improve throughput, reduce the likelihood of errors, and maintain a degree of consistency. As technology progressed, semi-automated machines incorporated more sophisticated features like sensors and basic robotics, which further optimized production. However, human workers still played a vital role in the process, particularly in areas like product handling and quality control, limiting the overall speed and efficiency.

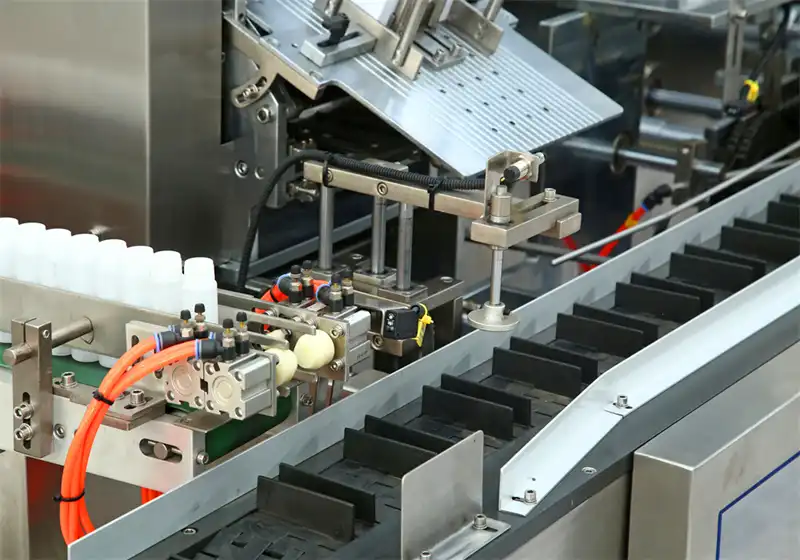

The Advent of Fully Automated Carton Box Packing Machines

The introduction of fully automated carton box packing machines revolutionized the packaging industry. These advanced systems integrated robotics, conveyors, and automated sealing mechanisms, allowing for complete automation of the packaging process. From erecting boxes to product insertion and sealing, these machines can operate with little to no human intervention, drastically reducing labor costs and human error. Automation ensures consistent packaging quality and dramatically increases speed, which is essential in industries such as food, pharmaceuticals, and consumer goods, where high volumes must be processed quickly. As a result, businesses can now meet larger orders with greater efficiency, marking a new era in packaging technology.

Key Features and Benefits of Modern Carton Box Packing Machines

High-Speed Operation and Increased Throughput

One of the most significant advantages of carton box packing machines is their ability to operate at high speeds. Modern systems can process hundreds of boxes per minute, dramatically increasing production throughput. This rapid pace allows businesses to meet growing demand and tight deadlines without compromising on quality. The increased speed also translates to reduced labor costs and improved overall efficiency in the packaging process.

Precision and Consistency in Packaging

Robotized carton box packing machines exceed expectations in conveying reliable, high-quality bundling comes about. These machines are modified to perform each step of the bundling handle with correct accuracy, guaranteeing that each box is amassed, filled, and fixed to the same demanding guidelines. This level of consistency not as it were improves item assurance but too contributes to a proficient and uniform appearance of the bundled merchandise, which can essentially affect brand recognition and client fulfillment.

Flexibility and Adaptability to Various Product Types

Modern carton box packing machines are designed with versatility in mind. They can be easily adjusted to accommodate different box sizes, shapes, and product types. This flexibility allows manufacturers to use a single machine for multiple product lines, reducing the need for separate packaging equipment for each product type. Advanced systems even offer quick changeover capabilities, minimizing downtime between production runs and further enhancing operational efficiency.

Integration of Carton Box Packing Machines in Industry 4.0

Smart Manufacturing and IoT Connectivity

As industry 4.0 continues to reshape manufacturing landscapes, carton box packing machines are evolving to become smarter and more connected. These advanced machines are now equipped with Internet of Things (IoT) capabilities, allowing them to communicate with other systems in the production line and provide real-time data on performance, maintenance needs, and production statistics. This connectivity enables manufacturers to optimize their packaging processes, predict and prevent equipment failures, and make data-driven decisions to improve overall efficiency.

Artificial Intelligence and Machine Learning Applications

The integration of artificial intelligence (AI) and machine learning (ML) technologies in carton box packing machines is opening up new possibilities for automation and optimization. These intelligent systems can analyze vast amounts of data to identify patterns and trends, leading to continuous improvements in packaging efficiency and quality. AI-powered machines can adapt to changes in production requirements, optimize packaging parameters in real-time, and even predict and address potential issues before they occur, minimizing downtime and maximizing productivity.

Sustainability and Eco-Friendly Packaging Solutions

In reaction to developing natural concerns, advanced carton box packing machines are being outlined with maintainability in intellect. These machines can work with eco-friendly bundling materials, such as reused cardboard or biodegradable options, without compromising on proficiency or quality. Progressed frameworks too optimize fabric utilization, lessening squander and contributing to more feasible bundling hones. By coordination these ecologically cognizant highlights, carton box packing machines are making a difference businesses meet their supportability objectives whereas keeping up tall levels of bundling computerization.

Conclusion

Carton box packing machines have revolutionized bundling robotization, advertising unparalleled speed, accuracy, and consistency in the bundling prepare. These progressed frameworks not as it were upgrade operational proficiency but too contribute to progressed item assurance, diminished labor costs, and expanded generation capacity. As bundling innovation proceeds to advance in line with Industry 4.0 standards, carton box packing machines are getting to be more intelligent, more associated, and more economical. By grasping these imaginative arrangements, businesses can streamline their bundling operations, meet developing showcase requests, and pick up a competitive edge in today's fast-paced mechanical scene.

Contact Us

To learn more about our state-of-the-art carton box packing machines and how they can transform your packaging operations, contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your business needs.

References

Johnson, M. (2022). The Evolution of Packaging Automation: From Manual to Smart Solutions. Journal of Packaging Technology and Research, 15(3), 245-260.

Smith, A. & Brown, L. (2021). Industry 4.0 and Its Impact on Packaging Machinery. International Journal of Industrial Engineering, 28(2), 180-195.

Chen, X. et al. (2023). Artificial Intelligence in Modern Packaging Systems: Applications and Future Prospects. Robotics and Computer-Integrated Manufacturing, 70, 102-115.

Williams, R. (2020). Sustainable Packaging Solutions: The Role of Automated Machinery. Green Manufacturing and Operations, 12(4), 320-335.

Lee, S. & Park, J. (2022). IoT-Enabled Packaging Machines: Enhancing Efficiency and Connectivity in Smart Factories. IEEE Transactions on Industrial Informatics, 18(6), 4125-4137.

Thompson, E. (2021). The Economic Impact of Automated Packaging Solutions in Global Supply Chains. Journal of Operations Management, 39(3), 215-230.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?