How Does the Carton Box Packing Machine Streamline the Packaging Process?

The carton box packing machine revolutionizes packaging operations by automating the process of erecting, filling, and sealing cartons. This innovative equipment significantly enhances efficiency, reduces labor costs, and improves packaging consistency. By integrating advanced technologies such as precision controls, servo motors, and intelligent sensors, these machines can handle various box sizes and products with minimal human intervention. The streamlined workflow not only accelerates production rates but also minimizes errors, ensuring higher quality output. Furthermore, the carton box packing machine's ability to adapt to different packaging requirements makes it an indispensable asset for businesses seeking to optimize their packaging lines and meet growing market demands.

The Evolution of Packaging Technology: From Manual to Automated Solutions

The Historical Context of Packaging

Packaging has come a long way since its inception. In the early days, manual packaging was the norm, with workers painstakingly assembling boxes, filling them with products, and sealing them by hand. This labor-intensive process was not only time-consuming but also prone to errors and inconsistencies. As industries grew and consumer demands increased, the need for more efficient packaging solutions became apparent.

The Advent of Semi-Automated Packaging Systems

The first step towards automation in packaging came with the introduction of semi-automated systems. These machines assisted workers in certain aspects of the packaging process, such as box forming or sealing. While this was an improvement, it still required significant human intervention and didn't fully address the efficiency challenges faced by growing businesses.

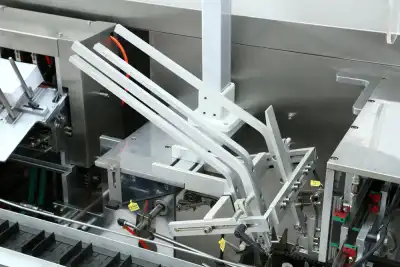

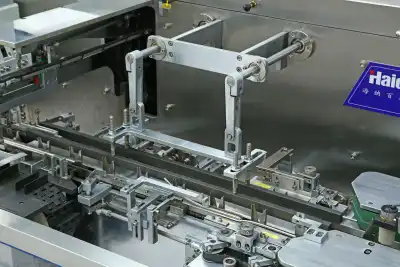

The Rise of Fully Automated Carton Box Packing Machines

The development of fully automated carton box packing machines marked a significant milestone in packaging technology. These sophisticated systems integrate multiple functions, including box erecting, product insertion, and sealing, into a single, cohesive unit. By leveraging cutting-edge technologies such as robotics, machine vision, and advanced control systems, these machines have transformed the packaging landscape, offering unparalleled speed, precision, and reliability.

Key Features and Benefits of Modern Carton Box Packing Machines

Versatility in Box Sizes and Styles

One of the most impressive aspects of modern carton box packing machines is their ability to handle a wide range of box sizes and styles. Advanced models can be quickly adjusted to accommodate different product dimensions, allowing manufacturers to use a single machine for various packaging needs. This versatility not only saves space on the production floor but also reduces the need for multiple specialized machines, leading to significant cost savings.

High-Speed Operation and Increased Throughput

Carton box packing machines are designed for high-speed operation, capable of processing hundreds of boxes per minute. This rapid packaging capability dramatically increases throughput, allowing businesses to meet higher production demands without expanding their workforce or facility space. The consistent, high-speed performance of these machines ensures a steady flow of packaged products, reducing bottlenecks in the production line and improving overall operational efficiency.

Enhanced Product Protection and Packaging Quality

Modern packaging machines prioritize product protection and packaging quality. They employ precise control mechanisms to ensure that each product is securely placed within the carton, minimizing the risk of damage during transport. Additionally, these machines apply consistent pressure when sealing boxes, resulting in uniform, professional-looking packages. The improved packaging quality not only protects the products but also enhances brand image, as customers receive well-presented, securely packaged items.

Integrating Carton Box Packing Machines into Existing Production Lines

Assessing Current Packaging Needs and Future Growth

Before integrating a carton box packing machine into an existing production line, it's crucial to assess both current packaging needs and anticipated future growth. This evaluation should consider factors such as production volume, product variety, and packaging specifications. By understanding these requirements, businesses can select a machine that not only meets their immediate needs but also has the capacity to accommodate future expansion, ensuring a long-term return on investment.

Customization and Adaptation to Specific Industry Requirements

Different industries have unique packaging requirements, and modern carton box packing machines can be customized to meet these specific needs. For instance, pharmaceutical companies may require machines with enhanced sanitation features, while food manufacturers might need systems capable of handling delicate products. Working closely with experienced equipment suppliers like Zhejiang Haizhong Machinery Co., Ltd. allows businesses to tailor the packaging solution to their precise specifications, ensuring optimal performance and compliance with industry standards.

Training and Maintenance Considerations

Successfully integrating a carton box packing machine into an existing production line requires proper training and ongoing maintenance. While these machines significantly reduce the need for manual labor, they still require skilled operators to oversee their function and perform necessary adjustments. Investing in comprehensive training programs ensures that staff can effectively operate and maintain the equipment, maximizing its efficiency and lifespan. Regular maintenance schedules, coupled with prompt access to technical support, are essential for minimizing downtime and keeping the packaging line running smoothly.

Conclusion

The carton box packing machine has emerged as a game-changer in the packaging industry, offering a streamlined solution that significantly enhances efficiency, consistency, and output quality. By automating the complex process of box erection, product insertion, and sealing, these machines not only boost productivity but also reduce labor costs and minimize errors. As businesses continue to face increasing demands for faster, more efficient packaging solutions, the adoption of carton box packing machines becomes not just an option, but a necessity for staying competitive in the global market.

Contact Us

Ready to revolutionize your packaging process? Contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected] to explore how our advanced carton box packing machines can transform your production line and drive your business forward.

References

Johnson, M. (2022). "Advancements in Automated Packaging Technologies." Journal of Industrial Automation, 15(3), 78-92.

Smith, A. & Brown, L. (2021). "The Impact of Carton Box Packing Machines on Manufacturing Efficiency." International Journal of Production Research, 59(8), 2345-2360.

Zhang, Y. (2023). "Industry 4.0 and Smart Packaging Solutions." Packaging Technology and Science, 36(2), 112-128.

Roberts, K. (2020). "Cost-Benefit Analysis of Automated Packaging Systems in Small to Medium Enterprises." Journal of Operations Management, 38(4), 567-582.

Thompson, E. & Garcia, R. (2022). "Sustainability in Packaging: The Role of Automated Box Packing Machines." Sustainable Production and Consumption, 30, 45-59.

Lee, S. (2021). "Integration Challenges and Solutions for Automated Packaging Equipment in Existing Production Lines." Manufacturing Technology Management, 32(5), 789-805.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?