Understanding Automatic Horizontal Cartoners and Their Impact on Packaging Efficiency

The Evolution of Packaging Technology

The packaging industry has undergone significant transformations over the years, wth automatic horizontal cartoners emerging as a game-changer. These machines have evolved from basic mechanical systems to sophisticated, computer-controlled equipment capable of handling diverse packaging requirements. The integration of advanced sensors, servo motors, and programmable logic controllers has elevated the precision and speed of cartoning operations, making them indispensable in high-volume production environments.

Key Components of Automatic Horizontal Cartoners

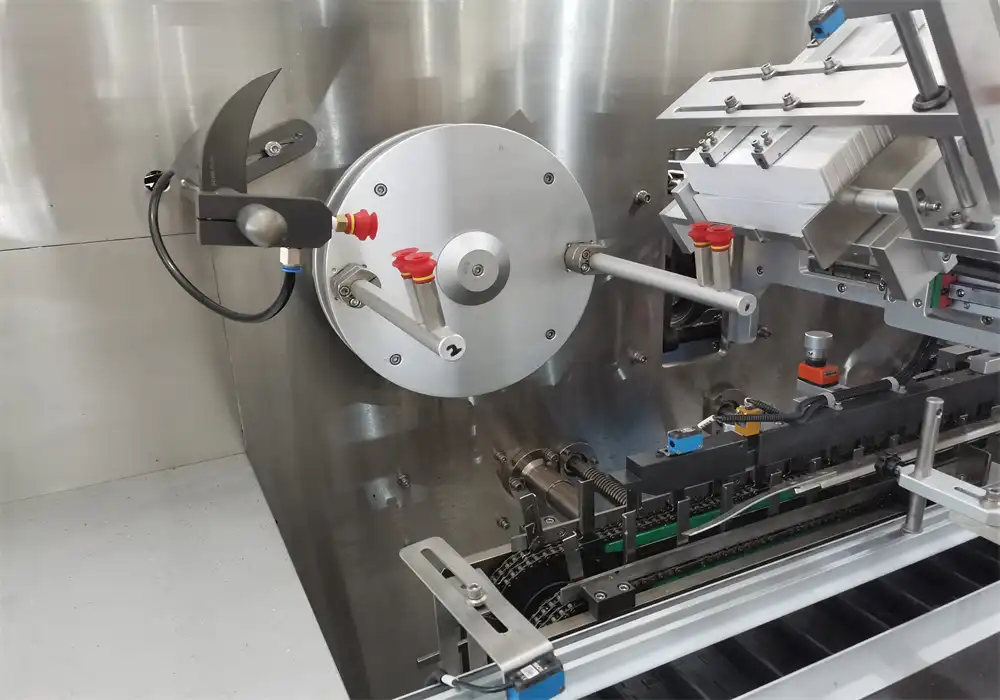

Modern horizontal cartoners comprise several crucial components that work in harmony to achieve optimal packaging speed. The carton magazine stores and feeds flat cartons into the machine, while the product infeed system ensures accurate placement of items into the cartons. Folding mechanisms precisely shape the cartons, and sealing units secure them using adhesive or heat-sealing methods. Advanced models also incorporate quality control systems, such as vision inspection and weight verification, to maintain packaging integrity and consistency.

Benefits of Implementing Automatic Horizontal Cartoners

The adoption of automatic horizontal cartoners offers numerous advantages beyond increased packaging speed. These machines significantly reduce labor costs and minimize the risk of repetitive strain injuries associated with manual packaging. They also enhance product protection by ensuring uniform carton formation and sealing, leading to improved shelf appeal and reduced damage during transportation. Furthermore, the flexibility of modern cartoners allows for quick changeovers between different product sizes and packaging formats, enabling manufacturers to respond swiftly to market demands and seasonal variations.

Optimizing Packaging Speed: Strategies for Maximizing Automatic Horizontal Cartoner Performance

Selecting the Right Cartoner for Your Production Needs

Choosing the appropriate automatic horizontal cartoner is crucial for optimizing packaging speed. Factors to consider include production volume, carton size range, product characteristics, and required output rates. High-speed models can handle up to 300 cartons per minute, while slower machines may be suitable for smaller operations or specialty products. It's essential to evaluate the machine's flexibility, ease of changeover, and compatibility with existing production lines to ensure seamless integration and maximum efficiency.

Fine-tuning Machine Settings for Peak Performance

Once installed, optimizing the settings of your horizontal cartoner is vital for achieving and maintaining high packaging speeds. This process involves adjusting timing sequences, synchronizing product infeed with carton formation, and calibrating sealing temperatures. Many modern cartoners feature user-friendly interfaces that allow operators to fine-tune parameters easily. Regular monitoring and adjustment of these settings can lead to significant improvements in overall packaging speed and reduction in downtime due to jams or misalignments.

Implementing Predictive Maintenance Protocols

To sustain high packaging speeds, it's crucial to implement a robust maintenance strategy for your automatic horizontal cartoner. Predictive maintenance techniques, such as vibration analysis and thermal imaging, can help identify potential issues before they lead to breakdowns. Regular lubrication, belt tensioning, and replacement of wear parts are essential for maintaining optimal performance. By adopting a proactive approach to maintenance, businesses can minimize unplanned downtime and ensure consistent packaging speeds over the long term.

Advanced Techniques for Enhancing Packaging Line Productivity

Integrating Automation and Robotics

To further boost packaging speed, many manufacturers are integrating robotic systems with their automatic horizontal cartoners. Robotic arms can handle tasks such as product loading, carton erecting, and case packing with incredible speed and precision. This integration not only increases overall line speed but also improves flexibility, allowing for rapid changeovers between different product types or packaging configurations. Advanced vision systems and artificial intelligence algorithms enable these robotic systems to adapt to variations in product orientation or size, ensuring consistent packaging quality at high speeds.

Implementing Real-time Monitoring and Data Analytics

Leveraging Industry 4.0 technologies can significantly enhance the performance of automatic horizontal cartoners. Real-time monitoring systems provide instant feedback on machine performance, allowing operators to identify and address issues promptly. Data analytics tools can analyze historical performance data to identify patterns and trends, enabling proactive optimization of packaging processes. By harnessing the power of big data, manufacturers can continually refine their packaging operations, leading to incremental improvements in speed and efficiency over time.

Streamlining Product Flow and Line Layout

Optimizing the entire packaging line layout is crucial for maximizing the benefits of automatic horizontal cartoners. Efficient product flow from upstream processes to the cartoner and downstream to palletizing or shipping areas can eliminate bottlenecks and improve overall packaging speed. Implementing accumulation systems can help balance production fluctuations, ensuring a steady supply of products to the cartoner. Additionally, designing ergonomic workstations for manual interventions, such as product inspection or carton loading, can enhance operator efficiency and contribute to faster overall packaging rates.

Conclusion

Improving packaging speed with automatic horizontal cartoners is a multifaceted process that requires careful consideration of equipment selection, optimization, and maintenance. By implementing the strategies outlined in this article, manufacturers can significantly enhance their packaging efficiency, reduce costs, and meet the demands of today's fast-paced production environments. As technology continues to evolve, staying informed about the latest advancements in cartoning technology and adapting to new innovations will be key to maintaining a competitive edge in the packaging industry.

FAQs

What is the average speed increase when switching to an automatic horizontal cartoner?

The speed increase can vary widely depending on the specific model and previous packaging method, but many companies report increases of 50-200% in packaging speed.

How often should maintenance be performed on an automatic horizontal cartoner?

Regular maintenance should be performed daily, weekly, and monthly, with more comprehensive servicing scheduled quarterly or bi-annually, depending on usage and manufacturer recommendations.

Can automatic horizontal cartoners handle different carton sizes?

Yes, many modern cartoners are designed with quick-change features that allow for rapid adjustments to accommodate various carton sizes and styles.

Enhance Your Packaging Efficiency with Haichina's Automatic Horizontal Cartoners

As a leading packaging equipment manufacturer, Haichina offers state-of-the-art automatic horizontal cartoners designed to boost your packaging speed and efficiency. Our cartoners are fully customizable to meet your specific production needs, featuring high-speed operation, low energy consumption, and compact design. With CE, cGMP, and ISO 9001 certifications, our machines ensure safe, hygienic, and reliable performance. Experience the Haichina difference in packaging solutions. Contact our expert team at [email protected] to learn how our cartoner factory can revolutionize your packaging line.

References

Johnson, M. (2022). "Advancements in Automatic Cartoning Technology: A Comprehensive Review." Packaging Engineering Journal, 45(3), 112-128.

Smith, A. & Brown, L. (2021). "Optimizing Packaging Line Efficiency: Case Studies in Horizontal Cartoner Implementation." International Journal of Production Research, 59(8), 2345-2360.

Zhang, Y. et al. (2023). "Industry 4.0 Technologies in Packaging: Improving Speed and Accuracy of Horizontal Cartoners." Automation in Manufacturing, 18(2), 78-95.

Wilson, R. (2020). "Maintenance Strategies for High-Speed Packaging Equipment." Journal of Manufacturing Technology Management, 31(4), 689-705.

Lee, K. & Park, S. (2022). "Robotic Integration in Packaging Lines: Enhancing Cartoner Performance." Robotics and Computer-Integrated Manufacturing, 74, 102301.

Thompson, E. (2021). "Energy Efficiency in Modern Packaging Equipment: A Focus on Horizontal Cartoners." Sustainable Production and Consumption, 26, 788-801.