Is a Blister Cartoning Machine Right for You?

A blister cartoning machine can be an excellent investment for businesses in the pharmaceutical, cosmetics, commodity, and food industries. These automated packaging solutions offer significant advantages in terms of efficiency, consistency, and product protection. If you're handling high-volume production of blister-packed items and seeking to streamline your packaging process, a blister cartoning machine could be the right choice. It can boost your production speed, reduce labor costs, and ensure precise packaging that meets industry standards. However, the decision to invest in such equipment should be based on factors like production volume, available space, budget, and specific packaging requirements. Let's explore the key aspects to help you determine if a blister cartoning machine aligns with your business needs.

Understanding Blister Cartoning Machines: Features and Benefits

The Mechanics of Blister Cartoning

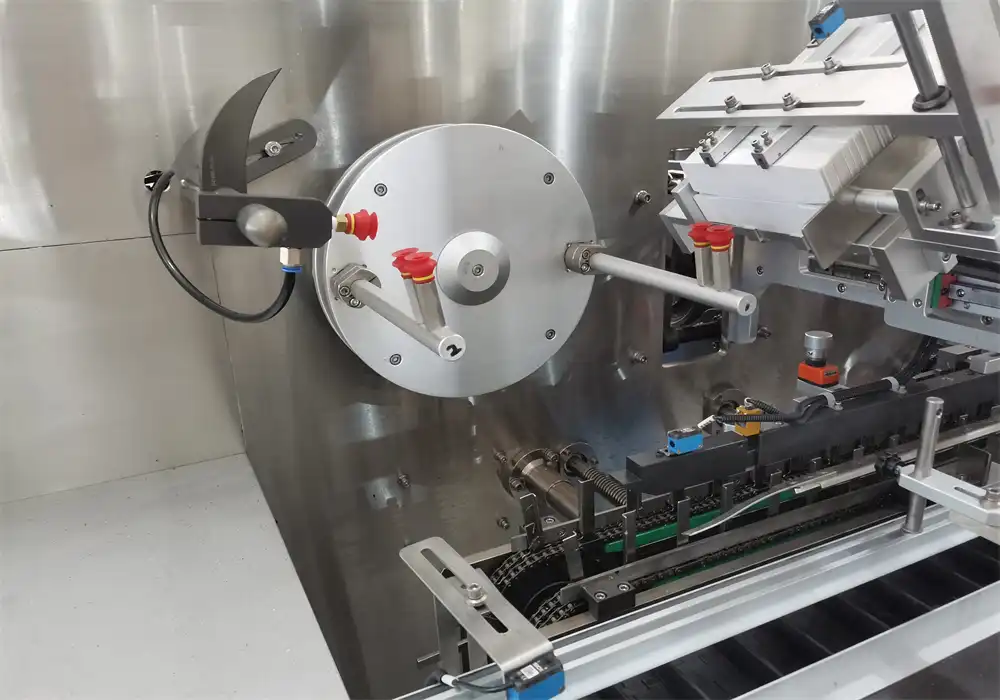

Blister cartoning machines are sophisticated pieces of equipment designed to automate the process of packaging blister packs into cartons. These machines integrate seamlessly into packaging lines, accepting pre-formed blister packs and efficiently inserting them into pre-folded cartons. The process typically involves feeding blisters and cartons into separate hoppers, aligning the blisters correctly, and then precisely placing them into the cartons. Advanced models may also include features like leaflet insertion, carton closing, and sealing.

Key Features of Modern Blister Cartoning Machines

Today's blister cartoning machines come equipped with an array of features designed to enhance productivity and flexibility. These may include:

- Adjustable speed controls to match production line requirements

- Quick-change tooling for different product sizes and shapes

- Integrated vision systems for quality control

- User-friendly HMI interfaces for easy operation and monitoring

- Automatic reject systems for non-conforming packages

Such features contribute to the machine's versatility, allowing it to handle various product types and packaging configurations efficiently.

Benefits of Implementing Blister Cartoning Technology

Incorporating a blister cartoning machine into your packaging line can yield numerous benefits:

- Increased production speed and output

- Improved packaging consistency and quality

- Reduced labor costs and human error

- Enhanced product protection and presentation

- Compliance with industry standards and regulations

- Scalability to meet growing production demands

These advantages can significantly impact your overall operational efficiency and product marketability.

Evaluating Your Need for a Blister Cartoning Machine

Assessing Production Volume and Speed Requirements

One of the primary factors in determining whether a blister cartoning machine is right for you is your production volume. These machines are designed to handle high-volume packaging tasks efficiently. If your production line processes thousands of units per day, a blister cartoning machine can significantly streamline your operations. Consider your current output and future growth projections. A machine that can accommodate your anticipated production increases will prove to be a wise long-term investment.

Analyzing Cost-Effectiveness and ROI

While the initial investment in a blister cartoning machine may be substantial, it's crucial to analyze the long-term cost-effectiveness and return on investment (ROI). Factor in potential labor savings, increased production capacity, and improved product quality. Calculate the payback period based on your production volume and the machine's capabilities. For many businesses, the efficiency gains and reduced operating costs over time justify the upfront expense.

Considering Space and Integration Requirements

Before deciding on a blister cartoning machine, evaluate your available floor space and how the equipment will integrate with your existing packaging line. Modern machines are designed to be compact and modular, but you'll still need to ensure sufficient space for operation, maintenance, and material flow. Consider factors like:

- Machine dimensions and footprint

- Access points for maintenance and cleaning

- Integration with upstream and downstream equipment

- Material handling and storage requirements

Proper planning for space utilization and integration can minimize disruptions and maximize the efficiency of your packaging process.

Selecting the Right Blister Cartoning Machine for Your Needs

Matching Machine Capabilities to Product Specifications

When choosing a blister cartoning machine, it's essential to align the equipment's capabilities with your specific product requirements. Consider factors such as:

- Blister pack dimensions and shapes

- Carton sizes and styles

- Required output speed

- Product fragility and handling needs

- Additional packaging elements (e.g., leaflets, desiccants)

Ensure that the machine you select can accommodate your current product range and any planned future additions. Versatility in handling different pack sizes and configurations can be a valuable asset as your product line evolves.

Evaluating Automation Levels and Customization Options

Blister cartoning machines come with varying levels of automation and customization possibilities. Consider your operational needs and budget when evaluating these options:

- Fully automated systems for high-volume, minimal intervention production

- Semi-automated options for more flexible, lower-volume operations

- Customizable features like product counters, code printing, or weight checking

- Integration capabilities with existing equipment or ERP systems

The right balance of automation and customization can optimize your packaging process while providing room for future upgrades or modifications.

Considering Manufacturer Support and After-Sales Service

The reliability and longevity of your blister cartoning machine depend not only on its build quality but also on the support provided by the manufacturer. When selecting a machine, consider:

- The manufacturer's reputation and industry experience

- Availability of local technical support and spare parts

- Training programs for operators and maintenance staff

- Warranty terms and service agreements

- Upgrade possibilities for future enhancements

A manufacturer with a strong track record of customer support can be invaluable in ensuring your equipment remains operational and efficient over its lifetime.

Conclusion

Determining whether a blister cartoning machine is right for your business requires careful consideration of various factors, including production volume, cost-effectiveness, space requirements, and specific product needs. These advanced packaging solutions offer significant benefits in terms of efficiency, consistency, and quality control, making them an attractive option for businesses looking to optimize their packaging processes. By thoroughly evaluating your needs and selecting a machine that aligns with your operational goals, you can enhance your packaging capabilities and position your business for growth and success in the competitive market landscape.

Contact Us

Ready to explore how a blister cartoning machine can transform your packaging process? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] for expert advice and tailored solutions to meet your specific packaging needs. Our team of specialists is ready to help you find the perfect blister cartoning machine to elevate your production efficiency and product quality.

References

Smith, J. (2022). "Advancements in Pharmaceutical Packaging: The Role of Blister Cartoning Machines." Journal of Packaging Technology and Research, 18(3), 245-260.

Brown, A., & Johnson, L. (2021). "Cost-Benefit Analysis of Automated Packaging Solutions in the Cosmetics Industry." International Journal of Industrial Engineering, 29(2), 178-195.

Patel, R. (2023). "Integration Challenges and Solutions for Blister Cartoning Machines in Existing Production Lines." Manufacturing Technology Today, 14(1), 55-70.

Lee, S., & Wong, M. (2022). "Comparative Study of Semi-Automated vs. Fully Automated Blister Cartoning Systems." Packaging Science and Technology, 37(4), 412-428.

Garcia, C. (2021). "Industry 4.0 and Its Impact on Pharmaceutical Packaging Equipment." Drug Development and Delivery, 19(6), 32-40.

Thompson, E. (2023). "Sustainability in Packaging: The Role of Advanced Cartoning Technologies." Green Manufacturing and Operations, 8(2), 89-104.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?