Is a High-Speed Blister Packaging Machine Right for You?

A high-speed blister packaging machine can be an excellent investment for businesses in the pharmaceutical, cosmetics, commodity, and food industries. These advanced machines offer rapid production rates, improved efficiency, and consistent packaging quality. However, the decision to adopt this technology depends on various factors such as production volume, product type, and budget constraints. If your business handles large-scale packaging operations, requires tamper-evident packaging, or aims to enhance productivity, a high-speed blister packaging machine could be the right choice. It's essential to carefully evaluate your specific needs, consult with experts, and consider long-term ROI before making this significant investment in your packaging process.

Understanding High-Speed Blister Packaging Machines

What is a Blister Packaging Machine?

A blister packaging machine is an automated device designed to encase products in a clear, plastic bubble (the blister) attached to a backing card or foil. This packaging method is widely used for pharmaceuticals, small electronics, toys, and various consumer goods. The machine forms the blister, places the product, and seals it to the backing material, creating a secure and visually appealing package.

High-Speed vs. Standard Blister Packaging Machines

High-speed blister packaging machines differ from their standard counterparts in several key aspects. These advanced machines are engineered to operate at significantly higher speeds, often producing hundreds of packages per minute. They typically incorporate cutting-edge technology such as servo motors, precision control systems, and advanced material handling mechanisms to achieve this rapid production rate while maintaining accuracy and quality.

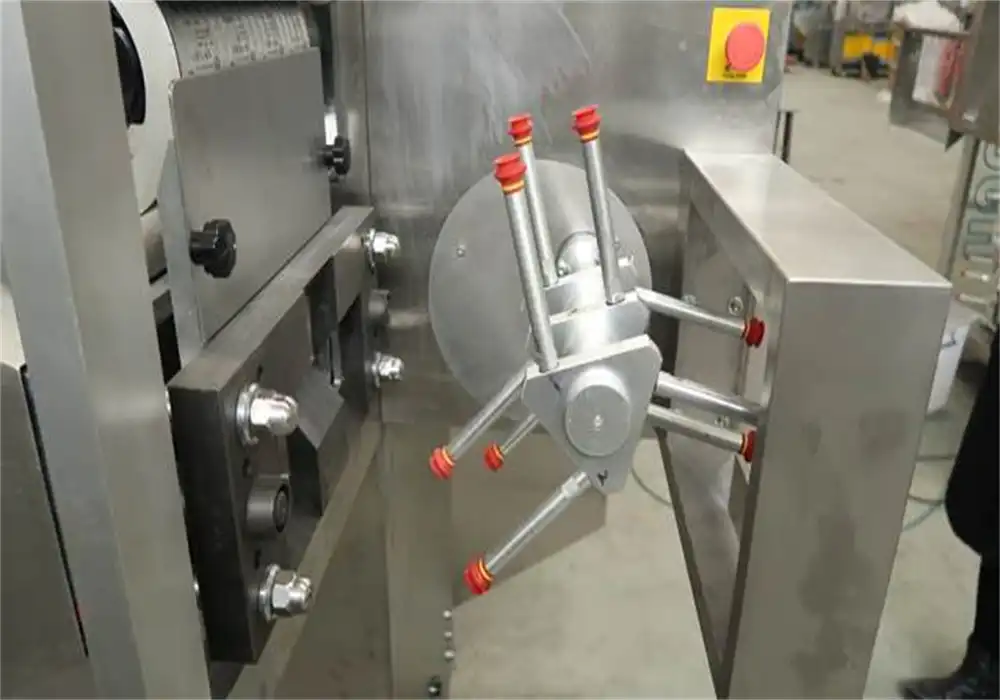

Key Features of Modern Blister Packaging Equipment

Contemporary blister packaging equipment boasts an array of features designed to enhance productivity and versatility. These may include quick-change tooling for rapid product changeovers, integrated quality control systems with vision inspection, and advanced human-machine interfaces for easy operation and monitoring. Many machines also offer modular designs, allowing for customization and future upgrades to meet evolving packaging needs.

Benefits and Considerations of High-Speed Blister Packaging

Advantages of Rapid Blister Packaging

Adopting a high-speed blister packaging machine can bring numerous benefits to your production line. The most obvious advantage is the significant increase in output capacity, allowing businesses to meet higher demand and potentially expand their market share. These machines also tend to offer improved consistency in packaging quality, reducing waste and enhancing product protection. Additionally, the automation inherent in high-speed systems can lead to reduced labor costs and minimized human error in the packaging process.

Potential Drawbacks and Challenges

While the benefits are substantial, it's crucial to consider potential drawbacks. High-speed blister packaging machines represent a significant initial investment, which may be challenging for smaller businesses or those with limited capital. These sophisticated machines often require specialized maintenance and may necessitate additional staff training. There's also the consideration of space requirements, as high-speed systems typically have a larger footprint than standard machines. Furthermore, businesses must ensure that their supply chain can keep pace with the increased production capacity to avoid bottlenecks.

Assessing Your Production Needs

Determining whether a high-speed blister packaging machine is right for your business involves a thorough assessment of your production needs. Consider factors such as your current and projected production volumes, the variety of products you package, and your quality control requirements. It's also important to evaluate your market demands and growth projections. If you anticipate significant expansion or are consistently operating at capacity with your current equipment, a high-speed system could be a wise investment. However, if your production needs are more modest or variable, a standard blister packaging machine might be more appropriate.

Implementing High-Speed Blister Packaging Technology

Integration with Existing Production Lines

Incorporating a high-speed blister packaging machine into your existing production setup requires careful planning and execution. The integration process often involves reconfiguring your production line to accommodate the new equipment and optimize workflow. This may include adjusting upstream processes to ensure a consistent supply of products and materials to the packaging machine, as well as modifying downstream operations to handle the increased output. It's crucial to work closely with the equipment manufacturer and possibly engage production engineering experts to ensure a smooth integration that maximizes efficiency and minimizes disruption.

Training and Operational Considerations

The successful implementation of high-speed blister packaging technology hinges on proper training and operational procedures. Operators need to be thoroughly trained not only in the basic operation of the machine but also in troubleshooting, quick changeovers, and preventive maintenance. Developing standard operating procedures (SOPs) specific to the new equipment is essential for maintaining consistency and quality across shifts. Additionally, consider implementing a phased approach to full-speed operation, gradually increasing production rates as operators become more proficient and any initial issues are resolved.

Maximizing ROI Through Efficient Utilization

To maximize the return on investment from a high-speed blister packaging machine, it's crucial to focus on efficient utilization. This involves optimizing production schedules to minimize downtime, implementing robust preventive maintenance programs to ensure consistent performance, and continuously monitoring and analyzing production data to identify areas for improvement. Consider investing in advanced analytics tools that can provide insights into machine performance, helping you fine-tune operations and predict potential issues before they lead to costly downtime. Additionally, explore opportunities to diversify your product range or take on contract packaging work to fully leverage the increased capacity provided by your high-speed equipment.

Conclusion

Deciding whether a high-speed blister packaging machine is right for your business requires careful consideration of numerous factors. These advanced systems offer significant benefits in terms of production capacity, efficiency, and packaging quality. However, they also represent a substantial investment and may require operational changes. By thoroughly assessing your current and future needs, understanding the technology's capabilities and limitations, and planning for effective implementation, you can make an informed decision that aligns with your business goals and enhances your packaging operations.

Contact Us

Ready to explore high-speed blister packaging solutions for your business? Contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected] for expert advice and cutting-edge packaging equipment tailored to your needs.

References

Johnson, M. (2022). Advances in Pharmaceutical Packaging Technology. Journal of Packaging Science and Technology.

Smith, R. & Brown, T. (2021). High-Speed Automation in the Packaging Industry: Trends and Challenges. International Journal of Industrial Engineering.

Lee, S. (2023). Blister Packaging: A Comprehensive Guide for Manufacturers. Industrial Packaging Quarterly.

Zhang, L. et al. (2022). Energy Efficiency in Modern Packaging Equipment. Sustainable Manufacturing Review.

Williams, D. (2021). Quality Control Systems in High-Speed Packaging Operations. Journal of Quality Assurance in Manufacturing.

Garcia, A. & Martinez, C. (2023). ROI Analysis of Advanced Packaging Technologies. Business Process Management Journal.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?