Material Selection and Design Optimization

Choosing the Right Materials

Selecting appropriate materials for blister packaging is crucial to ensuring drug stability, safety, and protection throughout its shelf life. Pharmaceutical companies need to carefully evaluate properties such as moisture barrier effectiveness, light protection, and chemical inertness when choosing materials for both the blister cavity and the lidding film. Commonly used materials include PVC, PVDC, COC, and aluminum foil, each providing specific benefits tailored to different drug formulations and packaging demands, helping maintain drug efficacy and compliance with regulatory standards.

Optimizing Blister Design

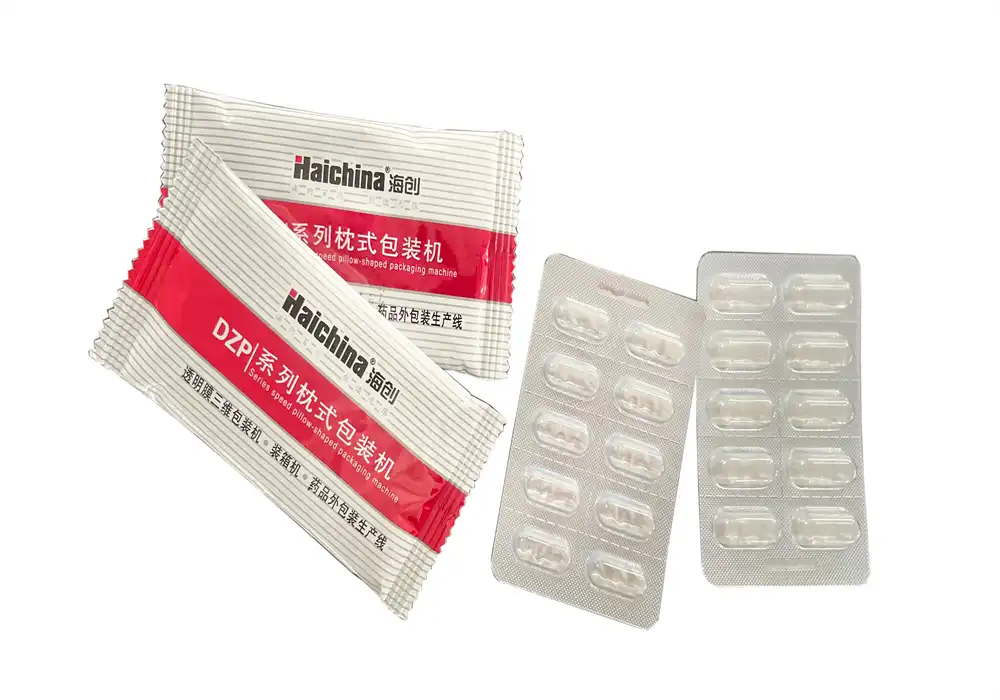

The design of blister packaging in the blister packaging machine is essential for protecting the product while also enhancing patient usability. Key factors like cavity size, shape, and depth should be meticulously planned to fit a variety of pill sizes and shapes while reducing excess headspace. Designs must also promote easy and safe pill removal for patients, especially those with limited dexterity, while incorporating child-resistant features where necessary. Innovative designs like calendar blisters or unit-dose packaging improve patient adherence and help reduce medication errors effectively.

Enhancing Barrier Properties

For drugs sensitive to moisture or oxygen, improving the barrier properties of blister packaging is vital to maintain product stability and extend shelf life. This improvement can be accomplished through multi-layer films, advanced high-barrier polymers, or specialized coatings designed to block environmental factors. Incorporating advanced technologies such as desiccant-integrated films or oxygen scavengers further protects the medication. Packaging engineers must carefully balance these enhanced barrier capabilities with cost efficiency and practical manufacturing considerations to optimize overall package performance.

Regulatory Compliance and Quality Assurance

Meeting Regulatory Standards

Compliance with regulatory standards is non-negotiable in pharmaceutical packaging. Blister packaging must adhere to guidelines set by regulatory bodies such as the FDA, EMA, and WHO. This includes requirements for material safety, stability testing, and labeling. Manufacturers must ensure their blister packaging processes and materials meet these standards, often necessitating rigorous documentation and testing protocols.

Implementing Quality Control Measures

Quality control is critical in pharmaceutical blister packaging machine operations to ensure product integrity and patient safety. This involves implementing robust inspection systems to detect defects such as seal integrity issues, foreign particles, or missing tablets. Advanced vision systems and leak detection technologies can be integrated into the packaging line to enhance quality assurance. Regular audits and validation of packaging processes are also essential to maintain consistent quality standards.

Ensuring Traceability and Anti-Counterfeiting

In an era of increasing drug counterfeiting, implementing traceability and anti-counterfeiting measures in blister packaging is crucial. This may involve the use of serialization, unique identifiers, or tamper-evident features. Advanced technologies such as RFID tags or QR codes can be incorporated into the packaging design to enable track-and-trace capabilities throughout the supply chain. These measures not only combat counterfeiting but also enhance recall management and supply chain visibility.

Advanced Blister Packaging Machines and Technologies

Selecting the Right Blister Packaging Machine

Choosing an appropriate blister packaging machine is critical for efficient and high-quality production. Modern blister packaging machines offer a range of features, including high-speed operation, flexibility for different blister formats, and integration with downstream processes such as cartoning. When selecting a machine, factors such as production volume, required changeover times, and compatibility with various packaging materials must be considered. Advanced machines may also offer features like servo-driven systems for precise control and energy efficiency.

Implementing Automation and Industry 4.0 Technologies

The integration of automation and Industry 4.0 technologies in blister packaging processes can significantly enhance efficiency and quality control. This may include the implementation of robotics for material handling, IoT sensors for real-time monitoring of machine performance, and data analytics for predictive maintenance. Advanced control systems can enable seamless integration of blister packaging machines with other equipment in the production line, optimizing overall efficiency and reducing downtime.

Embracing Sustainable Packaging Solutions

As sustainability becomes increasingly important in the pharmaceutical industry, blister packaging machines and processes must adapt to support eco-friendly initiatives. This may involve the use of recyclable or biodegradable materials, optimizing packaging designs to reduce material usage, or implementing energy-efficient technologies in packaging machinery. Some advanced blister packaging machines now offer features specifically designed to support sustainable packaging goals, such as the ability to process plant-based polymers or reduce waste during production.

Conclusion

Effective blister packaging in pharmaceutical use requires a multifaceted approach, considering material selection, design optimization, regulatory compliance, and advanced packaging technologies. By carefully evaluating these key considerations, pharmaceutical companies can ensure their products are well-protected, compliant with regulations, and efficiently produced. As the industry continues to evolve, staying informed about the latest advancements in blister packaging machines and materials will be crucial for maintaining a competitive edge and meeting the ever-increasing demands of the pharmaceutical market.

Contact Us

For more information on our advanced blister packaging solutions and how we can help optimize your pharmaceutical packaging processes, please contact us at [email protected]. Our team of experts is ready to assist you in implementing cutting-edge blister packaging technologies tailored to your specific needs.