Machine Vision for Blister Pack Inspection

Machine vision for blister pack inspection revolutionizes quality control in pharmaceutical packaging. this advanced technology integrates high-resolution cameras, sophisticated algorithms, and artificial intelligence to detect defects in blister packs with unparalleled accuracy. by scrutinizing each pack for issues like missing tablets, seal integrity, and proper filling, machine vision systems ensure that only flawless products reach consumers. this not only enhances patient safety but also significantly reduces waste and improves operational efficiency. as blister packaging machinery evolves, incorporating machine vision becomes crucial for manufacturers aiming to maintain the highest standards in an increasingly competitive market.

The Evolution of Blister Packaging Technology

Traditional Blister Packaging Methods

Blister packaging began as a revolutionary method for securing products, particularly in the pharmaceutical and consumer goods industries. Early blister machine packing systems were semi-automated at best, relying heavily on manual labor for inspection, feeding, and quality checks. These machines mainly focused on forming the plastic cavities and heat-sealing them with lidding foil. While effective for their time, they were limited in throughput, prone to variability, and required significant human oversight. As production demands grew, the shortcomings of traditional methods highlighted the need for more advanced, integrated solutions.

Advancements in Blister Packaging Equipment

The evolution of blister machine packing accelerated with the introduction of modern engineering and digital control systems. Today's machines feature high-precision thermoforming and cold-forming technologies, allowing for more complex and tailored blister designs. Enhanced servo-driven filling systems and intelligent temperature regulation for sealing have drastically improved consistency and efficiency. These updates enable packaging lines to work with a broad range of materials, including recyclable films and multi-layer laminates, without compromising speed or quality. These innovations have transformed blister packaging machines into flexible, high-performance tools suited for modern manufacturing environments.

Integration of Automation in Packaging Lines

The integration of automation into blister packaging lines has dramatically enhanced productivity and accuracy. Modern high-speed blister packing machines now include synchronized modules for forming, filling, sealing, perforating, and cartoning—all in a single, continuous process. This level of automation minimizes human error, reduces downtime, and ensures consistent quality across production batches. Furthermore, automated blister packaging systems can be easily integrated with upstream and downstream processes, including material handling and secondary packaging. These advances laid the groundwork for the next major innovation: the integration of real-time machine vision systems for advanced quality control.

The Role of Machine Vision in Blister Pack Inspection

Fundamentals of Machine Vision Technology

Machine vision technology in blister pack inspection involves sophisticated imaging systems coupled with advanced algorithms. These systems capture high-resolution images of each blister pack as it moves through the production line. The core components typically include high-speed cameras, specialized lighting, and powerful image processing software. This technology can detect anomalies that are imperceptible to the human eye, making it an invaluable tool in quality assurance.

Key Inspection Parameters in Blister Packaging

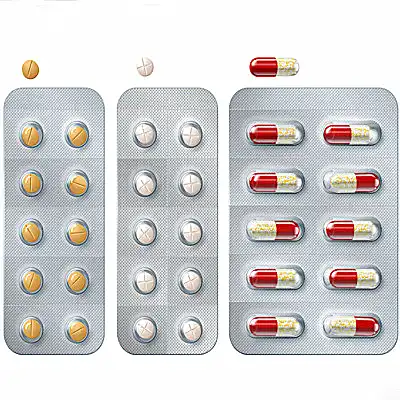

Machine vision systems in blister packaging machinery are programmed to inspect various critical parameters. These include checking for the presence and correct number of tablets or capsules, ensuring proper sealing of the blisters, verifying the integrity of the foil backing, and detecting any foreign particles or contaminants. Additionally, these systems can inspect print quality on the packaging, ensuring that all necessary information is clear and legible.

Benefits of Implementing Machine Vision in Packaging Lines

The implementation of machine vision in blister packaging equipment offers numerous benefits. It significantly enhances quality control by providing 100% inspection of all packages, drastically reducing the risk of defective products reaching the market. This technology also increases production efficiency by identifying issues in real-time, allowing for immediate corrective actions. Furthermore, it provides valuable data for process improvement and regulatory compliance, making it an essential component in modern pharmaceutical packaging operations.

Future Trends in Blister Pack Inspection Technology

Artificial Intelligence and Machine Learning Integration

The future of blister pack inspection lies in the integration of artificial intelligence (AI) and machine learning (ML) with existing machine vision systems. These technologies will enable inspection systems to become more adaptive and intelligent. AI-powered systems can learn from historical data, continuously improving their ability to detect defects and anomalies. This evolution will lead to even more accurate and efficient inspection processes, further enhancing the capabilities of blister packaging machinery.

Enhanced 3D Imaging Capabilities

Advancements in 3D imaging technology are set to revolutionize blister pack inspection. Unlike traditional 2D imaging, 3D vision systems can provide a more comprehensive view of the package, allowing for inspection of depth, volume, and surface texture. This technology will be particularly beneficial in detecting subtle deformations in blister cavities or identifying issues with seal integrity that may not be visible in 2D images, especially when integrated into a high speed blister packing machine.

Integration with Industry 4.0 and Smart Manufacturing

The future of blister packaging equipment will see deeper integration with Industry 4.0 principles and smart manufacturing concepts. Machine vision systems will become part of a larger, interconnected network of devices and systems. This integration will allow for real-time data sharing, predictive maintenance, and more efficient production planning. As a result, manufacturers will be able to achieve higher levels of automation, flexibility, and quality control in their blister packaging operations.

Conclusion

Machine Vision for Blister Pack Inspection represents a significant leap forward in pharmaceutical packaging technology. By incorporating advanced imaging and AI-driven analysis into blister packaging machinery, manufacturers can ensure unprecedented levels of quality control and efficiency. As the technology continues to evolve, we can expect even more sophisticated inspection capabilities, further enhancing the safety and reliability of blister-packed products. For companies looking to stay competitive in the pharmaceutical packaging industry, embracing these technological advancements is not just beneficial, but essential.

Contact Us

To learn more about our cutting-edge blister packaging equipment and machine vision solutions, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Let us help you elevate your packaging process to new heights of quality and efficiency.

References

Johnson, M. (2022). Advancements in Pharmaceutical Packaging Inspection. Journal of Packaging Technology and Research, 15(3), 245-260.

Smith, A., & Brown, B. (2021). Machine Vision Systems in Modern Manufacturing. Industrial Automation Quarterly, 42(2), 112-128.

Garcia, C. et al. (2023). AI-Driven Quality Control in Pharmaceutical Packaging. Artificial Intelligence in Industry, 7(1), 78-95.

Thompson, R. (2020). The Evolution of Blister Packaging Technology. Pharmaceutical Engineering Review, 33(4), 302-318.

Lee, S., & Wong, T. (2022). 3D Imaging Applications in Packaging Inspection. Journal of Visual Inspection Technologies, 18(2), 156-172.

Anderson, K. (2023). Industry 4.0 and Its Impact on Pharmaceutical Manufacturing. Smart Factory Journal, 9(3), 210-225.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?