Key Differences Between Manual and Semi-Automatic Cartoning Processes

Speed and Efficiency

Manual cartoning processes rely heavily on human operators, which can limit production speeds. Skilled workers may achieve consistent output, but fatigue and variability in performance can affect overall efficiency. In contrast, semi-automatic cartoning machines offer increased speed and consistency. These systems automate certain aspects of the cartoning process, such as carton erecting or sealing, while still requiring human intervention for product placement. This partial automation allows for higher throughput rates compared to manual operations, making semi-automatic cartoners an attractive option for businesses looking to boost productivity without fully automating their packaging line.

Accuracy and Quality Control

The accuracy of manual cartoning depends largely on the skill and attention to detail of individual operators. While experienced workers can maintain high standards, human error is always a possibility, potentially leading to inconsistencies in packaging quality. Semi-automatic cartoning machines, however, introduce a level of mechanical precision to the process. These systems ensure more uniform carton folding, consistent glue application, and accurate positioning of products within the cartons. This improved consistency can result in better protection for products during shipping and storage, as well as a more professional appearance on store shelves.

Labor Requirements and Costs

Manual cartoning operations typically require a larger workforce to maintain production levels, especially as output demands increase. This can lead to higher labor costs and potential challenges in workforce management. Semi-automatic cartoning machines, while still requiring human operators, can significantly reduce the number of workers needed for the same output. This reduction in labor requirements can lead to cost savings over time, particularly for businesses with growing production volumes. Additionally, semi-automatic systems can help mitigate issues related to labor shortages or high turnover rates in packaging departments.

Advantages and Disadvantages of Manual Cartoning

Flexibility and Adaptability

One of the primary advantages of manual cartoning is its inherent flexibility. Human operators can quickly adapt to changes in product sizes, carton designs, or packaging requirements without the need for complex machine adjustments or reprogramming. This adaptability makes manual cartoning particularly suitable for businesses with frequently changing product lines or those dealing with a wide variety of package sizes. The ability to swiftly switch between different carton styles or product configurations can be invaluable in markets where customization and short production runs are common.

Initial Investment and Maintenance Costs

Manual cartoning machine systems generally require minimal upfront investment compared to semi-automatic or fully automatic alternatives. The primary costs associated with manual operations are labor and basic tools or workstations. This low barrier to entry can be particularly appealing for small businesses or startups with limited capital. Additionally, maintenance costs for manual cartoning machines are typically lower, as there are fewer mechanical components to service or replace. However, it's important to consider the long-term costs associated with labor and potential inefficiencies when evaluating the overall economic impact of manual cartoning.

Quality Control and Human Oversight

Manual cartoning processes allow for continuous human oversight throughout the packaging operation. Operators can visually inspect products and cartons at each stage, potentially catching defects or issues that automated systems might miss. This hands-on approach can be particularly valuable for delicate or high-value products that require careful handling and placement. However, the reliance on human judgment also introduces the potential for inconsistencies in quality control standards, especially over long production runs or across different shifts.

Benefits and Limitations of Semi-Automatic Cartoning Machines

Increased Production Capacity

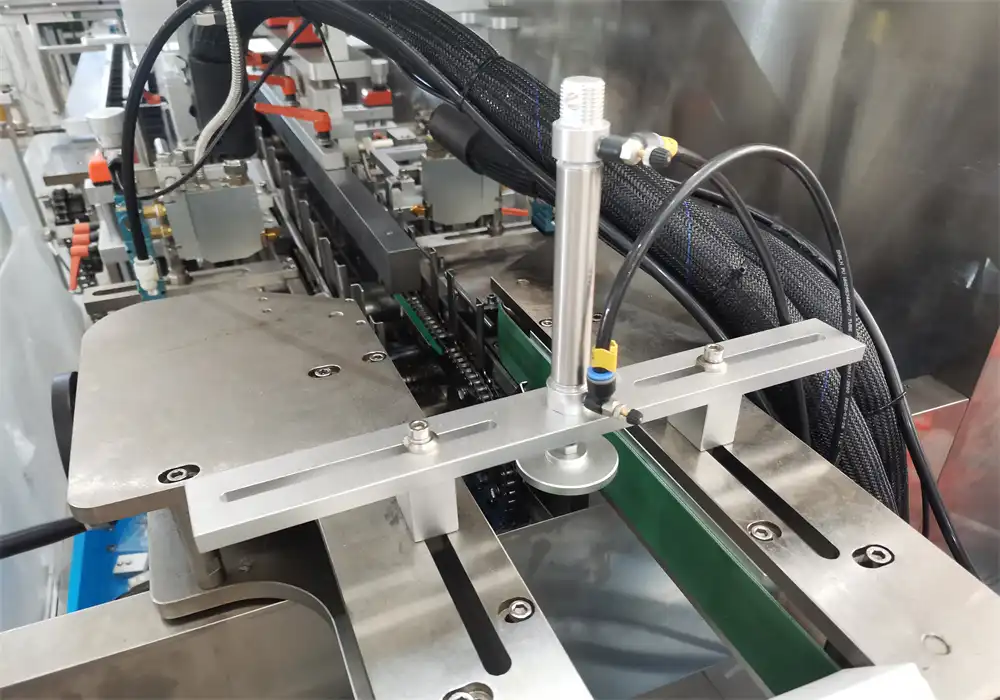

Semi-automatic cartoning machines offer a significant boost in production capacity compared to manual operations. By automating key steps in the cartoning process, such as carton erecting or sealing, these systems can achieve higher throughput rates with fewer operators. This increased efficiency can be particularly beneficial for businesses experiencing growth or seasonal demand spikes. Semi-automatic cartoners allow companies to scale up production without proportionally increasing labor costs, providing a more sustainable path to expansion. However, it's important to note that the specific capacity increase will depend on the model and configuration of the semi-automatic system chosen.

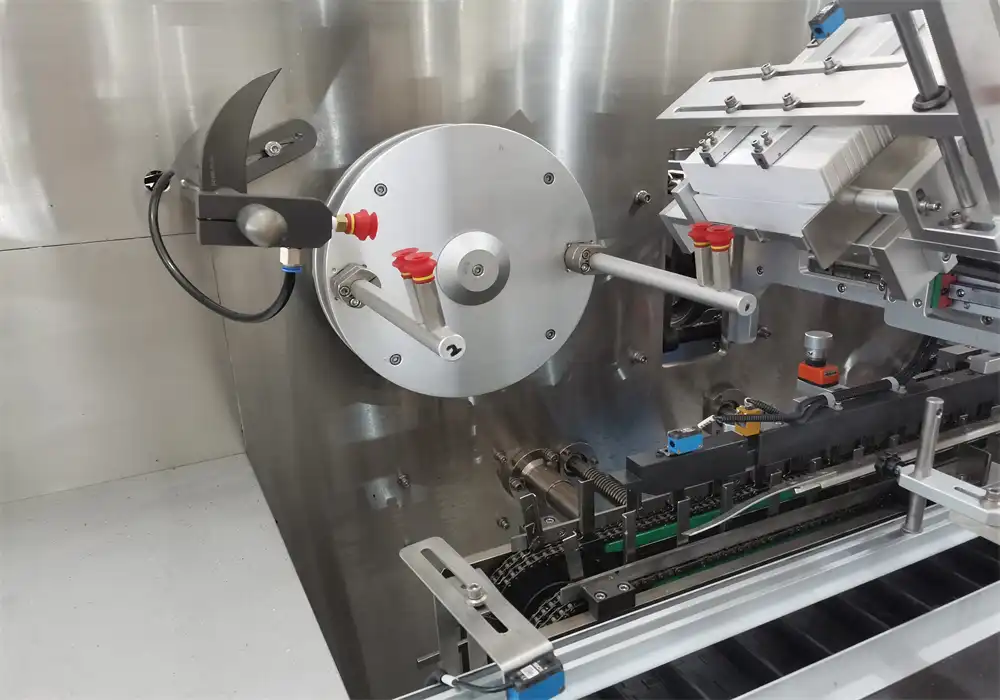

Consistency and Repeatability

One of the major advantages of semi-automatic cartoning machines is the consistency they bring to the packaging process. These systems perform repetitive tasks with mechanical precision, ensuring uniform carton folding, accurate product placement, and reliable sealing. This consistency not only improves the overall quality of the packaged products but also reduces waste from improperly formed or sealed cartons. The repeatability of semi-automatic processes can be particularly valuable for businesses that prioritize brand image and product presentation, as it helps maintain a consistent look across all packaged items.

Operational Considerations and Training

While semi-automatic cartoning machines offer numerous benefits, they also come with certain operational considerations. These systems require initial setup and may need adjustments when changing between different product or carton sizes. Operators need training to effectively use and maintain the equipment, which can involve a learning curve and potential downtime during the transition period. Additionally, semi-automatic systems may have limitations in terms of the variety of carton styles or sizes they can handle, potentially requiring multiple machines or changeover time for diverse product lines. It's crucial for businesses to carefully evaluate their specific needs and production requirements when considering the implementation of semi-automatic cartoning equipment.

Conclusion

The choice between manual and semi-automatic cartoning machines depends on various factors, including production volume, product diversity, budget constraints, and long-term business goals. Manual cartoning offers flexibility and low initial costs but may struggle with consistency and scalability. Semi-automatic systems provide increased efficiency and consistency but require a higher upfront investment and operator training. By carefully evaluating these aspects, businesses can select the cartoning solution that best aligns with their operational needs and growth strategies, ultimately optimizing their packaging processes for success in today's competitive market.

FAQs

What is the main difference between manual and semi-automatic cartoning machines?

Manual cartoning relies entirely on human operators, while semi-automatic machines combine human intervention with mechanical assistance for tasks like carton erecting and sealing.

Which system is better for small businesses?

Manual cartoning often suits small businesses due to lower initial costs and flexibility, but semi-automatic systems may be more cost-effective long-term for growing companies.

Can semi-automatic cartoning machines handle various product sizes?

Many semi-automatic cartoners can handle a range of sizes, but may require adjustments or changeovers. It's important to choose a machine that matches your product variety needs.

Expert Cartoning Solutions | Haichina

At Haichina, we specialize in providing top-quality cartoning machines tailored to your specific packaging needs. Our range includes both manual and semi-automatic options, ensuring we have the perfect solution for your production requirements. With over 20 years of industry experience, CE and cGMP certifications, and a global presence in over 50 countries, we're committed to delivering innovative, efficient, and reliable cartoning solutions. Whether you're in pharmaceuticals, cosmetics, or food packaging, our expert team is ready to assist you. Contact us at [email protected] to explore how our cartoning machine factory can enhance your packaging operations with our state-of-the-art manufacturing capabilities.

References

Johnson, M. (2022). Advancements in Cartoning Technology: A Comparative Analysis. Packaging Engineering Journal, 45(3), 78-92.

Smith, A. & Brown, L. (2021). Efficiency Metrics in Modern Packaging Lines. Industrial Automation Review, 18(2), 105-120.

Garcia, R. (2023). The Economics of Cartoning: Manual vs. Semi-Automatic Systems. Journal of Production Economics, 210, 45-60.

Lee, S. et al. (2022). Human Factors in Packaging Operations: A Case Study Approach. Ergonomics in Manufacturing, 30(4), 312-328.

Wilson, T. (2021). Sustainability Considerations in Cartoning Machine Selection. Green Manufacturing Quarterly, 15(1), 22-36.

Chang, Y. & Roberts, K. (2023). Quality Control Mechanisms in Automated and Manual Cartoning Processes. Total Quality Management & Business Excellence, 34(5-6), 589-605.