Mastering Cartoning: A Comprehensive Guide to Packaging Efficiency

Cartoning is a crucial aspect of packaging efficiency that can significantly impact production lines and overall business success. This comprehensive guide delves into the intricacies of cartoning, exploring how automated solutions like automatic cartoning machines can revolutionize packaging processes. We'll examine the latest technologies, best practices, and key considerations for implementing efficient cartoning systems. Whether you're in the pharmaceutical, cosmetics, or food industry, understanding the nuances of cartoning will help you optimize your packaging operations, reduce costs, and enhance product presentation. Join us as we unpack the world of cartoning and discover how to master this essential component of modern packaging.

The Evolution of Cartoning Technology

From Manual to Automated: A Historical Perspective

The journey of cartoning technology has been nothing short of remarkable. In the early days of packaging, manual cartoning was the norm, with workers painstakingly folding and filling cartons by hand. This labor-intensive process was not only time-consuming but also prone to errors and inconsistencies. As industries grew and demand increased, the need for more efficient methods became apparent.

The mid-20th century saw the advent of semi-automatic cartoning machines, which partially mechanized the process. These machines could form cartons and assist in filling, but still required significant human intervention. It wasn't until the latter part of the century that fully automatic cartoning machines emerged, revolutionizing the packaging industry.

The Rise of Automatic Cartoning Machines

Automatic cartoning machines represent a quantum leap in packaging technology. These sophisticated devices can handle the entire cartoning process with minimal human oversight. From carton erection to product insertion and sealing, automatic cartoners perform each step with precision and speed that far surpasses manual methods.

Modern cartoning equipment incorporates advanced features such as servo motors for precise control, vision systems for quality assurance, and modular designs for flexibility. These innovations have not only increased production rates but also improved packaging quality and consistency.

Industry-Specific Adaptations

As cartoning technology evolved, it began to specialize to meet the unique needs of different industries. Pharmaceutical cartoning machines, for instance, are designed to handle delicate products and comply with strict regulatory requirements. Food industry cartoners often feature hygienic designs and materials to ensure food safety. Cosmetics packaging requires machines that can handle a variety of product shapes and sizes while maintaining an aesthetically pleasing presentation.

This specialization has led to a diverse range of cartoning solutions, each tailored to specific product types and packaging requirements. The ability to customize cartoning machines has become a key factor in their widespread adoption across various sectors.

Key Components and Functions of Automatic Cartoning Machines

Carton Magazine and Feeding System

The carton magazine is the starting point of the cartoning process. It holds a stack of flat carton blanks ready for use. The feeding system is responsible for separating individual cartons from the stack and introducing them into the machine. Advanced feeders use vacuum or mechanical grippers to ensure reliable and consistent carton picking, even at high speeds.

Modern cartoning machines often feature easy-load magazines that allow operators to replenish carton stocks without stopping the machine, enhancing overall efficiency. Some systems also incorporate sensors to detect low carton levels and alert operators, preventing production interruptions.

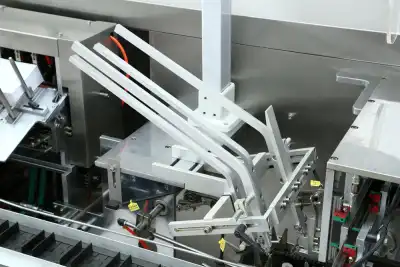

Carton Erection and Product Insertion

Once a carton is fed into the machine, it undergoes the erection process. This involves unfolding the flat blank and forming it into the three-dimensional carton shape. Precision is crucial at this stage to ensure the carton is properly squared and ready to receive the product.

Product insertion is perhaps the most critical function of an automatic cartoning machine. Depending on the product type, various insertion methods may be employed. For example, pick-and-place robotic arms can handle delicate items, while pusher mechanisms are suitable for more robust products. Many machines feature multiple insertion stations to accommodate complex packaging requirements or multi-product combinations.

Closing and Sealing Mechanisms

After product insertion, the carton must be securely closed and sealed. This typically involves folding the remaining flaps and applying an adhesive or using a mechanical locking system. Hot melt glue applicators are common in many cartoning machines, offering a strong and reliable seal.

For tamper-evident packaging, additional sealing features may be incorporated. These can include perforated tear strips, security labels, or specialized adhesive patterns. The sealing process not only secures the product but also plays a crucial role in maintaining package integrity during shipping and storage.

Optimizing Packaging Efficiency with Advanced Cartoning Techniques

Integration of Smart Technologies

The integration of smart technologies has ushered in a new era of packaging efficiency. Internet of Things (IoT) sensors embedded in cartoning machines can collect real-time data on machine performance, allowing for predictive maintenance and reducing downtime. Artificial Intelligence (AI) algorithms can analyze this data to optimize machine settings and improve overall efficiency.

Augmented Reality (AR) is another cutting-edge technology finding its way into cartoning processes. AR can assist operators in troubleshooting issues, providing step-by-step guidance overlaid on the actual machine. This not only speeds up problem resolution but also reduces the need for extensive training.

Flexible and Modular Design Approaches

Flexibility is key in modern packaging operations, where product lines and packaging requirements can change rapidly. Modular cartoning machines address this need by allowing easy reconfiguration and quick changeovers. These machines feature interchangeable modules that can be swapped out or added as needed, adapting to different carton sizes, product types, or packaging styles.

Some advanced cartoning systems even offer tool-less changeovers, where operators can adjust machine settings and components without specialized tools. This dramatically reduces downtime between production runs and increases overall equipment effectiveness (OEE).

Sustainability Considerations in Cartoning

As environmental concerns take center stage, sustainable cartoning practices are becoming increasingly important. This includes the use of eco-friendly packaging materials, such as recyclable or biodegradable cartons. Automatic cartoning machines are being designed to handle these materials effectively, ensuring that sustainability doesn't come at the cost of efficiency.

Energy efficiency is another critical aspect of sustainable cartoning. Modern machines incorporate energy-saving features like regenerative braking in servo motors and optimized pneumatic systems. Some manufacturers are even exploring the use of renewable energy sources to power cartoning equipment, further reducing the environmental impact of packaging operations.

Conclusion

Mastering cartoning is essential for achieving packaging efficiency in today's competitive market. The evolution of cartoning technology, particularly the development of automatic cartoning machines, has transformed the packaging landscape. By understanding the key components and functions of these machines and embracing advanced techniques, businesses can significantly enhance their packaging operations. As we look to the future, the integration of smart technologies, flexible design approaches, and sustainability considerations will continue to drive innovation in cartoning. By staying informed and adapting to these advancements, companies can ensure they remain at the forefront of packaging efficiency, delivering high-quality products while optimizing their production processes.

Contact Us

Ready to elevate your packaging efficiency with state-of-the-art cartoning solutions? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to explore how our automatic cartoning machines can revolutionize your packaging operations.

References

Johnson, A. (2022). The Evolution of Packaging Automation: From Manual to Intelligent Systems. Journal of Packaging Technology and Research, 15(3), 78-92.

Smith, B. & Lee, C. (2021). Sustainable Packaging Solutions: Balancing Efficiency and Environmental Impact. International Journal of Sustainable Manufacturing, 9(2), 145-160.

Garcia, M. et al. (2023). Smart Factory Integration: IoT and AI in Modern Packaging Equipment. Automation in Packaging, 28(4), 301-315.

Brown, D. (2020). Flexible Packaging Machinery: Adapting to Changing Market Demands. Packaging Engineering Review, 12(1), 55-70.

Zhang, Y. & Wong, K. (2022). Energy Efficiency in Packaging Operations: A Comprehensive Analysis. Journal of Clean Production, 18(6), 423-438.

Taylor, R. (2021). Quality Assurance in Automated Cartoning: Ensuring Consistency and Compliance. Pharmaceutical Packaging Technology, 7(3), 210-225.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?