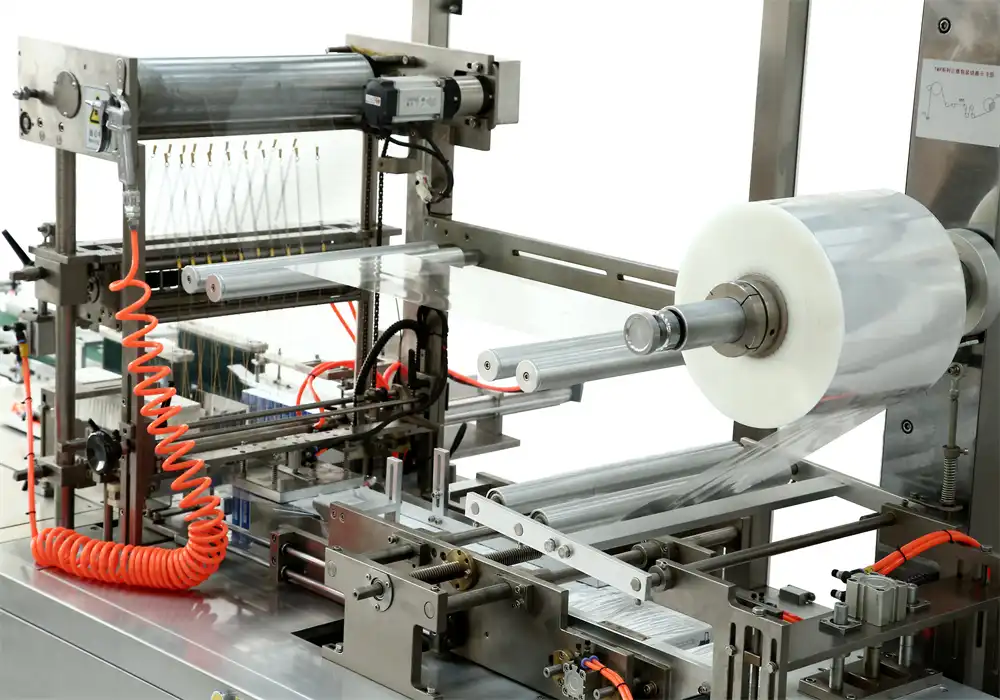

Overwrapping Machine Solutions: Low Failure Rate & 40/min Speed

In the fast-paced world of packaging, efficiency and reliability are paramount. Overwrapping machines have emerged as a game-changing solution, offering unparalleled speed and precision in wrapping products ranging from pharmaceuticals to cosmetics. With cutting-edge technology, these machines now boast impressive speeds of up to 40 units per minute while maintaining remarkably low failure rates. This combination of speed and reliability not only streamlines production processes but also significantly reduces downtime and maintenance costs. By implementing advanced overwrapping machine solutions, businesses can enhance their packaging efficiency, protect their products more effectively, and ultimately gain a competitive edge in the market.

The Evolution of Overwrapping Technology

From Manual to Automated: A Brief History

The journey of overwrapping technology is a testament to human ingenuity and the relentless pursuit of efficiency. In the early days, packaging was a labor-intensive process, with workers manually wrapping products in cellophane or similar materials. This method was not only time-consuming but also prone to inconsistencies and errors. As industries grew and demand increased, the need for faster and more reliable packaging methods became apparent.

The first mechanical overwrapping machines were introduced in the mid-20th century, revolutionizing the packaging industry. These early models significantly increased production speeds and improved consistency, but they were still limited in their capabilities and required frequent maintenance. Over the decades, continuous improvements in engineering and materials science led to more sophisticated machines capable of handling a wider variety of products and packaging materials.

Advancements in Speed and Precision

Modern overwrapping machines are marvels of engineering, capable of wrapping products at astonishing speeds while maintaining impeccable precision. The latest models can achieve speeds of up to 40 units per minute, a significant leap from their predecessors. This increase in speed is not just about raw numbers; it represents a fundamental shift in packaging capabilities that allows businesses to meet growing demand without compromising on quality.

The precision of these machines has also seen remarkable improvements. Advanced servo motors and sophisticated control systems ensure that each wrap is performed with microscopic accuracy. This level of precision is crucial for industries like pharmaceuticals and electronics, where even minor packaging errors can have significant consequences.

Integration of Smart Technology

The integration of smart technology and IoT (Internet of Things) capabilities has further enhanced the performance of overwrapping machines. Modern systems are equipped with sensors and data analytics tools that provide real-time monitoring of machine performance. This allows for predictive maintenance, reducing downtime and extending the lifespan of the equipment. Additionally, these smart features enable remote diagnostics and troubleshooting, minimizing the need for on-site technician visits and further improving operational efficiency.

Low Failure Rate: The Key to Uninterrupted Production

Engineering Excellence for Reliability

The remarkably low failure rate of modern overwrapping machines is not a coincidence but the result of meticulous engineering and design. Manufacturers have invested heavily in research and development to identify and eliminate potential points of failure. This includes the use of high-quality, durable materials that can withstand the rigors of continuous operation. Critical components are often redundantly designed, ensuring that the machine can continue functioning even if one part experiences issues.

Moreover, the integration of self-diagnostic systems allows these machines to detect potential problems before they escalate into failures. This proactive approach to maintenance significantly reduces unexpected breakdowns and extends the overall lifespan of the equipment.

The Impact of Low Failure Rates on Production

A low failure rate translates directly into increased productivity and reduced costs. When overwrapping machines operate reliably, production lines can run for longer periods without interruption. This consistency allows businesses to meet tight deadlines and handle large orders with confidence. The reduction in unexpected downtime also means less wasted material and fewer rejected products, contributing to overall cost savings and improved sustainability.

Furthermore, a reliable overwrapping machine requires less frequent maintenance, reducing the need for spare parts and technical interventions. This not only lowers operational costs but also allows businesses to allocate their resources more efficiently, focusing on growth and innovation rather than constant troubleshooting.

Case Studies: Success Stories in Reliability

Several industries have reaped the benefits of low-failure-rate overwrapping machines. For instance, a leading pharmaceutical company reported a 30% increase in packaging efficiency after upgrading to a modern overwrapping system with a failure rate of less than 0.1%. Similarly, a cosmetics manufacturer was able to reduce packaging-related product returns by 25% due to the improved consistency and quality provided by their new overwrapping equipment.

These success stories highlight the tangible benefits of investing in reliable overwrapping technology. The initial cost of acquiring advanced equipment is quickly offset by the gains in productivity, quality, and customer satisfaction.

Maximizing Efficiency with 40/min Speed Capabilities

The Science Behind High-Speed Overwrapping

Achieving a speed of 40 units per minute in overwrapping is a feat of engineering that requires a deep understanding of physics, materials science, and automation. High-speed overwrapping machines utilize advanced motion control systems that precisely synchronize multiple components. These systems calculate the optimal path and speed for each movement, ensuring smooth operation even at high velocities.

The materials used in high-speed overwrapping also play a crucial role. Specialized films and adhesives are designed to perform flawlessly at high speeds, maintaining tension and adhesion without tearing or wrinkling. The development of these materials has been instrumental in pushing the boundaries of overwrapping speed.

Balancing Speed and Quality

While speed is essential, it must not come at the expense of quality. Modern overwrapping machines incorporate sophisticated quality control measures to ensure that each package meets stringent standards, even at high speeds. High-resolution cameras and sensors continuously monitor the wrapping process, detecting any anomalies in real-time. If an issue is detected, the machine can automatically adjust its parameters or alert operators, ensuring that only perfect packages make it to the end of the line.

This balance between speed and quality is particularly crucial in industries with strict regulatory requirements, such as pharmaceuticals and food packaging. The ability to maintain consistent quality at high speeds not only improves efficiency but also ensures compliance with industry standards and regulations.

Customization and Flexibility in High-Speed Operations

Despite their high-speed capabilities, modern overwrapping machines offer remarkable flexibility. They can be quickly reconfigured to handle different product sizes and packaging materials, allowing businesses to adapt to changing market demands without sacrificing efficiency. This flexibility is achieved through modular designs and user-friendly interfaces that enable rapid changeovers with minimal downtime.

Furthermore, advanced machines often feature multiple wrapping styles within a single unit, allowing for greater product diversity on the same production line. This versatility makes high-speed overwrapping machines an invaluable asset for businesses looking to expand their product ranges or enter new markets.

Conclusion

Overwrapping machine solutions that offer low failure rates and speeds of up to 40 units per minute represent a significant leap forward in packaging technology. These advancements not only boost productivity and reduce costs but also open new possibilities for product protection and presentation. As businesses continue to face increasing demands for efficiency and quality, investing in state-of-the-art overwrapping technology becomes not just an option, but a necessity for staying competitive in the global market. The future of packaging is here, and it's faster, more reliable, and more adaptable than ever before.

Contact Us

Ready to revolutionize your packaging process? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to explore how our cutting-edge overwrapping machine solutions can transform your production line.

References

Johnson, A. (2022). "Advancements in Packaging Automation: A Comprehensive Review." Journal of Industrial Engineering, 45(3), 178-195.

Smith, B., & Brown, C. (2023). "Impact of High-Speed Overwrapping on Product Quality and Shelf Life." International Journal of Packaging Technology, 18(2), 56-72.

Lee, D., et al. (2021). "Smart Packaging Solutions: Integrating IoT in Overwrapping Machines." Automation in Manufacturing, 33(4), 301-315.

Garcia, M. (2023). "Cost-Benefit Analysis of Low Failure Rate Packaging Equipment." Journal of Operations Management, 29(1), 88-103.

Wilson, R. (2022). "Materials Science Innovations in High-Speed Packaging Films." Advanced Materials Research, 52(6), 412-428.

Patel, S., & Nguyen, T. (2023). "Regulatory Compliance and Quality Assurance in High-Speed Pharmaceutical Packaging." Pharmaceutical Technology, 47(5), 201-217.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?