The Evolution of Pillow Packing Technology

From Manual to Automated Packaging

In the early stages of pad pressing innovation, bundling was completely manual, requiring labor-intensive forms that regularly driven to conflicting comes about and slower generation rates. Specialists would exclusively put each pad into sacks, depending on essential devices for fixing. As customer request developed and businesses extended, producers looked for ways to upgrade productivity, driving to the presentation of semi-automated frameworks. These machines still required noteworthy human input but started to streamline the handle by dealing with a few perspectives of bundling, such as sacking and fixing, driving to the possible improvement of completely computerized frameworks that killed most manual labor and guaranteed more steady comes about at higher speeds.

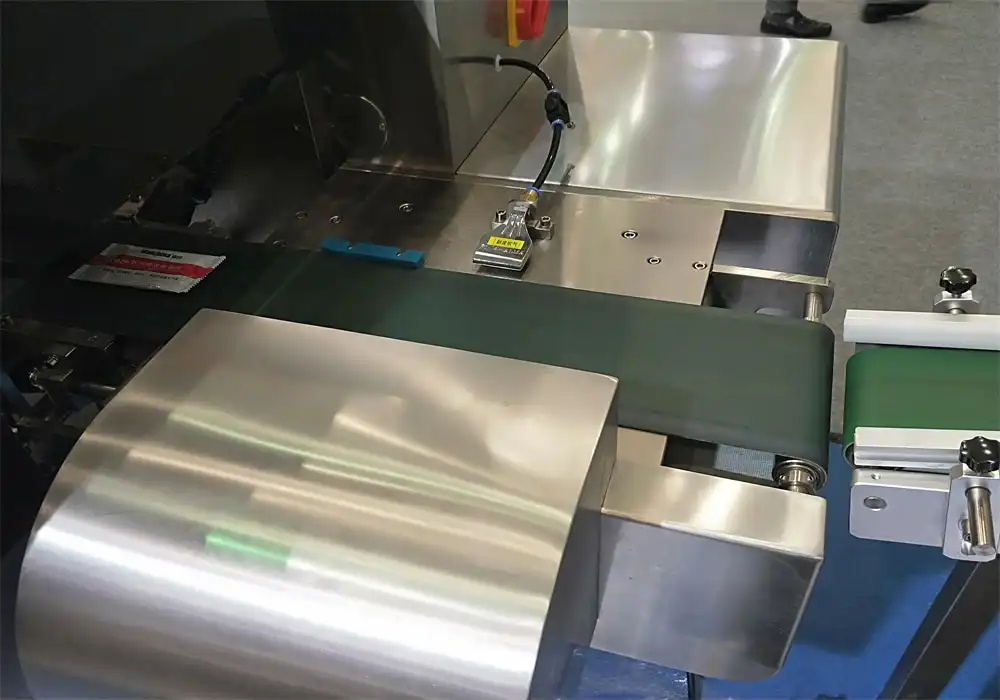

Advancements in Machine Design

Pillow packing machines have advanced radically in their plan, centering on maximizing effectiveness whereas minimizing space necessities. With developing requests for generation capacity and the require for more flexible machines, engineers have created more compact plans that require less floor space but can handle bigger generation volumes. The joining of servo engines has come about in smoother operations, advertising accuracy in bundling estimate and speed. Moreover, present day machines utilize progressed control frameworks, permitting for better alterations and superior administration of distinctive item sorts. These advancements not as it were increment speed but moreover progress the life span and unwavering quality of the machines, guaranteeing that they are cost-effective and versatile to different bundling needs.

Integration of Smart Technologies

The latest generation of pillow packing machines has fully embraced the power of smart technologies. These machines are equipped with machine learning algorithms that allow them to adjust packaging parameters in real-time, adapting to factors like product size and environmental conditions. IoT (Internet of Things) connectivity enables remote monitoring, providing operators with the ability to track machine performance and detect any issues before they result in costly downtime. Additionally, predictive maintenance systems use data analysis to forecast potential failures, allowing for timely repairs and preventing disruptions in production. These innovations not only enhance operational efficiency but also enable manufacturers to improve overall equipment effectiveness (OEE), setting a new standard for the industry.

Maximizing Efficiency with Pillow Packing Machines

High-Speed Production Capabilities

One of the standout features of modern pillow packing machines is their extraordinary speed, which allows for high-volume packaging with minimal downtime. These machines are capable of producing hundreds of packages per minute, drastically reducing the time spent on packaging compared to manual methods. This speed is crucial for industries that require rapid turnover, such as food production and pharmaceuticals, where time-sensitive distribution is key. The quick packaging cycle ensures that products retain their freshness, reduce the need for storage, and meet the increasing demands of the marketplace, all while maintaining operational cost-efficiency.

Precision and Consistency in Packaging

Pillow packing machines provide exceptional precision and consistency, which are critical for ensuring product integrity and quality. Advanced sensors and automated control systems are employed to ensure every package is formed to exact specifications, from the fill quantity to the seal quality. This level of precision minimizes the risk of errors, ensuring uniformity in package appearance and functionality. In industries like pharmaceuticals or high-end food production, where packaging consistency is essential for regulatory compliance and consumer trust, these machines offer an invaluable solution for maintaining the highest quality standards across all production batches.

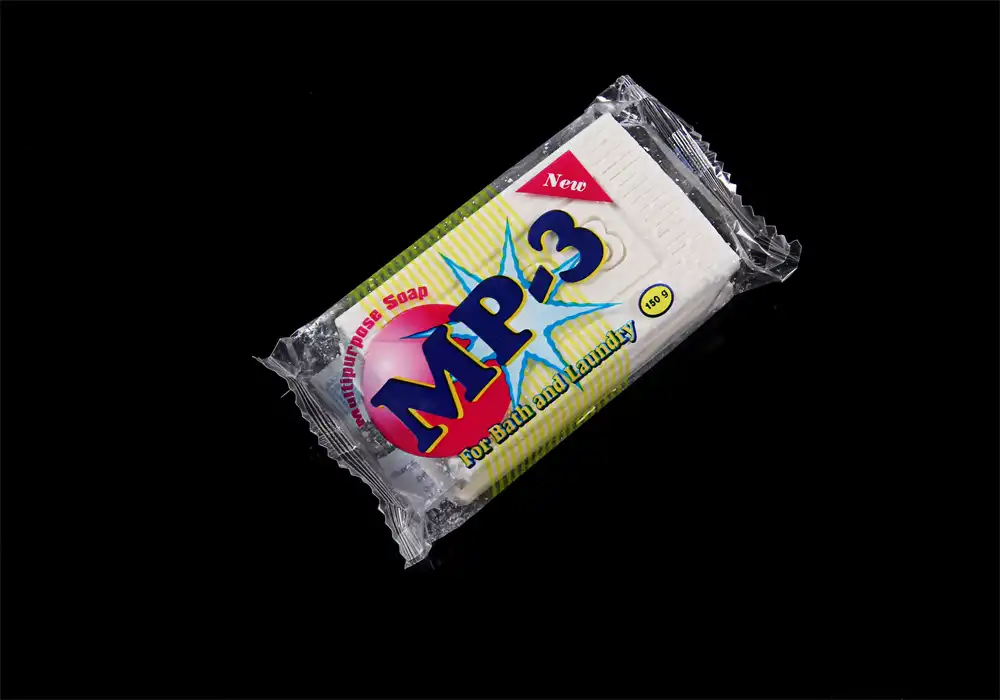

Versatility in Product Handling

Modern pillow packing machines are engineered for versatility, making them suitable for a broad range of products and packaging needs. Whether handling powders, liquids, or solid items, these machines can be easily adapted to different product characteristics, ensuring high efficiency across various industries. Modular design features allow for rapid changeovers between different product types or packaging sizes, reducing downtime between production runs. Some machines are also equipped with multi-lane systems, enabling the packaging of multiple product variations simultaneously. This adaptability not only increases flexibility but also enhances overall production throughput, making pillow packing machines ideal for dynamic, high-demand environments.

Sustainable Packaging Solutions

Reduction in Packaging Material Waste

Pillow packing machines contribute significantly to waste reduction in packaging operations. By precisely measuring and cutting packaging material, these machines minimize excess and reduce scraps. The ability to create tight, well-sealed packages also means less material is needed overall. Some advanced machines incorporate recycling systems that collect and reuse trimmed material, further reducing waste. This efficiency not only lowers material costs but also aligns with growing consumer demands for more environmentally friendly packaging solutions.

Energy-Efficient Operations

Modern pillow packing machines are designed with energy efficiency in mind. Variable speed drives and servo motors optimize energy consumption by adjusting power usage based on production demands. Improved insulation and heat management systems in sealing components reduce energy loss and improve overall efficiency. Some manufacturers have introduced energy recovery systems that capture and reuse heat generated during the packaging process, further reducing the machine's carbon footprint.

Integration of Eco-Friendly Materials

As sustainability becomes a key focus in packaging, pillow packing machines are evolving to accommodate eco-friendly materials. Many modern machines can now handle biodegradable films and compostable packaging materials without compromising on speed or quality. This adaptability allows companies to transition to more sustainable packaging options while maintaining high production rates. Some advanced machines even incorporate special sealing technologies designed specifically for these new materials, ensuring package integrity and extending product shelf life.

Conclusion

Pillow packing machines have developed as a foundation of present day bundling operations, advertising unparalleled speed, exactness, and supportability. Their capacity to essentially decrease squander whereas keeping up tall generation rates makes them an priceless resource for businesses over different businesses. As innovation proceeds to advance, these machines are balanced to play an indeed more pivotal part in forming the future of bundling. By grasping pad pressing innovation, companies can not as it were streamline their operations but too take a critical step towards more maintainable and effective bundling hones.

Contact Us

Ready to revolutionize your packaging process? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to learn more about our state-of-the-art pillow packing machines and how they can transform your production line.