Pros & Cons of New Carton Box Packing Machine

When considering an investment in a carton box packing machine, weighing the benefits against the potential drawbacks is pivotal for any business in the packaging industry. These machines, designed to streamline the packaging process, offer a blend of efficiency and innovation, particularly for sectors like pharmaceuticals, cosmetics, commodities, and foodstuff. On the positive side, they enhance productivity, reduce labor costs, and ensure consistent packaging quality, meeting stringent industry standards. However, challenges such as high initial costs, maintenance needs, and potential operational complexities may arise. Understanding these aspects helps manufacturers globally make informed decisions, ensuring their packaging operations align with both current demands and future growth.

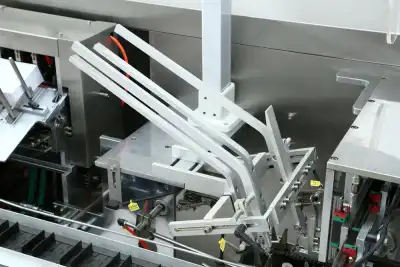

Unveiling the Advantages of Modern Carton Box Packing Machines

Modern packaging equipment, such as the carton box packing machine, has transformed the way businesses handle their packaging needs. These sophisticated systems are engineered to deliver unparalleled efficiency, making them indispensable for manufacturers aiming to stay competitive in a global market. Below, we explore the key benefits that make these machines a worthy investment.

Boosting Operational Efficiency

One of the standout features of a carton box packing machine is its ability to significantly enhance operational throughput. By automating the packing process, these machines can handle large volumes of products with minimal human intervention. This not only accelerates production timelines but also allows businesses to meet tight deadlines, especially during peak seasons. For industries like pharmaceuticals and foodstuff, where speed and precision are paramount, this efficiency translates into a competitive edge. Moreover, the integration of advanced technologies ensures that each carton is packed with meticulous accuracy, reducing errors and waste.

Ensuring Compliance with Industry Standards

In today's regulatory landscape, adherence to standards like CE, ISO9001, and cGMP is non-negotiable, particularly for global manufacturers. A high-quality carton box packing machine is designed to meet these stringent requirements, ensuring that every package is safe, secure, and compliant. This is especially critical for sectors such as pharmaceuticals and cosmetics, where packaging integrity directly impacts product safety and consumer trust. By investing in equipment that aligns with these standards, businesses can confidently expand into international markets, knowing their packaging processes meet global benchmarks.

Reducing Long-Term Operational Costs

While the initial outlay for a carton box packing machine may seem substantial, the long-term financial benefits are compelling. Automation reduces the reliance on manual labor, which in turn lowers labor costs and minimizes the risk of human error. Additionally, these machines are engineered for durability, requiring less frequent replacements compared to manual or semi-automated systems. Over time, the reduction in waste, improved efficiency, and lower labor expenses contribute to a robust return on investment, making these machines a cost-effective solution for businesses aiming to scale their operations.

Navigating the Challenges of Carton Box Packing Machines

While the advantages of a carton box packing machine are undeniable, it's equally important to consider the potential hurdles that may accompany their adoption. Being aware of these challenges allows businesses to plan effectively, ensuring a smoother integration into their existing operations. Here, we delve into the key drawbacks that manufacturers should keep in mind.

High Initial Investment Costs

One of the most significant barriers to adopting a carton box packing machine is the upfront cost. These machines, equipped with cutting-edge technology and robust engineering, often come with a hefty price tag. For small to medium-sized enterprises, this initial expenditure can strain budgets, especially if additional financing is required. Beyond the cost of the machine itself, businesses must also account for expenses related to installation, training, and potential modifications to existing production lines. While the long-term savings are substantial, the initial financial commitment can be a daunting prospect for some.

Maintenance and Technical Expertise Requirements

A carton box packing machine, like any sophisticated piece of equipment, requires regular maintenance to ensure optimal performance. This includes routine inspections, software updates, and occasional repairs, all of which can add to operational costs. Furthermore, operating and troubleshooting these machines often demands a certain level of technical expertise. Businesses may need to invest in training programs for their staff or hire specialized technicians, particularly if the machine features advanced automation or integration with other packaging systems. Without proper maintenance and skilled personnel, the risk of downtime increases, potentially disrupting production schedules.

Potential Integration Complexities

Integrating a new carton box packing machine into an existing production line can present logistical challenges. Depending on the current setup, businesses may need to reconfigure workflows, upgrade supporting equipment, or even redesign their facility layout to accommodate the new system. This process can be time-consuming and may lead to temporary disruptions in production. Additionally, compatibility issues with existing machinery, such as cellophane overwrapping or flow pack systems, could arise, requiring further investment in adapters or auxiliary equipment. For global manufacturers with diverse product lines, ensuring seamless integration across multiple facilities adds another layer of complexity.

Making an Informed Decision for Your Packaging Needs

Choosing whether to invest in a carton box packing machine is a decision that requires careful consideration of your business's unique needs, goals, and resources. By evaluating the broader implications of this investment, manufacturers can determine whether this technology aligns with their operational strategy. Below, we explore key factors to consider when making this decision.

Assessing Your Production Volume and Goals

The suitability of a carton box packing machine largely depends on your production volume and long-term objectives. For businesses with high output demands, such as those in the pharmaceutical or foodstuff sectors, the automation and efficiency offered by these machines are often indispensable. However, for smaller operations with lower production volumes, the benefits may not justify the costs. It's essential to analyze your current output, forecast future growth, and determine whether the machine's capacity aligns with your needs. This assessment ensures that your investment supports both immediate requirements and future scalability.

Evaluating Compatibility with Existing Systems

Before committing to a carton box packing machine, it's crucial to evaluate how well it will integrate with your existing packaging infrastructure. Consider whether the machine can work in tandem with other equipment, such as cartoning machines, overwrapping systems, or flow pack machines, to create a cohesive packaging line. Compatibility issues can lead to inefficiencies, increased costs, and production delays, so it's wise to consult with equipment providers to ensure a seamless fit. For global manufacturers, this evaluation should extend across all facilities to maintain consistency and efficiency in operations worldwide.

Balancing Cost Against Long-Term Value

While the initial cost of a carton box packing machine can be significant, it's important to view this investment through the lens of long-term value. Consider the potential savings in labor, waste reduction, and increased productivity, as well as the machine's durability and compliance with industry standards. For businesses aiming to expand into new markets, the ability to meet global regulatory requirements can open doors to new opportunities, further enhancing the machine's value. By conducting a thorough cost-benefit analysis, manufacturers can make a decision that supports both their financial health and strategic growth.

Conclusion

A carton box packing machine offers a powerful solution for manufacturers seeking to enhance efficiency, ensure compliance, and reduce costs in their packaging operations. However, the high initial investment, maintenance needs, and integration challenges require careful consideration. By weighing these pros and cons against your specific business needs, you can determine whether this technology is the right fit for your global operations, ensuring a decision that drives long-term success.

Contact Us

Ready to explore how a carton box packing machine can transform your packaging process? Contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected] for expert advice and tailored solutions.

References

Smith, J. (2023). Automation in Packaging: Balancing Efficiency and Cost in Modern Manufacturing. Industrial Press.

Patel, R. (2022). Global Packaging Standards: Navigating CE, ISO, and cGMP Compliance. Packaging World Publishing.

Nguyen, T. (2021). The Future of Carton Packaging: Innovations and Challenges. Journal of Packaging Technology.

Brown, L. (2020). Cost-Benefit Analysis of Automated Packaging Systems. Manufacturing Insights Press.

Kim, S. (2019). Integration Strategies for Advanced Packaging Machinery. Global Manufacturing Review.

Garcia, M. (2023). Scaling Production: The Role of Packaging Automation in Global Markets. International Business Press.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?