Supplement Manufacturing Equipment: A Complete Guide

In the ever-evolving world of dietary supplements, efficient manufacturing processes are crucial for success. This comprehensive guide explores the essential equipment needed for supplement production, with a focus on cutting-edge packaging solutions. From blister cartoning machines to advanced blister packaging machines for pharmacy applications, we'll delve into the key components that drive modern supplement manufacturing. Whether you're a seasoned manufacturer or just starting out, this guide will provide valuable insights to help you optimize your production line and meet the growing demand for high-quality supplements.

The Backbone of Supplement Production: Essential Equipment

Mixing and Blending Systems

At the heart of supplement manufacturing lies the crucial process of mixing and blending ingredients. High-performance mixing systems ensure uniform distribution of active ingredients, excipients, and additives. These machines range from simple V-blenders to more sophisticated ribbon blenders and high-shear mixers. The choice depends on the specific formulation requirements and production scale.

Granulation Equipment

Granulation is often necessary to improve flow properties and compressibility of powder blends. Wet granulation equipment, such as high-shear mixers and fluid bed dryers, are commonly used in supplement manufacturing. For heat-sensitive ingredients, dry granulation methods using roller compactors or slugging machines may be preferred, especially when production is integrated with blister packaging machines for pharmacy.

Tablet Compression Machines

For solid dosage forms, tablet compression machines are indispensable. Modern rotary tablet presses can produce thousands of tablets per minute with precise weight and hardness control. These machines often feature multiple compression stations and can accommodate various tablet shapes and sizes.

Packaging Innovations: Blister Packaging Machines for Pharmacy and Beyond

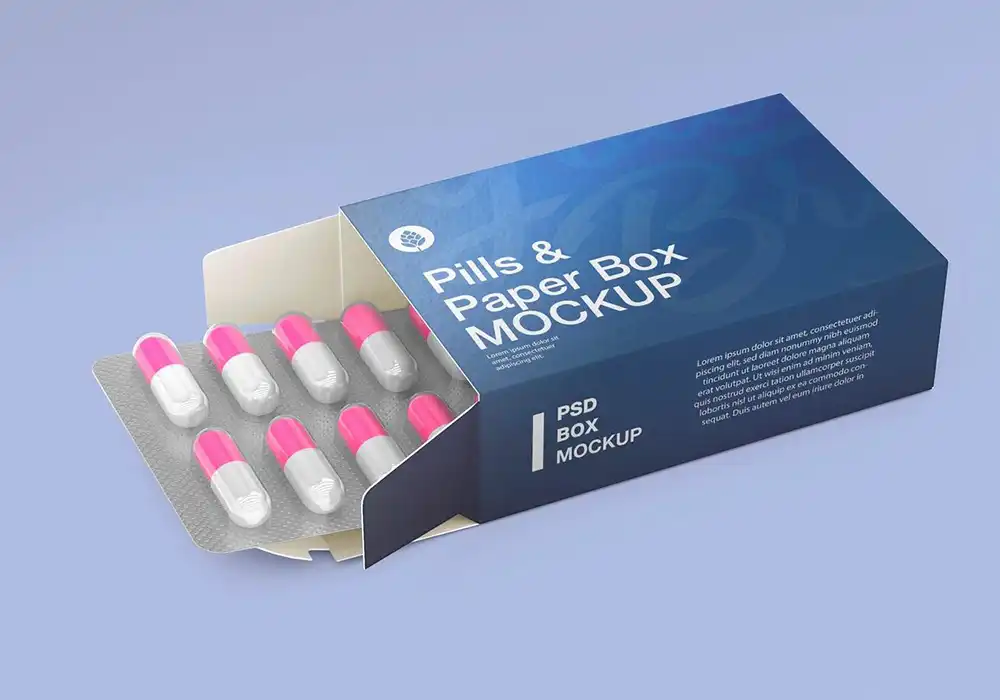

The Rise of Blister Packaging

Blister packaging has seen significant growth in the supplement and pharmaceutical industries due to its excellent protective properties. It safeguards products from moisture, oxygen, and contamination, which is especially crucial for maintaining the stability and potency of tablets and capsules. Blister packaging machines for pharmacy applications are now engineered to handle diverse product types and a variety of packaging materials, including PVC, PVDC-coated films, and aluminum foils. Their versatility and ability to meet strict regulatory and hygiene standards make them a preferred choice for high-quality, tamper-evident packaging solutions.

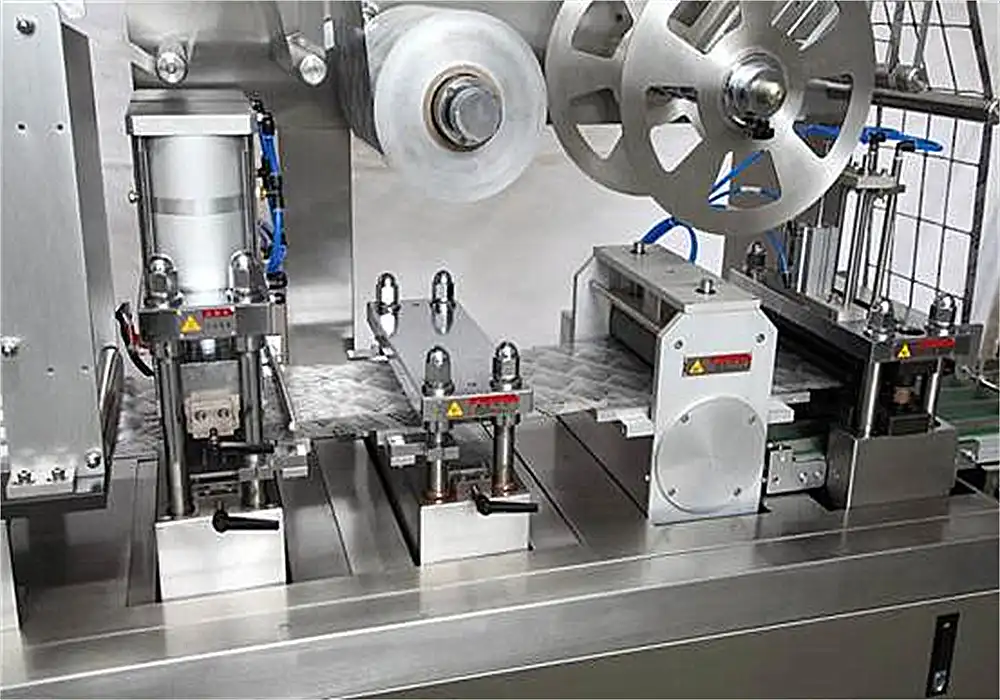

Blister Forming and Sealing

At the core of blister packaging technology is thermoforming, a process that shapes heated plastic film into uniform cavities using precision molds. Once the blisters are formed, tablets or capsules are accurately placed into them, either manually or via automated feeding systems. A backing material - usually aluminum foil or laminated film - is then applied and sealed using heat and pressure. Advanced sealing mechanisms ensure an airtight and secure closure, protecting contents from environmental threats like moisture, air, and light, while also supporting extended shelf life and regulatory compliance.

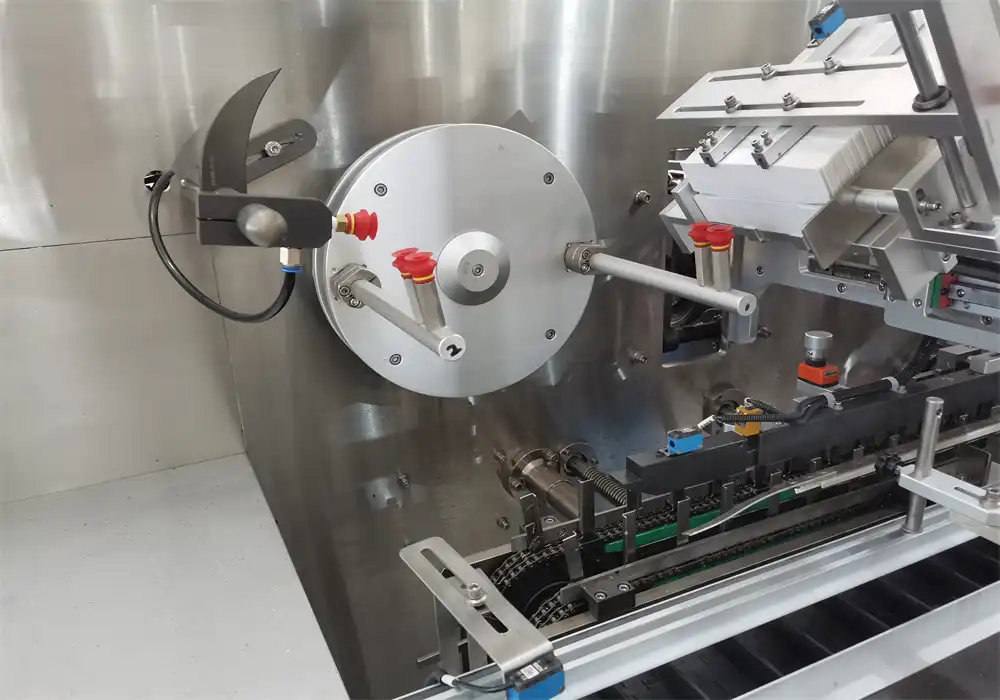

Integration with Cartoning Systems

To enhance packaging line efficiency, manufacturers increasingly implement systems that combine blister forming, filling, and sealing with automatic cartoning. These integrated blister cartoning machines eliminate the need for separate handling, reducing manual labor and the risk of misalignment. The blisters are directly transferred and inserted into cartons with high precision, speeding up production and improving throughput. This seamless integration allows manufacturers to optimize workflow, reduce equipment footprint, and maintain product traceability. It is particularly valuable for large-scale pharmaceutical and supplement operations seeking consistency and scalability in their packaging processes.

Optimizing Production: Advanced Features and Considerations

Quality Control and Inspection Systems

Ensuring product quality is a critical aspect of supplement manufacturing, particularly for pharmaceutical-grade blister packaging. Modern production lines often incorporate advanced inspection technologies such as high-resolution vision cameras, checkweighers, and seal integrity scanners. These systems automatically detect anomalies like broken tablets, incorrect counts, misaligned labels, or compromised seals. By identifying defects in real-time, manufacturers can reduce waste, prevent costly recalls, and maintain regulatory compliance. The integration of such automated inspection systems also supports continuous improvement and enhances overall production efficiency while safeguarding consumer trust in the final product.

Flexibility and Quick Changeovers

Manufacturers face increasing pressure to accommodate diverse product ranges and smaller batch sizes. Blister packaging machines for pharmacy now feature modular configurations and tool-less changeovers, enabling rapid transitions between different blister formats, foil types, or tablet sizes. This flexibility is essential for responding quickly to market demands and minimizing downtime between production runs. Quick-change tooling and programmable settings allow operators to switch formats with minimal manual intervention. This level of adaptability not only improves production efficiency but also supports lean manufacturing principles and reduces the need for maintaining large inventories of pre-packed products.

Data Management and Industry 4.0 Integration

Industry 4.0 technologies are transforming how supplement manufacturing facilities operate. Advanced equipment, such as tablet presses, blister packaging systems, and automatic cartoning machines, now comes equipped with sensors and software that enable real-time data acquisition and analysis. This digital infrastructure supports predictive maintenance by identifying equipment wear before failure occurs, and it allows for continuous monitoring of key performance indicators. Additionally, traceability is enhanced through digital batch records and automated quality logs. These smart capabilities not only improve operational decision-making but also help ensure regulatory compliance and consistent product quality.

Conclusion

The landscape of supplement manufacturing equipment continues to evolve, driven by technological advancements and changing market demands. From the initial mixing and granulation stages to the final packaging steps, each piece of equipment plays a crucial role in producing high-quality supplements. By investing in state-of-the-art machinery, such as advanced blister packaging machines for pharmacy applications and integrated blister cartoning machines, manufacturers can enhance their production efficiency, ensure product integrity, and stay competitive in the dynamic supplement market.

Contact Us

Ready to elevate your supplement manufacturing capabilities? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to explore our range of innovative packaging solutions tailored for the pharmaceutical and supplement industries.

References

Smith, J. (2023). Advances in Pharmaceutical Packaging Technology. Journal of Drug Delivery Science and Technology, 65, 102-115.

Brown, A. et al. (2022). Quality Control in Supplement Manufacturing: A Comprehensive Review. International Journal of Pharmaceutics, 618, 121-135.

Johnson, R. (2021). Industry 4.0 in Pharmaceutical Manufacturing: Opportunities and Challenges. Trends in Pharmacological Sciences, 42(8), 680-694.

Lee, S. & Park, K. (2023). Blister Packaging: Innovations and Applications in the Supplement Industry. Packaging Technology and Science, 36(5), 521-536.

Garcia, M. (2022). Sustainable Packaging Solutions for Dietary Supplements. Journal of Cleaner Production, 330, 129-143.

Thompson, D. et al. (2023). Optimization of Tablet Compression Processes in Supplement Manufacturing. AAPS PharmSciTech, 24(6), 237-252.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?