Understanding Blister Cartoning Technology

The Evolution of Packaging Automation

Packaging automation has come a long way since its inception. The advent of blister cartoning machines marks a significant milestone in this evolution. These sophisticated devices represent the culmination of years of engineering and innovation in the packaging industry. By automating the process of inserting blister packs into cartons, these machines have addressed many of the challenges faced by manufacturers in terms of efficiency, consistency, and quality control.

Key Components of Blister Cartoning Machines

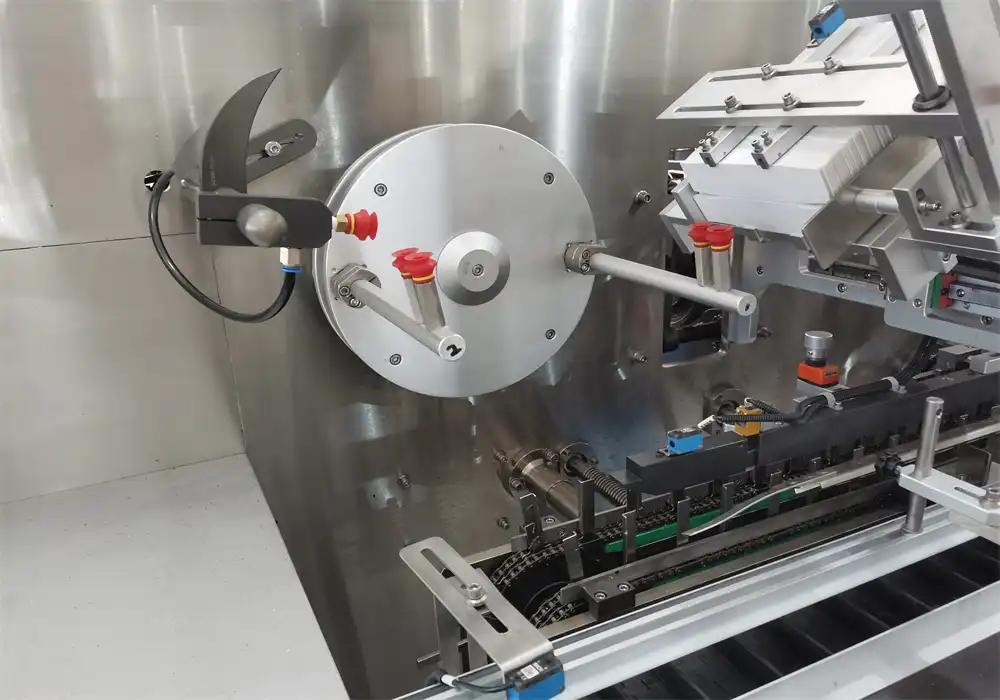

To appreciate the benefits of blister cartoning machines, it's essential to understand their key components. These machines typically consist of several integrated systems: - Blister feed system: Accurately positions blister packs for insertion - Carton magazine: Stores and dispenses flat cartons - Carton erecting mechanism: Opens and shapes cartons for filling - Insert station: Places product information leaflets or other materials - Closing and sealing system: Secures the filled carton Each component works in harmony to ensure smooth operation and optimal packaging results.

Integration with Existing Packaging Lines

One of the most valuable aspects of modern blister cartoning machines is their ability to integrate seamlessly with existing packaging lines. Manufacturers can incorporate these machines into their current setups with minimal disruption to operations. This integration capability allows for a phased approach to automation, enabling companies to gradually upgrade their packaging processes while maintaining production continuity.

Exploring the Benefits in Detail

Accelerated Production Rates

Blister cartoning machines significantly boost production speeds compared to manual packaging methods. Advanced models can handle hundreds of cartons per minute, dramatically increasing output. This acceleration in production rates allows manufacturers to meet growing demand, handle larger orders, and reduce lead times for their customers. The enhanced speed also provides a competitive edge in fast-paced markets where quick turnaround is crucial.

Consistency and Quality Assurance

One of the standout benefits of blister cartoning machines is their ability to maintain consistent packaging quality. These machines eliminate human error, ensuring that each carton is filled and sealed to the same high standard. This consistency not only improves the overall appearance of the packaged product but also enhances brand perception. Quality assurance features, such as vision systems and weight checks, further guarantee that only correctly packaged products reach the consumer.

Cost-Effectiveness and ROI

While the initial investment in a blister cartoning machine may seem substantial, the long-term cost savings are significant. By reducing reliance on manual labor, companies can reallocate human resources to more value-added tasks. The increased production efficiency leads to lower per-unit packaging costs, contributing to improved profit margins. Moreover, the reduction in packaging errors and waste translates to additional savings, making these machines a cost-effective solution with a strong return on investment.

Addressing Industry-Specific Challenges

Pharmaceutical Packaging Solutions

In the pharmaceutical industry, packaging plays a critical role in ensuring product safety and compliance. Blister cartoning machines are particularly well-suited to meet the stringent requirements of this sector. They offer precise control over the packaging process, maintaining the integrity of sensitive medications. These machines can be configured to handle various blister pack sizes and carton designs, accommodating the diverse range of pharmaceutical products. Additionally, they can incorporate tamper-evident features and serialization capabilities to enhance product security and traceability.

Cosmetics and Personal Care Applications

The cosmetics and personal care industry demands packaging that not only protects the product but also enhances its visual appeal. Blister cartoning machines excel in this area by providing consistent, high-quality packaging that showcases the product effectively. These machines can handle delicate items such as compact powders, lipsticks, and skincare products with care, ensuring they reach consumers in pristine condition. The flexibility of blister cartoning machines allows for easy adaptation to seasonal packaging changes or limited-edition product runs, which are common in the cosmetics industry.

Adaptability in Food and Consumer Goods

Blister cartoning machines demonstrate remarkable versatility in the food and consumer goods sectors. They can be adapted to package a wide range of products, from confectionery and snacks to small electronics and household items. This adaptability makes them an invaluable asset for manufacturers with diverse product lines. The machines can be quickly reconfigured to accommodate different product sizes and packaging designs, minimizing downtime between production runs. This flexibility allows companies to respond swiftly to market trends and consumer preferences.

Future Trends and Innovations

Smart Packaging Technologies

The future of blister cartoning machines lies in their integration with smart packaging technologies. Emerging trends include the incorporation of RFID tags and NFC chips into packaging, enabling enhanced product tracking and consumer engagement. Advanced blister cartoning machines are being developed to seamlessly integrate these smart features during the packaging process. This evolution will provide manufacturers with unprecedented levels of supply chain visibility and offer consumers interactive experiences with their purchased products.

Sustainable Packaging Solutions

As environmental concerns take center stage, blister cartoning machine manufacturers are focusing on developing solutions that support sustainable packaging initiatives. This includes machines designed to work with eco-friendly materials such as biodegradable plastics and recyclable cartons. Future innovations may include on-machine recycling capabilities, where waste materials are immediately processed for reuse. These advancements will help companies reduce their environmental footprint while meeting consumer demands for more sustainable packaging options.

Industry 4.0 and IoT Integration

The integration of Industry 4.0 principles and Internet of Things (IoT) technologies is set to revolutionize blister cartoning machines. Future models will likely feature advanced sensors and data analytics capabilities, allowing for real-time monitoring and predictive maintenance. This connectivity will enable manufacturers to optimize their packaging operations continuously, reduce downtime, and improve overall equipment effectiveness. The ability to collect and analyze data from these machines will provide valuable insights for process improvement and quality control.

Conclusion

Blister cartoning machines offer a huge number of benefits that can essentially upgrade bundling operations over different businesses. From expanded generation speeds and moved forward consistency to fetched reserve funds and flexibility, these machines give a competitive edge in today's fast-paced fabricating environment. As innovation proceeds to advance, blister cartoning machines will play an progressively critical part in forming the future of bundling robotization. By grasping these advancements, producers can guarantee they stay at the cutting edge of proficiency, quality, and maintainability in their bundling forms.

Contact Us

For more information on how blister cartoning machines can benefit your specific packaging needs, please contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your business.