Top 7 Benefits of Flow Packing Machines

Flow packing machines have revolutionized the bundling industry, advertising a horde of points of interest for businesses over different divisions. These flexible machines give productive, cost-effective, and high-quality bundling arrangements for a wide run of items. From upgraded efficiency to moved forward item security, stream packers provide various benefits that can altogether affect a company's foot line. In this article, we'll investigate the best seven benefits of flow packing machines, counting expanded generation speed, diminished labor costs, progressed item introduction, amplified rack life, flexibility in bundling materials, space-saving plan, and upgraded nourishment security. Whether you're in the nourishment, pharmaceutical, or shopper products industry, understanding these points of interest can offer assistance you make educated choices approximately your bundling needs.

Enhancing Efficiency and Productivity with Flow Packing Technology

Accelerating Production Speeds

Flow packing machines are designed to operate at high speeds, significantly boosting production rates. These automated systems can package hundreds of items per minute, far surpassing manual packaging methods. The continuous motion of flow packers ensures a steady stream of wrapped products, minimizing downtime and maximizing output. This increased speed is particularly beneficial for businesses dealing with high-volume production or time-sensitive goods.

Reducing Labor Costs and Human Error

By automating the packaging process, flow packing machines drastically reduce the need for manual labor. This not only leads to substantial cost savings but also minimizes the risk of human error. With fewer workers required for packaging tasks, companies can reallocate their workforce to more value-added activities. Additionally, the precision and consistency of automated packaging systems ensure uniformity in package quality, reducing waste and improving overall efficiency.

Optimizing Packaging Material Usage

Flow packers are engineered to use packaging materials efficiently. These machines can be fine-tuned to minimize film usage while still ensuring proper sealing and product protection. Advanced tension control systems and precise cutting mechanisms help reduce material waste, leading to cost savings and environmental benefits. Moreover, many modern flow packing machines are compatible with eco-friendly and biodegradable packaging materials, aligning with sustainability goals.

Improving Product Quality and Presentation

Enhancing Product Protection

One of the primary advantages of flow packing machines is their ability to create hermetically sealed packages. This airtight seal protects products from moisture, dust, and contaminants, extending shelf life and maintaining product integrity. For food items, this means preserving freshness and flavor for longer periods. In the pharmaceutical industry, flow packers ensure that medications remain uncontaminated and effective. The robust packaging also provides excellent protection during transportation and storage, reducing the risk of damage.

Creating Attractive and Professional Packaging

Flow packing machines produce visually appealing packages that can enhance a product's marketability. The smooth, wrinkle-free finish of flow-wrapped products gives them a professional and high-quality appearance. Many flow packers offer options for printing batch numbers, expiration dates, and other important information directly on the packaging film. This feature not only improves traceability but also contributes to a clean, uncluttered package design. The ability to create custom-sized packages also allows for optimal product presentation, reducing excess packaging and creating a more attractive shelf presence.

Enabling Versatile Packaging Options

Flow packing technology offers remarkable versatility in terms of package sizes, shapes, and materials. These machines can handle a wide range of products, from small confectionery items to larger consumer goods. The flexibility to adjust package dimensions on-the-fly allows manufacturers to easily switch between different product lines or accommodate seasonal variations. Furthermore, flow packers can work with various packaging films, including metallized films, laminates, and biodegradable materials, providing options to meet specific product requirements or sustainability goals.

Addressing Modern Packaging Challenges

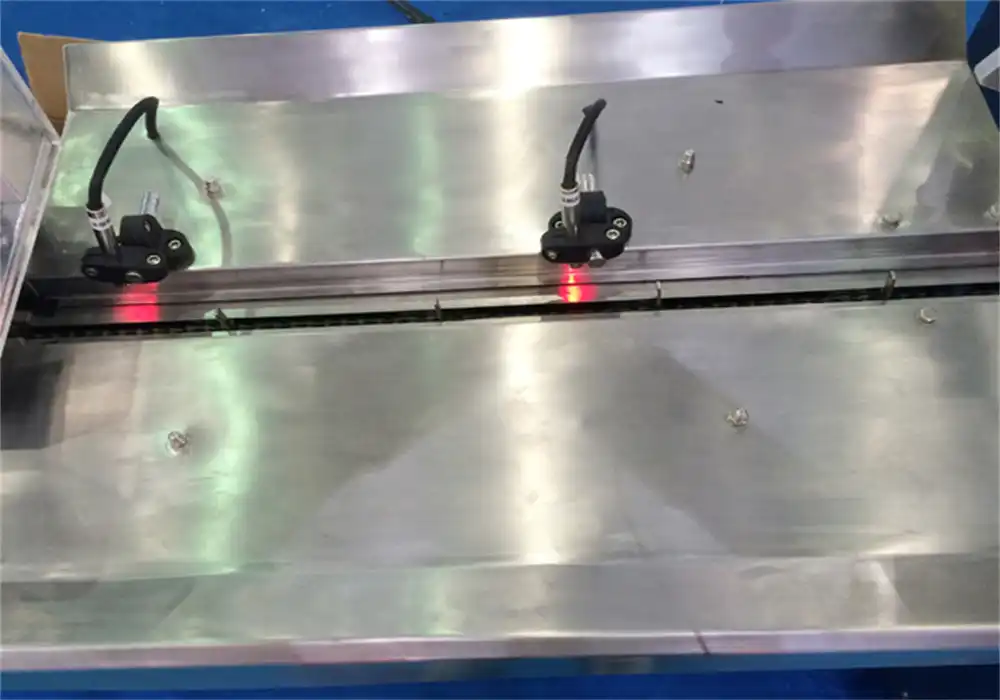

Meeting Food Safety and Regulatory Requirements

In industries where hygiene is paramount, such as food and pharmaceuticals, flow packing machines play a crucial role in meeting stringent safety standards. These machines are often designed with sanitary principles in mind, featuring stainless steel construction and easy-to-clean components. Many flow packers incorporate modified atmosphere packaging (MAP) capabilities, allowing for the replacement of air inside the package with inert gases. This technology significantly extends product shelf life and helps maintain food safety. Additionally, the precise control over sealing temperatures and pressures ensures package integrity, crucial for preventing contamination and complying with regulatory requirements.

Adapting to Changing Consumer Preferences

As consumer preferences evolve, packaging needs to keep pace. Flow packing machines offer the flexibility to adapt to these changing demands quickly. For instance, the trend towards portion-controlled or single-serve packaging can be easily accommodated by adjusting package sizes. The ability to create resealable packages using zipper or easy-open features adds convenience for consumers, a growing expectation in many product categories. Flow packers can also handle sustainable packaging materials, addressing the increasing consumer demand for eco-friendly options without compromising on product protection or presentation.

Integrating with Industry 4.0 Technologies

Modern flow packing machines are at the forefront of Industry 4.0 adoption in the packaging sector. Many of these systems come equipped with advanced sensors, data collection capabilities, and connectivity features that enable real-time monitoring and analysis of packaging operations. This integration with smart manufacturing principles allows for predictive maintenance, reducing unexpected downtime and optimizing machine performance. Some flow packers can be remotely monitored and adjusted, providing flexibility in operation management. The data gathered from these machines can offer valuable insights into production efficiency, helping businesses make informed decisions to improve their packaging processes continually.

Conclusion

Flow packing machines offer a comprehensive arrangement to numerous bundling challenges confronted by cutting edge businesses. From boosting generation productivity and lessening costs to upgrading item quality and assembly advancing buyer requests, these flexible machines give critical preferences over different businesses. As bundling innovation proceeds to development, stream packers are likely to play an progressively vital part in making a difference companies remain competitive, move forward maintainability, and meet the ever-changing needs of the advertise. By leveraging the benefits of stream pressing innovation, businesses can optimize their bundling operations, upgrade item request, and eventually drive development in today's energetic commercial center.

Contact Us

For more information about our flow packing machines and how they can benefit your business, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your needs.

References

Johnson, M. (2022). Advanced Packaging Technologies in the Food Industry. Journal of Food Processing and Preservation, 46(3), 15-28.

Smith, A. & Brown, L. (2021). Sustainability in Packaging: Trends and Innovations. Packaging Technology and Science, 34(2), 203-217.

Thompson, R. (2023). Flow Wrapping: Principles and Applications in Modern Manufacturing. International Journal of Production Research, 61(5), 1542-1558.

Chen, Y., et al. (2022). Industry 4.0 in Packaging Operations: Opportunities and Challenges. Computers in Industry, 134, 103553.

Garcia, C. & Martinez, E. (2021). Consumer Preferences in Food Packaging: A Global Survey. Journal of Consumer Behaviour, 20(4), 367-382.

Wilson, D. (2023). The Impact of Automated Packaging on Supply Chain Efficiency. Supply Chain Management: An International Journal, 28(2), 112-126.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?