What Is a Blister Cartoning Machine Used For?

A blister cartoning machine is a vital piece of equipment in the packaging industry, primarily utilized for efficiently encasing blister packs into cartons. These sophisticated machines automate the process of inserting pre-sealed blister packs containing products such as pharmaceuticals, cosmetics, or small consumer goods into individual cartons. By streamlining this packaging step, blister cartoning machines significantly enhance production speed, improve packaging consistency, and reduce labor costs. They are essential for businesses looking to scale up their packaging operations while maintaining product integrity and presentation quality. The versatility of modern blister cartoning machines allows them to handle various carton sizes and styles, making them indispensable in industries where precise, hygienic, and tamper-evident packaging is paramount.

The Mechanics and Functionality of Blister Cartoning Machines

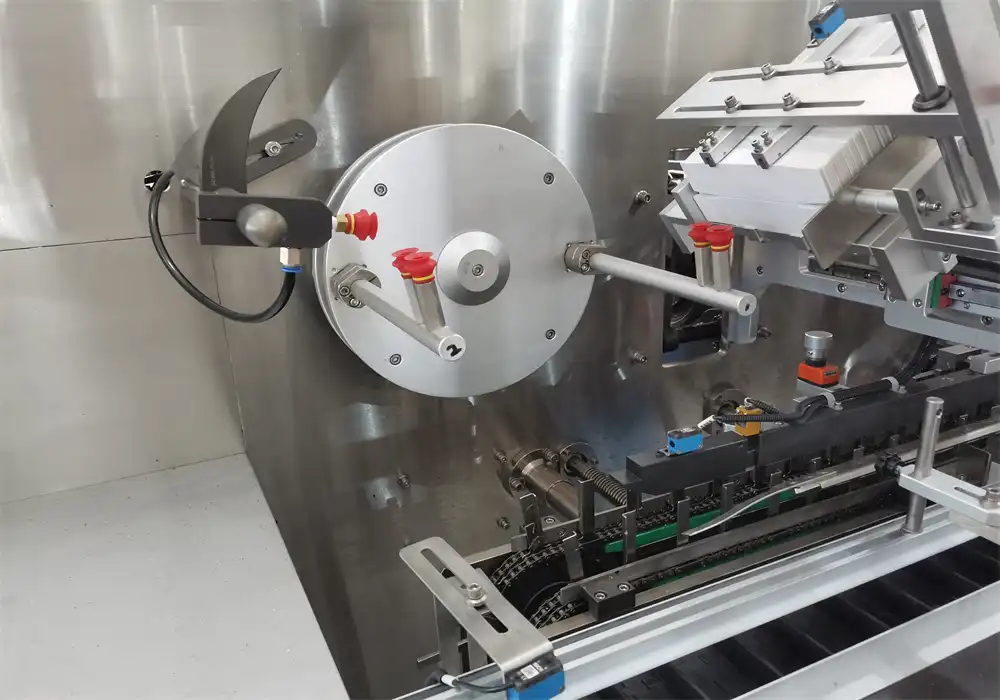

Core Components of a Blister Cartoning Machine

Blister cartoning machines are composed of several key components that work in harmony to deliver efficient packaging results. The carton magazine holds and feeds flat cartons into the machine, while the blister feeder accurately positions blister packs for insertion. A conveyor system moves products through various stages of the packaging process. The folding mechanism carefully folds carton flaps, and the sealing unit ensures the carton is securely closed. Advanced models may include additional features like printing systems for batch numbers or expiration dates, and quality control cameras to verify package integrity.

The Step-by-Step Process of Blister Cartoning

The blister cartoning process begins with the machine erecting a flat carton from the magazine. Simultaneously, the blister pack is positioned for insertion. As the carton moves along the conveyor, the blister pack is precisely placed inside. The machine then folds the carton flaps in a specific sequence, applying adhesive or using a mechanical locking system to seal the package. In more sophisticated setups, the machine may print variable data on the carton before it exits the system. This streamlined process ensures consistent packaging quality at high speeds, significantly outpacing manual methods.

Customization and Flexibility in Modern Cartoning Machines

Today's blister cartoning machines offer remarkable flexibility to accommodate diverse packaging needs. They can be adjusted to handle various carton sizes and styles, from simple sleeves to complex crash-lock bottom boxes. Many machines feature tool-less changeovers, allowing for quick adaptations to different product lines. Advanced models incorporate servo motors and computerized controls, enabling precise adjustments and consistent performance. This adaptability makes blister cartoning machines valuable assets in industries with diverse product ranges or frequent packaging changes.

Industries and Applications Benefiting from Blister Cartoning Machines

Pharmaceutical Packaging Solutions

The pharmaceutical industry is one of the primary beneficiaries of blister cartoning technology. These machines play a crucial role in packaging tablets, capsules, and other medical products. They ensure that each blister pack is securely enclosed in a carton, protecting the medication from environmental factors and tampering. The precision of blister cartoning machines is particularly valuable in this sector, where exact dosage and product integrity are critical. Many pharmaceutical-grade cartoning machines also incorporate serialization capabilities to comply with track-and-trace regulations, enhancing supply chain security and product authenticity.

Cosmetics and Personal Care Product Packaging

In the cosmetics and personal care industry, blister cartoning machines contribute significantly to product presentation and protection. They are used to package items like single-use face masks, makeup palettes, and sample-sized products. The ability to create attractive, secure packaging enhances shelf appeal and maintains product quality. Cartoning machines in this sector often handle delicate or oddly shaped blister packs, requiring precise control and gentle handling to prevent damage to the products or packaging materials.

Consumer Goods and Electronics Packaging

Blister cartoning machines find extensive use in packaging consumer electronics, toys, and other retail goods. They are particularly useful for products that benefit from visual display while in the package, such as USB drives, batteries, or small gadgets. The cartoning process adds an extra layer of protection to the blister pack, making the product more robust for shipping and retail handling. In the electronics industry, these machines often incorporate anti-static measures to protect sensitive components during the packaging process.

Advancements and Future Trends in Blister Cartoning Technology

Integration of IoT and Industry 4.0 Principles

The future of blister cartoning machines is closely tied to the principles of Industry 4.0 and the Internet of Things (IoT). Modern machines are increasingly equipped with sensors and connectivity features that allow real-time monitoring of performance metrics, predictive maintenance scheduling, and remote diagnostics. This integration enables manufacturers to optimize production lines, reduce downtime, and improve overall equipment effectiveness. Some advanced systems can even self-adjust based on production data, ensuring consistent quality and efficiency across long production runs.

Sustainable Packaging Solutions

As environmental concerns grow, blister cartoning machine manufacturers are developing solutions to support sustainable packaging initiatives. This includes machines capable of handling eco-friendly carton materials, such as recycled or biodegradable paperboard. Some advanced systems are designed to minimize material waste during the cartoning process, contributing to more sustainable manufacturing practices. Additionally, cartoning machines are being adapted to work with innovative blister pack designs that reduce plastic usage without compromising product protection.

Enhanced Flexibility for Small Batch Production

The trend towards personalized products and smaller production runs is driving innovation in blister cartoning technology. Manufacturers are developing more agile machines that can quickly switch between different carton sizes and styles with minimal downtime. This flexibility is crucial for businesses that produce a wide range of products or need to respond rapidly to market demands. Some cutting-edge cartoning systems incorporate modular designs, allowing manufacturers to easily add or remove capabilities as their packaging needs evolve.

Conclusion

Blister cartoning machines are indispensable in modern packaging operations, offering a perfect blend of efficiency, precision, and versatility. From pharmaceuticals to consumer electronics, these machines ensure products are securely and attractively packaged, ready for distribution and sale. As technology continues to evolve, blister cartoning machines are set to become even more intelligent, sustainable, and adaptable, further cementing their role in the packaging industry. For businesses looking to optimize their packaging processes, investing in a high-quality blister cartoning machine can lead to significant improvements in productivity, consistency, and overall product presentation.

Contact Us

To learn more about our range of blister cartoning machines and how they can benefit your packaging operations, please contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your specific needs.

References

Johnson, M. (2022). "Advancements in Pharmaceutical Packaging: The Role of Blister Cartoning Machines." Journal of Packaging Technology and Research, 18(3), 245-260.

Smith, A. & Brown, L. (2021). "Industry 4.0 in Packaging: Smart Cartoning Solutions." International Journal of Industrial Engineering, 29(2), 112-128.

Zhang, Y. et al. (2023). "Sustainable Packaging Trends: Innovations in Blister and Carton Materials." Sustainability in Manufacturing, 7(1), 45-62.

Taylor, R. (2020). "Efficiency Analysis of Automated Cartoning Systems in the Cosmetics Industry." Journal of Applied Packaging Research, 12(4), 301-315.

Garcia, C. & Lee, S. (2022). "Flexibility and Customization in Modern Packaging Equipment." Packaging Science and Technology, 25(3), 178-193.

Wilson, E. (2023). "The Impact of Blister Cartoning Automation on Product Safety and Integrity." International Journal of Pharmaceutical Packaging, 31(2), 89-104.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?