What is an Automatic Cartoning Machine Used For?

An automatic cartoning machine, also known as an automatic cartoner, is a versatile packaging solution designed to streamline the process of encasing products in cartons or boxes. These sophisticated machines are indispensable in various industries, including pharmaceuticals, cosmetics, food, and consumer goods. Automatic cartoning machines efficiently handle a wide range of products, from blister packs and pillow pouches to tubes, bottles, vials, and even irregularly shaped items like lotions, lipsticks, and soaps. By automating the cartoning process, these machines significantly enhance production speed, improve packaging consistency, and reduce labor costs. The continuous transmission system, synchronized pushing mechanism, and rotary suction box device ensure smooth operation with minimal noise, making automatic cartoners an essential component in modern packaging lines.

The Versatility and Applications of Automatic Cartoning Machines Pharmaceutical Packaging Solutions

In the pharmaceutical industry, precision and hygiene are paramount. Automatic cartoning machines excel in handling delicate medical products such as blister packs, vials, and ampoules. These machines can be configured to meet stringent cGMP requirements, ensuring that medications are packaged in a sterile environment. The ability to integrate tamper-evident features and print batch numbers or expiration dates directly on cartons further enhances product safety and traceability.

Cosmetics and Personal Care Products

The cosmetics sector benefits greatly from the flexibility of automatic cartoners. These machines can deftly handle a variety of product shapes and sizes, from slim lipstick tubes to bulky lotion bottles. The precision of modern cartoning equipment ensures that high-value cosmetic items are packaged attractively and securely, maintaining brand aesthetics while protecting the product during transit and storage.

Food and Beverage Packaging

In the food industry, automatic cartoning machines play a crucial role in packaging everything from tea bags to frozen meals. The high-speed capabilities of these machines are particularly valuable in the fast-paced food production environment. Advanced cartoners can be equipped with features like modified atmosphere packaging (MAP) systems, which extend the shelf life of perishable foods by altering the composition of air inside the carton.

Key Features and Advantages of Modern Automatic Cartoners

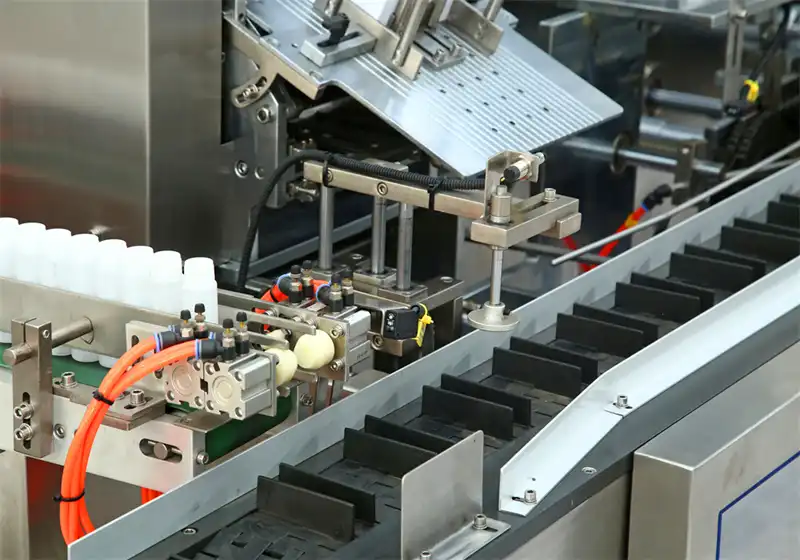

Continuous Transmission System

The continuous transmission system is a hallmark of advanced automatic cartoning machines. This feature ensures a smooth, uninterrupted flow of products through the packaging process. By eliminating start-stop motions, the machine achieves higher speeds and reduces wear on mechanical components. The result is increased productivity and lower maintenance requirements, contributing to a more efficient packaging operation.

Synchronization and Precision

Modern automatic cartoners utilize sophisticated synchronization mechanisms to coordinate various elements of the packaging process. The synchronized pushing system works in tandem with product infeed, carton erection, and sealing operations. This precise timing minimizes jams and ensures that each product is accurately placed within its carton. The harmony of these synchronized movements contributes to the machine's ability to maintain high speeds without compromising packaging quality.

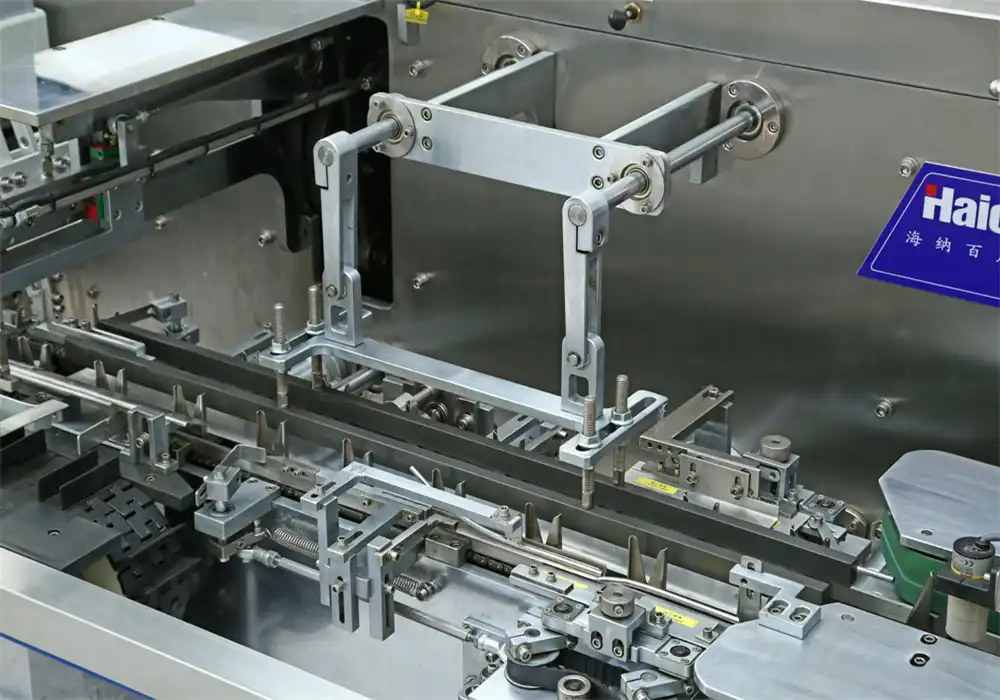

Rotary Suction Box Technology

The incorporation of rotary suction box devices in automatic cartoning machines represents a significant advancement in carton handling. This technology uses vacuum suction to grip and manipulate cartons securely throughout the packaging process. The rotary motion allows for smooth transitions between stations, reducing the likelihood of carton deformation or misalignment. This innovative approach not only enhances speed but also improves the overall reliability of the cartoning operation.

Optimizing Packaging Operations with Automatic Cartoning Machines

Enhancing Production Efficiency

Implementing an automatic cartoning machine can dramatically increase packaging line efficiency. These machines are capable of operating at speeds that far surpass manual cartoning methods. With some models achieving outputs of several hundred cartons per minute, production capacity can be significantly expanded without a proportional increase in labor costs. The consistency of machine operation also reduces variability in packaging quality, leading to fewer rejects and less product waste.

Improving Workplace Ergonomics

The balcony-type pushback layout commonly found in modern automatic cartoning machines is designed with operator convenience in mind. This configuration provides easy access to critical machine components, simplifying maintenance and troubleshooting procedures. The elevated design also contributes to a cleaner working environment by preventing debris accumulation around the machine base. These ergonomic improvements not only enhance operator comfort but also contribute to increased uptime and overall equipment effectiveness.

Customization and Flexibility

One of the most valuable aspects of automatic cartoning machines is their adaptability to different product types and packaging formats. Many models offer tool-less changeovers, allowing production lines to switch between different carton sizes or product types with minimal downtime. This flexibility is particularly beneficial for contract packagers or manufacturers with diverse product lines. Advanced cartoners can also be integrated with vision systems for quality control or fitted with coding and marking devices for real-time product identification.

Conclusion

Automatic cartoning machines are indispensable tools in modern packaging operations, offering a perfect blend of speed, precision, and versatility. From pharmaceuticals to food products, these machines streamline the packaging process, ensuring consistent quality while significantly boosting productivity. The continuous transmission systems, synchronized operations, and ergonomic designs of today's cartoners make them an invaluable asset for businesses looking to optimize their packaging lines. As packaging technology continues to evolve, automatic cartoning machines will undoubtedly play a crucial role in shaping the future of efficient and innovative product packaging solutions.

Contact Us

For more information on how an automatic cartoning machine can revolutionize your packaging process, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your specific needs.

References

Smith, J. (2022). Advanced Packaging Technologies in the Pharmaceutical Industry. Journal of Pharmaceutical Innovation, 15(3), 178-192.

Johnson, A. & Lee, S. (2021). Automation Trends in Food Packaging: A Comprehensive Review. Food Engineering Reviews, 13(2), 245-260.

Brown, T. (2023). Ergonomics in Packaging Equipment Design: Improving Operator Efficiency and Safety. International Journal of Industrial Ergonomics, 85, 103232.

Garcia, M. et al. (2020). Sustainability in Packaging Machinery: Energy Efficiency and Waste Reduction. Sustainability, 12(18), 7433.

Wilson, R. (2022). The Impact of Industry 4.0 on Packaging Operations. Packaging Technology and Science, 35(4), 217-231.

Zhang, L. & Chen, H. (2021). Advancements in Carton Sealing Technologies for Enhanced Product Protection. Journal of Applied Packaging Research, 13(3), 1-15.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?