What Makes a Blister Packing Machine GMP Compliant?

A blister packaging machine achieves GMP compliance through a combination of design features, operational controls, and quality assurance measures. GMP-compliant machines are constructed with food-grade materials, incorporate cleanroom-compatible designs, and feature robust documentation systems. They ensure consistent product quality, minimize contamination risks, and facilitate thorough cleaning and sanitization. These machines also integrate advanced process controls, error prevention mechanisms, and traceability features. By adhering to stringent manufacturing standards and regulatory requirements, GMP-compliant blister packaging machines safeguard product integrity, enhance patient safety, and meet the rigorous demands of pharmaceutical and healthcare industries worldwide.

Key Design Features of GMP-Compliant Blister Packaging Machines

Material Selection and Construction

GMP-compliant blister packaging machines are built with an emphasis on hygiene, durability, and regulatory adherence. They are primarily constructed from high-grade, corrosion-resistant stainless steel, which offers excellent longevity and prevents chemical interactions with packaging materials or products. Polished, non-porous surfaces reduce microbial adhesion and make cleaning and sanitization more effective. The design intentionally avoids crevices and sharp angles where contaminants could hide, ensuring the entire machine can be thoroughly cleaned to maintain the strict cleanliness required in pharmaceutical and cosmetic environments.

Cleanroom Compatibility

Blister packaging equipment designed for GMP compliance must function efficiently within cleanroom settings. These machines often include features that support contamination control, such as fully enclosed designs, laminar airflow capabilities, and compatibility with HEPA filtration systems. Positive air pressure control may also be integrated to prevent the ingress of contaminants. These features help maintain the sterile conditions required for sensitive product packaging, ensuring that the production environment meets stringent air quality standards and reducing the risk of cross-contamination during packaging.

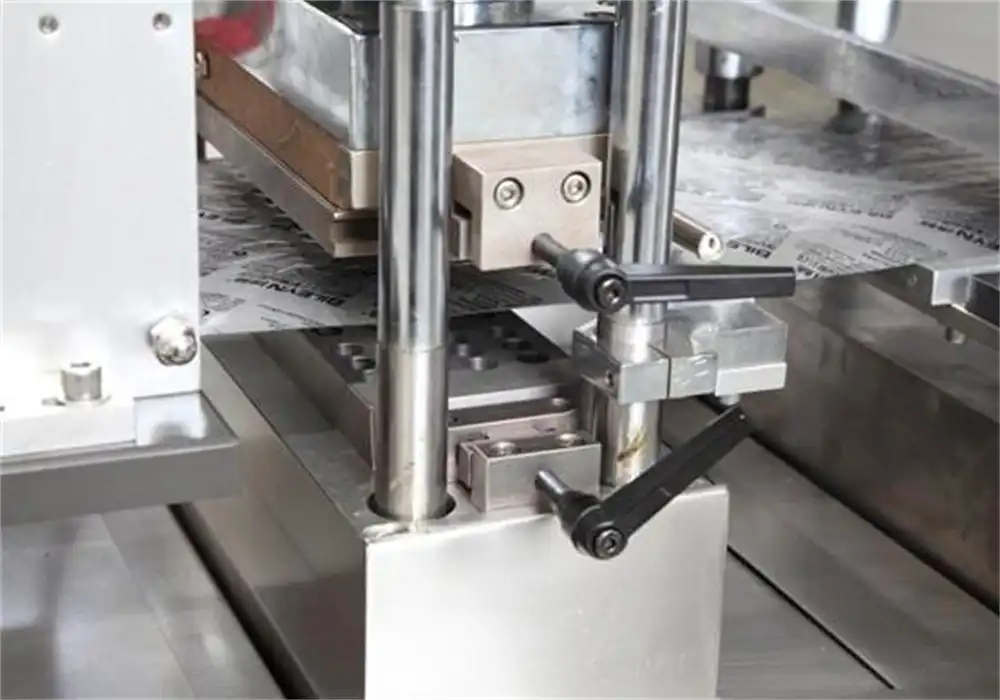

Ergonomic and User-Friendly Design

Operator interaction is a key factor in GMP compliance, so blister packaging machines are designed to be both ergonomic and intuitive. Adjustable touchscreens, clearly labeled controls, and easily accessible components help streamline operation and reduce fatigue. Maintenance areas are typically tool-free or quick-release, minimizing downtime and human error. Transparent safety doors and well-lit interiors improve visibility during inspection or adjustments. These user-focused features enhance productivity, minimize risk, and support accurate, repeatable operation - crucial elements for maintaining Good Manufacturing Practice standards.

Operational Controls and Quality Assurance Measures

Advanced Process Control Systems

Modern GMP-compliant blister packaging machines come equipped with advanced process control technologies designed to enhance precision and consistency. Utilizing programmable logic controllers (PLCs) and human-machine interfaces (HMIs), these systems manage key variables like forming temperature, sealing pressure, and dwell time with high accuracy. Operators benefit from real-time data visualization, alarms for deviation, and automatic adjustment features. Continuous data logging allows for better process validation and troubleshooting, ensuring every batch meets strict quality standards and complies with regulatory expectations.

In-Process Quality Checks

To uphold GMP standards, blister packaging machines include integrated in-process quality assurance mechanisms. These typically involve high-resolution vision inspection systems that detect misfeeds, incorrect labeling, or material defects. Weight checking stations confirm the presence and accuracy of product dosing, while advanced leak detection technologies verify the airtightness and integrity of each package. By addressing quality issues immediately during production, these systems minimize waste, prevent product recalls, and ensure that only fully compliant packages proceed through the production line.

Validation and Calibration Protocols

Validation and calibration are fundamental for ensuring that GMP-compliant blister packaging machines maintain reliable and repeatable performance. These machines are engineered for ease of validation, offering built-in calibration ports, standardized protocols, and comprehensive documentation packages. Periodic calibration of sensors and control systems ensures adherence to exact process specifications. Additionally, validation activities - such as Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) - help verify that the equipment consistently produces products that meet predefined quality criteria, supporting regulatory compliance and operational excellence.

Documentation and Traceability Features

Comprehensive Documentation Systems

Good Manufacturing Practice (GMP) compliance requires meticulous record-keeping throughout the packaging process. Modern blister packaging machines support this requirement by offering integrated documentation systems that automatically record critical parameters such as production speeds, sealing temperatures, and operator interventions. These digital logs reduce the risk of human error and allow for easier access and retrieval of information. When linked with enterprise resource planning (ERP) or quality management systems, they ensure real-time data synchronization and full transparency across the manufacturing and quality assurance environments.

Audit Trail and Data Integrity

Ensuring data integrity is crucial for meeting GMP standards in pharmaceutical packaging. Blister packaging equipment today includes advanced audit trail functionalities that log all user activities, from machine setup to parameter changes. Features like multi-level user authentication, role-based access control, and secure time-stamped electronic signatures help prevent unauthorized changes and ensure accountability. Additionally, tamper-evident data storage mechanisms safeguard the integrity of recorded information, providing regulators and auditors with a reliable trail of evidence during inspections or quality investigations.

Batch Tracking and Serialization

Serialization is a key component in modern GMP-compliant blister packaging machines, offering precise product tracking through unique codes assigned to each package. These codes allow manufacturers to trace each unit back to its production batch, significantly simplifying recall management and improving supply chain security. Advanced systems integrate seamlessly with centralized databases and national traceability networks, enabling end-to-end visibility. This high level of traceability not only supports regulatory compliance but also strengthens consumer safety and brand protection across global markets.

conclusion

GMP compliance in blister packaging machines is achieved through a holistic approach that encompasses design, operation, and documentation. These machines are built with high-quality materials, feature cleanroom-compatible designs, and incorporate advanced process controls. They prioritize product quality and safety through in-process checks and validation protocols. Comprehensive documentation systems and traceability features further ensure adherence to GMP standards. By investing in GMP-compliant blister packaging equipment, pharmaceutical manufacturers can ensure product integrity, meet regulatory requirements, and maintain consumer trust in an increasingly demanding market.

Contact Us

For more information about our GMP-compliant blister packaging machines and other packaging solutions, please contact us at [email protected]. Our team of experts is ready to assist you in finding the perfect packaging solution for your specific needs.

References

Johnson, A. (2022). GMP Compliance in Pharmaceutical Packaging: A Comprehensive Guide.

Smith, B., & Brown, C. (2021). Advances in Blister Packaging Technology for the Pharmaceutical Industry.

World Health Organization. (2020). Good Manufacturing Practices for Pharmaceutical Products: Main Principles.

European Medicines Agency. (2023). Guidelines on Good Manufacturing Practice Specific to Advanced Therapy Medicinal Products.

U.S. Food and Drug Administration. (2022). Current Good Manufacturing Practice (CGMP) Regulations.

International Society for Pharmaceutical Engineering. (2021). ISPE Good Practice Guide: Process Validation.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?