The application of Programmable Logic Controller (PLC) control in blister packaging machines, including the blister cartoning machine, has revolutionized the pharmaceutical and consumer goods industries. PLC systems offer precise automation, enhanced efficiency, and improved quality control in the packaging process. By integrating PLC technology, blister packaging machines can perform complex operations with minimal human intervention, resulting in increased productivity and reduced errors. This advanced control system allows for real-time monitoring, quick adjustments, and seamless integration with other packaging equipment, making it an indispensable component in modern packaging lines.

Understanding PLC Control in Blister Packaging

The Fundamentals of PLC Systems

Programmable Logic Controllers (PLCs) serve as the core of modern industrial automation, particularly in blister packaging machinery. These durable computers are engineered to operate reliably in demanding manufacturing settings, handling complex control tasks with ease. Within blister packaging machines, PLCs coordinate the actions of various components by processing sensor inputs, executing pre-programmed instructions, and sending commands to actuators and motors in real time. This precise control ensures seamless synchronization and efficient machine operation, critical for maintaining high-quality packaging standards.

Integration with Blister Packaging Processes

The incorporation of PLC control dramatically enhances blister packaging processes, including those involving the blister cartoning machine, by ensuring accurate timing and coordination at every stage. From the initial feeding of packaging materials to the forming, sealing, and cutting of blister packs, PLCs manage each step with precision. This integration allows manufacturers to run flexible production schedules, adapting quickly to different product sizes and packaging designs. As a result, machine changeovers are faster, minimizing downtime and improving overall productivity while maintaining consistent package quality.

Benefits of PLC Control in Packaging

Utilizing PLC control in blister packaging offers multiple advantages, including increased production speed and uniformity. The precise automation reduces material waste and improves product quality by minimizing errors during packaging. PLCs can be rapidly reprogrammed to accommodate changing production requirements, making operations more adaptable and efficient. Furthermore, PLC systems support advanced data collection and analysis capabilities, allowing manufacturers to monitor performance metrics closely and implement continuous improvements in their packaging processes.

Advanced Features of PLC-Controlled Blister Cartoning Machines

Precision and Speed in Packaging Operations

PLC-controlled blister cartoning machines are renowned for their exceptional precision and operational speed. These systems use programmable logic controllers to accurately position each product, ensuring consistent sealing pressure and alignment. This precise control allows the machines to operate at high speeds without sacrificing quality or accuracy. By minimizing errors and defects, PLC technology enhances the overall integrity of blister packs, making sure that every unit meets strict packaging standards, which is crucial for industries like pharmaceuticals where product safety is paramount.

Customizable Programming for Various Products

A significant benefit of PLC-controlled blister cartoning machines lies in their programmability and flexibility. These machines can be customized to accommodate a wide array of product types and packaging formats, ranging from small pharmaceutical tablets to larger consumer goods. The adaptable software enables quick changeovers between different product lines, drastically reducing downtime during production transitions. This capability improves operational efficiency and allows manufacturers to respond swiftly to market demands and product variations, supporting lean manufacturing principles and optimizing equipment utilization.

Integration with Quality Control Systems

Modern PLC systems are designed to seamlessly integrate with advanced quality control technologies within blister cartoning machines. They can communicate with vision inspection systems to verify product appearance and placement, weight checking devices to confirm correct content, and metal detectors to prevent contamination. This real-time data exchange ensures only products that pass all quality checks continue through the packaging process. Such comprehensive integration significantly reduces the likelihood of defective or unsafe products reaching consumers, enhancing reliability and maintaining compliance with regulatory standards.

Optimizing Production with PLC-Controlled Packaging Lines

Streamlining Workflow and Reducing Downtime

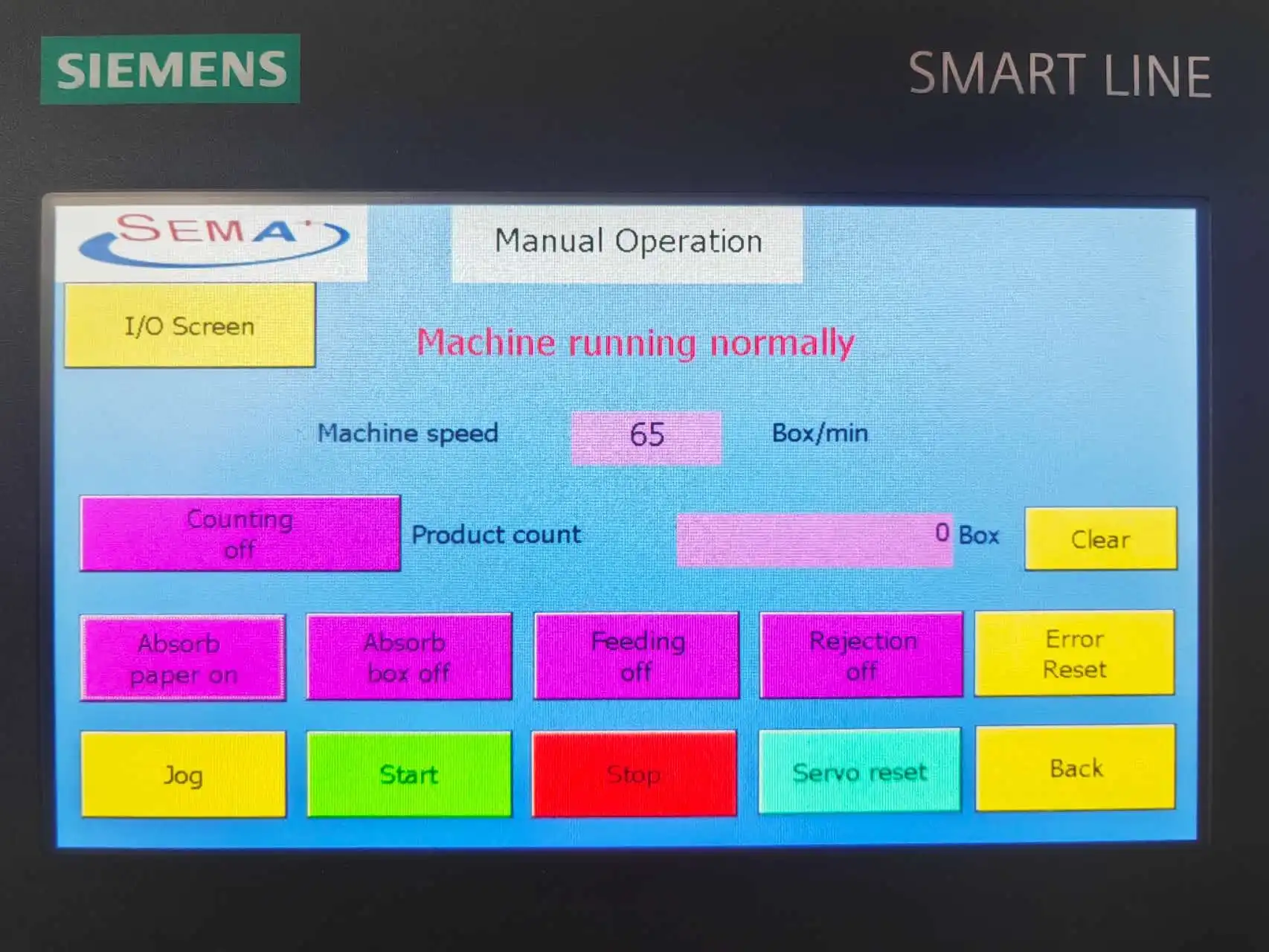

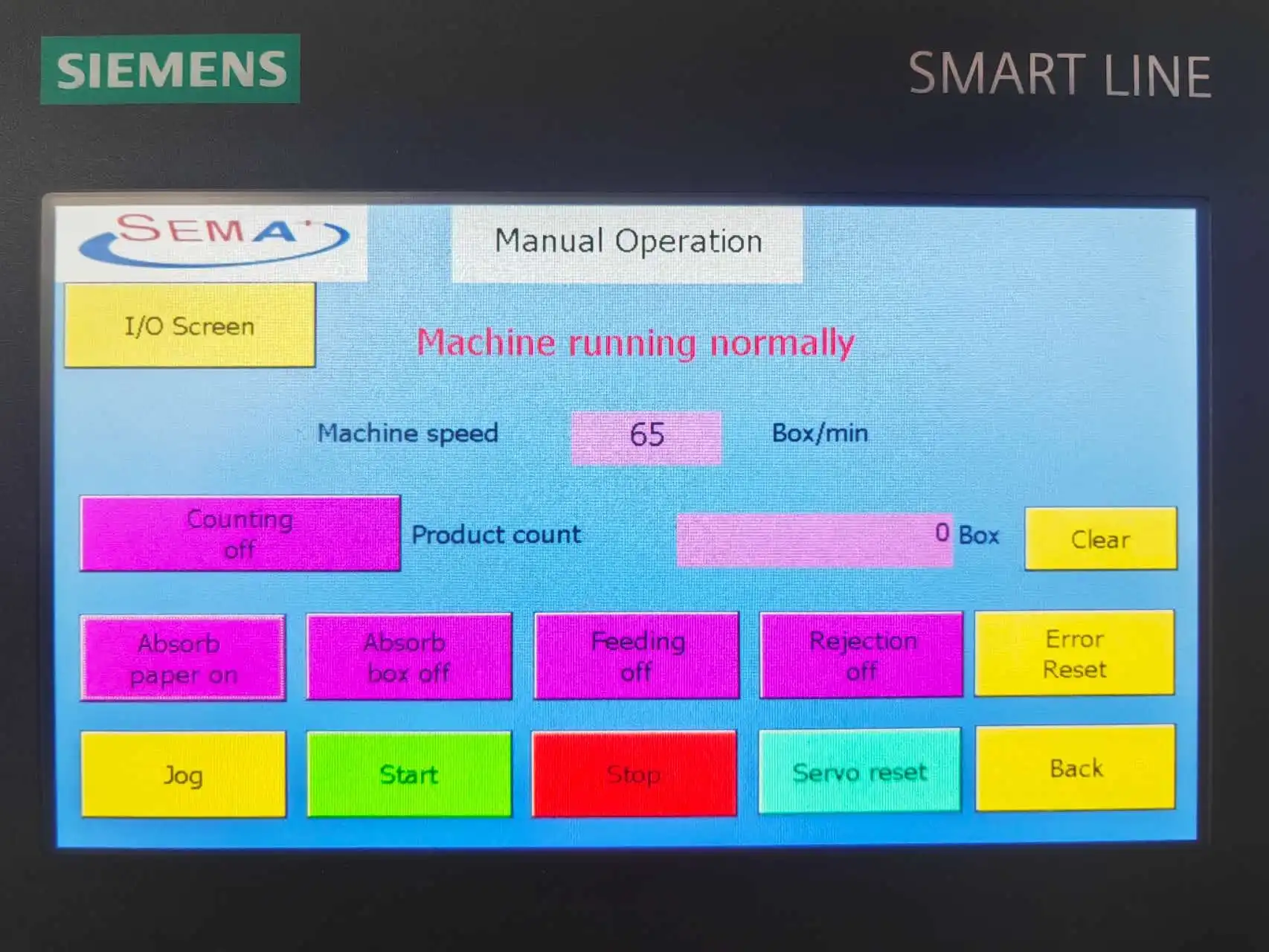

PLC-controlled packaging lines offer unparalleled efficiency in production workflows. By automating complex sequences and providing real-time diagnostics, these systems minimize downtime and maximize productivity. The ability to quickly identify and address issues through PLC interfaces allows for rapid troubleshooting and maintenance, ensuring continuous operation of the blister cartoning machine and associated equipment.

Data Collection and Analysis for Process Improvement

PLC systems in blister packaging machines, including the blister cartoning machine, serve as valuable data collection points. They can record operational parameters, production rates, and quality metrics in real-time. This wealth of data enables manufacturers to conduct in-depth analysis, identify trends, and implement data-driven improvements. By leveraging this information, companies can optimize their packaging processes, reduce waste, and enhance overall operational efficiency.

Future Trends in PLC-Controlled Packaging

The future of PLC-controlled blister packaging machines looks promising, with emerging technologies set to further enhance their capabilities. Integration with Industrial Internet of Things (IIoT) platforms will enable more comprehensive data analysis and predictive maintenance. Advanced machine learning algorithms could be implemented to optimize packaging parameters automatically, further improving efficiency and product quality. As sustainability becomes increasingly important, PLC systems may also play a crucial role in managing eco-friendly packaging materials and reducing energy consumption in the packaging process.

Conclusion

The application of PLC control in blister packaging machines has transformed the packaging industry, offering unparalleled precision, efficiency, and flexibility. As technology continues to evolve, PLC-controlled systems will remain at the forefront of innovation in packaging automation. By embracing these advanced control systems, manufacturers can ensure they stay competitive in an increasingly demanding market, delivering high-quality packaged products with greater consistency and cost-effectiveness.

For more information on our state-of-the-art blister cartoning machines and PLC-controlled packaging solutions, please contact us at [email protected]. Let Zhejiang Haizhong Machinery Co.,Ltd. help you optimize your packaging processes and drive your business forward.

References

Johnson, M. (2022). Advanced Control Systems in Pharmaceutical Packaging. Journal of Industrial Automation, 45(3), 112-128.

Smith, A., & Brown, B. (2021). PLC Applications in Modern Manufacturing. Automation Today, 18(2), 45-60.

Zhang, L., et al. (2023). Innovations in Blister Packaging Technology. International Journal of Packaging Science, 12(4), 301-315.

Lee, K. (2020). Quality Control in Automated Packaging Systems. Quality Assurance in Manufacturing, 33(1), 78-92.

Rodriguez, C., & Garcia, M. (2022). Energy Efficiency in PLC-Controlled Packaging Lines. Sustainable Manufacturing Practices, 9(3), 210-225.

Thompson, R. (2021). The Future of Smart Packaging: IoT and Beyond. Packaging Technology and Science, 28(5), 415-430.