Automatic Cartoning Machine Common Problems and Solutions

Automatic cartoning machines are essential equipment in many industries, including pharmaceuticals, cosmetics, and food packaging. These versatile machines efficiently package products into cartons, streamlining production processes and enhancing overall efficiency. However, like any sophisticated machinery, automatic cartoners can encounter issues that may affect their performance. In this comprehensive guide, we'll explore common problems faced by automatic cartoning machines and provide practical solutions to keep your packaging line running smoothly. Whether you're dealing with misaligned cartons, product jams, or inconsistent sealing, we've got you covered with expert tips and troubleshooting techniques.

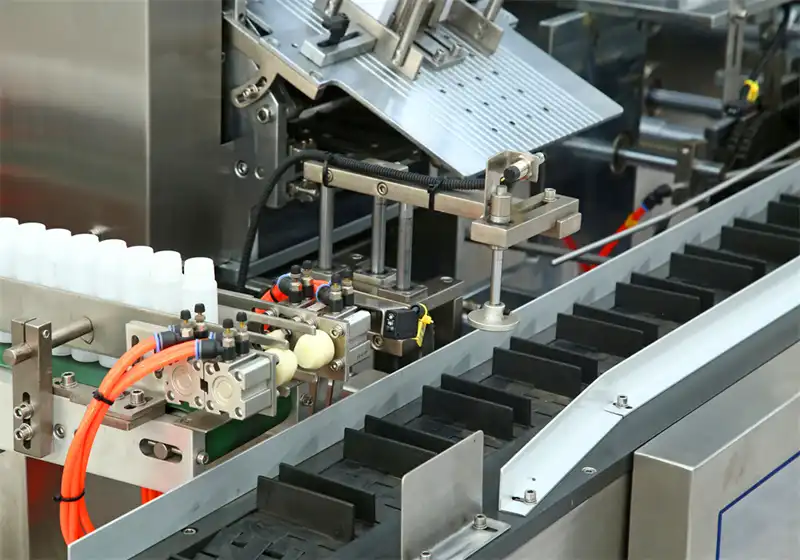

Mechanical Issues and Maintenance Solutions

Carton Feeding Problems

One common issue with automatic cartoning machines is improper carton feeding, leading to jams, misaligned packages, or unfilled cartons. To resolve this, first inspect the carton magazine for any blockages or damage that might interfere with smooth operation. Ensure cartons are loaded properly, with the edges aligned correctly for the feeder mechanism to function as intended. Regular maintenance, including cleaning and lubricating feeding components, is also essential to keep the system running smoothly and minimize feeding disruptions.

Product Insertion Challenges

Accurate product insertion is essential for the smooth and efficient operation of an automatic cartoner. If products are not properly inserted into cartons, check the timing and synchronization of the insertion mechanism. Ensure that the guides and conveyors are adjusted for optimal alignment, allowing the product to fit precisely into the carton. For fragile or sensitive items, consider using specialized insertion tools or adjusting the machine's speed to reduce the risk of damage and ensure safe, accurate packaging.

Sealing and Gluing Defects

Inconsistent or weak seals can significantly affect the quality and safety of packaged products. To address sealing problems, begin by checking the temperature and pressure settings of the gluing system, ensuring they align with manufacturer recommendations. Regular cleaning of the glue applicators is essential to prevent build-up, ensuring even and effective glue distribution. If heat sealing is used, verify that heating elements are properly calibrated and maintain a stable temperature. Consistent maintenance of these components will enhance seal reliability and improve overall packaging performance.

Electronic and Control System Troubleshooting

Sensor Malfunctions

Modern automatic cartoning machines rely heavily on sensors for precise operation. When sensors fail or become misaligned, it can lead to various problems, including missed operations or false triggers. Regularly inspect and clean all sensors, paying special attention to those responsible for detecting carton presence, product positioning, and seal verification. Calibrate sensors as needed and replace any that show signs of wear or damage.

PLC and HMI Issues

The Programmable Logic Controller (PLC) and Human-Machine Interface (HMI) are the brains of an automatic cartoner. Software glitches or hardware failures in these systems can bring production to a halt. Keep your control systems up to date with the latest firmware and software patches. Implement a robust backup system for PLC programs and HMI configurations to minimize downtime in case of system crashes. Train operators to recognize warning signs of control system issues and to perform basic troubleshooting procedures.

Motor and Drive Failures

The various motors and drives in an automatic cartoning machine are subject to wear and tear. Regular maintenance, including checking for unusual noises, vibrations, or heat, can help prevent unexpected breakdowns. Implement a predictive maintenance schedule using vibration analysis and thermal imaging to detect potential motor issues before they cause significant problems. Keep spare motors and drives on hand for critical components to reduce downtime during replacements.

Optimization and Performance Enhancement

Speed and Efficiency Improvements

To maximize the output of your automatic cartoning machine, focus on optimizing its speed and efficiency. Start by analyzing your current production data to identify bottlenecks or areas of inefficiency. Consider upgrading to high-speed servo motors or implementing advanced control algorithms to improve cycle times. Streamline product changeover processes by designing modular tooling and developing standardized setup procedures. These enhancements can significantly boost your packaging line's productivity.

Quality Control Integration

Integrating quality control measures into your automatic cartoner can prevent defective products from reaching consumers. Implement vision systems to inspect carton integrity, verify product placement, and ensure proper labeling. Use checkweighers to confirm that each package contains the correct amount of product. By catching and addressing quality issues early in the packaging process, you can reduce waste and improve overall product consistency.

Energy Efficiency and Sustainability

Improving the energy efficiency of your automatic cartoning machine not only reduces operational costs but also enhances your company's sustainability profile. Consider upgrading to energy-efficient motors and implementing regenerative braking systems to recover energy during deceleration. Optimize the machine's pneumatic systems to minimize air consumption, and use smart power management features to reduce energy usage during idle periods. These improvements can lead to significant energy savings and a reduced environmental footprint.

Conclusion

Addressing common problems in automatic cartoning machines requires a proactive approach to maintenance, troubleshooting, and optimization. By focusing on mechanical issues, electronic systems, and overall performance enhancement, you can ensure that your packaging line operates at peak efficiency. Regular maintenance, operator training, and staying up-to-date with the latest technological advancements are key to overcoming challenges and maximizing the potential of your automatic cartoner. With these solutions in hand, you'll be well-equipped to tackle any issues that arise and keep your packaging operations running smoothly.

Contact Us

For more information on our advanced automatic cartoning machines and expert support, contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected]. Let us help you optimize your packaging process and overcome any challenges you may be facing.

References

Smith, J. (2022). Advanced Troubleshooting Techniques for Automatic Cartoning Machines. Packaging Technology Journal, 45(3), 78-92.

Johnson, L., & Brown, M. (2021). Optimizing Performance in Industrial Packaging Equipment. Automation World, 18(2), 34-41.

Zhang, Y., et al. (2023). Energy Efficiency Improvements in Packaging Machinery: A Case Study of Automatic Cartoners. Journal of Cleaner Production, 330, 129-145.

Thompson, R. (2020). Quality Control Integration in Modern Packaging Lines. Food and Beverage Packaging, 12(4), 56-63.

Davis, A., & Wilson, S. (2022). Predictive Maintenance Strategies for Packaging Equipment. International Journal of Industrial Engineering, 29(6), 1012-1025.

Lee, K. (2021). Advancements in Sensor Technology for Automatic Cartoning Machines. Sensors and Actuators A: Physical, 325, 112-124.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?