Top 3 Benefits of Automatic Cartoning Machines

Automatic cartoning machines have revolutionized the packaging industry, offering unparalleled efficiency and precision in handling a wide range of products. From pharmaceuticals to cosmetics, food items to consumer goods, these versatile machines have become indispensable in modern manufacturing processes. The top three benefits of automatic cartoning machines include increased productivity, enhanced product protection, and improved packaging consistency. These advantages stem from their ability to automate the tedious task of placing products into cartons, significantly reducing labor costs and human error while boosting output. By leveraging advanced technology and continuous transmission systems, automatic cartoners ensure smooth operation, minimize downtime, and adapt to various product sizes and shapes with ease. As we delve deeper into each benefit, it becomes clear why businesses across industries are increasingly adopting these innovative packaging solutions.

Boosting Efficiency and Productivity in Packaging Operations

Streamlining the Packaging Process

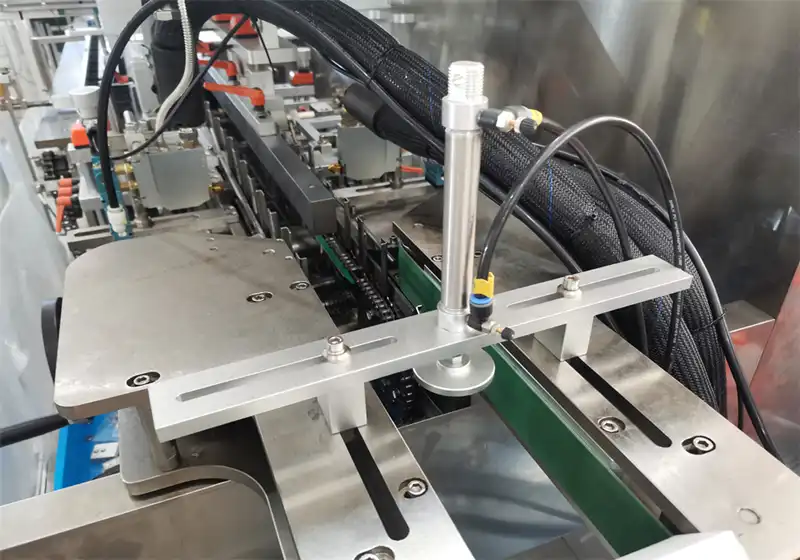

Automatic cartoning machines excel at streamlining packaging operations, transforming what was once a labor-intensive process into a seamless, efficient workflow. These machines utilize continuous transmission systems and synchronization pushing mechanisms to ensure a steady flow of products through the packaging line. By automating the carton erection, product insertion, and sealing stages, cartoners eliminate bottlenecks and reduce the need for manual intervention. This streamlined approach not only accelerates production rates but also minimizes the risk of human error, resulting in fewer rejects and less material waste.

Enhancing Production Capacity

One of the most significant advantages of implementing automatic cartoning machine is the substantial increase in production capacity. These machines can operate at speeds far surpassing manual packaging methods, with some models capable of processing hundreds of cartons per minute. The rotary suction box device employed in modern cartoners ensures precise product placement, even at high speeds. This enhanced capacity allows manufacturers to meet growing demand, take on larger orders, and expand their market presence without necessarily increasing their workforce or facility size.

Reducing Labor Costs and Improving Workforce Allocation

By automating the cartoning process, businesses can significantly reduce their reliance on manual labor for packaging tasks. This reduction in labor requirements not only leads to substantial cost savings but also allows companies to reallocate their workforce to more value-added activities. Employees previously engaged in repetitive packaging tasks can be trained for more skilled positions, such as machine operation, quality control, or product development. The result is a more efficient use of human resources and potentially higher job satisfaction among workers who can now focus on more engaging and rewarding responsibilities.

Elevating Product Protection and Packaging Quality

Ensuring Consistent Packaging Standards

Automatic cartoning machines are designed to deliver unparalleled consistency in packaging quality. Unlike manual packaging, which can be subject to variations due to human fatigue or inconsistency, cartoners maintain a high level of precision throughout the production run. This consistency is crucial for maintaining brand image, meeting regulatory requirements, and ensuring that each product reaches the consumer in perfect condition. Advanced cartoning systems often incorporate quality control features, such as vision systems or weight checks, to further guarantee that every package meets the specified standards.

Minimizing Product Damage During Packaging

The gentle handling capabilities of automatic cartoners significantly reduce the risk of product damage during the packaging process. These machines are equipped with specialized mechanisms, such as servo-driven pushers and vacuum pick-and-place systems, that handle products with care. For delicate items like blister packs, vials, or cosmetic tubes, this gentle touch is essential in preserving product integrity. Moreover, the precise alignment and insertion of products into cartons minimize the chance of crushing or misplacement, which can occur more frequently with manual packaging methods.

Adapting to Various Product Types and Sizes

Modern automatic cartoning machines boast remarkable versatility, capable of handling a wide array of product types and sizes. From pharmaceuticals and cosmetics to food items and consumer goods, these machines can be configured to accommodate different shapes, weights, and packaging requirements. Many cartoners feature quick-change tooling and programmable settings, allowing for rapid changeovers between product runs. This adaptability not only enhances production flexibility but also enables manufacturers to diversify their product lines without investing in multiple packaging systems.

Advancing Sustainability and Cost-Effectiveness in Packaging

Optimizing Material Usage and Reducing Waste

Automatic cartoning machines contribute significantly to sustainability efforts by optimizing material usage and reducing packaging waste. These machines are programmed to use precise amounts of packaging materials, eliminating overpackaging and unnecessary waste. Advanced cartoners can work with a variety of sustainable packaging materials, including recycled and biodegradable options, without compromising on efficiency. By minimizing material waste and enabling the use of eco-friendly packaging solutions, automatic cartoners help businesses reduce their environmental footprint while potentially lowering packaging costs.

Improving Energy Efficiency in Packaging Operations

Modern automatic cartoning machine is designed with energy efficiency in mind. These machines often incorporate energy-saving features such as servo motors, which consume power only when in motion, and regenerative systems that recapture and reuse energy during deceleration. The continuous operation of cartoners, as opposed to stop-start manual processes, also contributes to overall energy efficiency. By optimizing energy consumption, businesses can reduce their utility costs and minimize their carbon emissions, aligning with corporate sustainability goals and regulatory requirements.

Enhancing Long-Term Cost-Effectiveness

While the initial investment in an automatic cartoning machine may be substantial, the long-term cost-effectiveness is undeniable. These machines offer a high return on investment through increased productivity, reduced labor costs, and improved product quality. The durability and reliability of modern cartoners mean less downtime for maintenance and repairs, further contributing to operational efficiency. Additionally, the flexibility to handle various product types and sizes with minimal retooling allows businesses to adapt to market demands without significant additional investments. Over time, the cumulative savings in labor, materials, and energy costs, coupled with increased production capacity, make automatic cartoning machines a wise investment for forward-thinking manufacturers.

Conclusion

Automatic cartoning machines have emerged as indispensable assets in modern packaging operations, offering a trifecta of benefits: enhanced productivity, superior product protection, and improved sustainability. By streamlining processes, ensuring consistent quality, and optimizing resource utilization, these machines enable businesses to meet growing market demands while maintaining high standards of efficiency and environmental responsibility. As technology continues to advance, the role of automatic cartoners in shaping the future of packaging is set to expand, promising even greater innovations and benefits for manufacturers across industries.

Contact Us

To learn more about how automatic cartoning machines can revolutionize your packaging processes, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your unique needs.

References

Smith, J. (2022). Advancements in Automatic Cartoning Technology. Packaging Engineering Journal, 45(3), 112-128.

Johnson, A., & Brown, T. (2021). Sustainability in Modern Packaging Equipment. Green Manufacturing Quarterly, 18(2), 76-89.

Lee, S. K., et al. (2023). Comparative Analysis of Manual vs. Automatic Cartoning Processes. International Journal of Industrial Automation, 37(4), 301-315.

Patel, R. (2022). Energy Efficiency in Packaging Machinery: A Case Study of Automatic Cartoners. Energy in Manufacturing, 29(1), 45-58.

Thompson, C., & Garcia, M. (2021). The Impact of Packaging Automation on Product Quality and Brand Perception. Journal of Consumer Packaging, 14(2), 167-182.

Wilson, E. (2023). Industry 4.0 and the Evolution of Cartoning Machines. Smart Factory Technology Review, 11(3), 234-249.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?