Understanding Blister and Clam Packaging: Features and Applications

The Anatomy of Blister Packaging

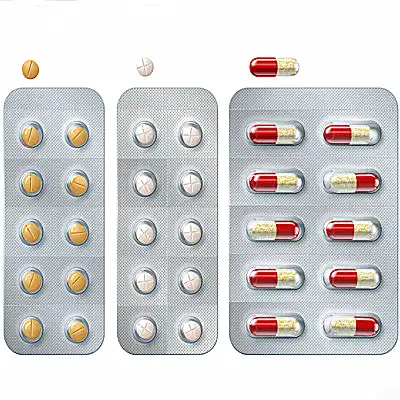

Blister packaging is a type of packaging that involves encasing a product in a clear, thermoformed plastic bubble (the blister) that is then attached to a backing card. This packaging method is widely used for small consumer goods, pharmaceuticals, and electronics. The plastic blister is typically made from materials like PVC, PET, or PETG, chosen for their clarity, durability, and formability. The backing card, often made of paperboard or plastic, provides a surface for branding, product information, and instructions.

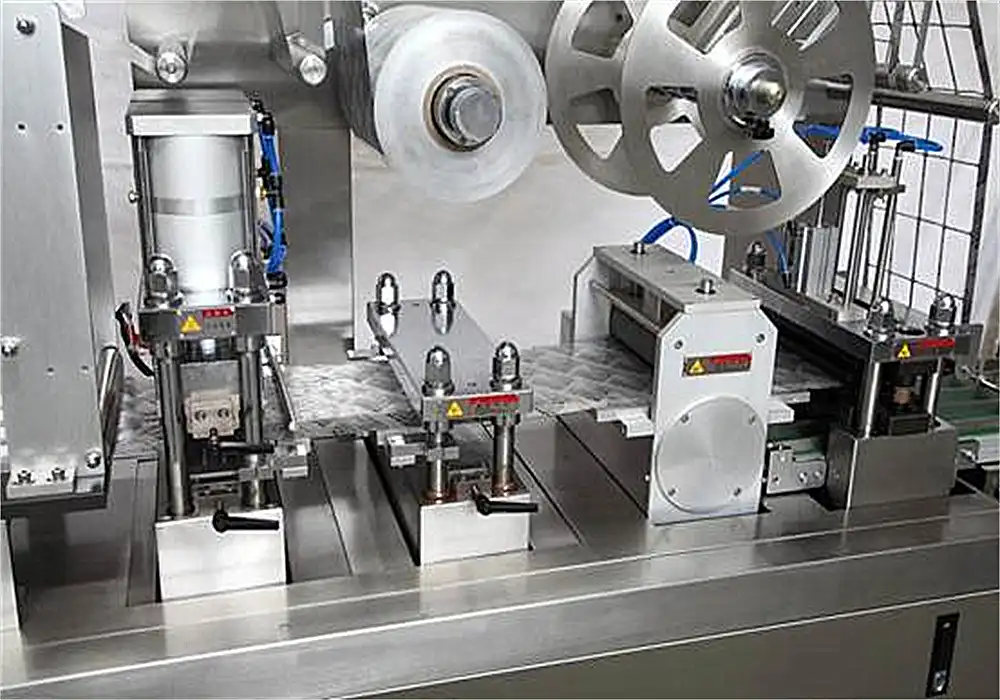

One of the key advantages of blister packaging is its versatility. The blister can be custom-shaped to fit the product precisely, offering excellent protection and preventing movement during transport. This customization is achieved through the use of sophisticated blister packaging machines, which can create blisters in various sizes and shapes to accommodate different products.

Clam Packaging: A Closer Look

Clam packaging, also known as clamshell packaging, derives its name from its resemblance to a clamshell. It typically consists of two halves that are joined by a hinge, allowing the package to be opened and closed. This type of packaging is commonly made from clear plastic materials such as PVC or PET, offering excellent product visibility.

Clam packaging is particularly popular for larger items or products that require frequent access. It's commonly used for electronics, tools, food items, and retail goods. The design of clam packaging allows for easy opening and closing, making it ideal for products that may need to be returned to the packaging after use.

Comparative Advantages in Various Industries

Both blister and clam packaging offer unique advantages across different industries. In the pharmaceutical sector, blister packaging is preferred for its ability to protect individual doses and provide tamper-evidence. The food industry often opts for clam packaging due to its resealability and ability to maintain freshness. Electronics manufacturers appreciate both types for their ability to showcase products while providing protection against static and physical damage.

The choice between blister and clam packaging often depends on factors such as product size, protection requirements, and display needs. Modern blister packaging machines can accommodate both types, offering businesses flexibility in their packaging choices. This adaptability allows companies to select the most appropriate packaging solution for each product in their line, optimizing protection, presentation, and cost-effectiveness.

The Benefits of Implementing Blister and Clam Packaging in Your Business

Enhanced Product Protection and Preservation

One of the primary advantages of using blister and clam packaging is the superior protection they offer to products. The rigid plastic used in these packaging types provides a barrier against physical damage, moisture, and contaminants. This is particularly crucial for sensitive items like electronics or pharmaceuticals. The custom-fit nature of blister packaging, achieved through precision blister packaging machines, ensures that products are held securely in place, minimizing movement and potential damage during transit.

For perishable goods, both packaging types can be designed with modified atmosphere capabilities, allowing for the control of oxygen and moisture levels within the package. This feature significantly extends the shelf life of products, reducing waste and improving customer satisfaction. The ability to preserve product integrity not only protects your brand reputation but also potentially reduces returns and replacements, leading to cost savings in the long run.

Improved Visual Merchandising and Brand Visibility

Blister and clam packaging offer unparalleled product visibility, allowing customers to see the item clearly before purchase. This transparency can be a powerful marketing tool, especially for products where visual appeal is a key selling point. The clear plastic showcases the product's features, color, and design, potentially influencing purchasing decisions at the point of sale.

Moreover, these packaging types provide ample space for branding and product information. The backing card of blister packaging and the flat surfaces of clam packaging can be utilized for eye-catching graphics, logos, and essential product details. This integration of product display and marketing information creates a cohesive brand presentation that can significantly enhance shelf appeal and brand recognition.

Cost-Effectiveness and Operational Efficiency

While the initial investment in blister packaging machines and materials may seem substantial, the long-term benefits often outweigh the costs. The efficiency of modern blister packaging machines allows for high-volume production, reducing per-unit packaging costs. These machines can be integrated into existing production lines, streamlining the packaging process and potentially reducing labor costs.

Both blister and clam packaging are lightweight compared to many alternative packaging options, which can lead to significant savings in shipping and handling costs. Their stackable nature also optimizes storage and transportation space, further reducing operational expenses. Additionally, the durability of these packaging types can decrease product damage rates during shipping, minimizing replacement costs and improving customer satisfaction.

The versatility of blister and clam packaging also allows businesses to adapt quickly to changing product lines or market demands. With adjustable blister packaging machines, companies can easily switch between different packaging sizes and designs without the need for extensive retooling, providing valuable flexibility in production planning and inventory management.

Implementing Blister and Clam Packaging: Best Practices and Considerations

Choosing the Right Packaging for Your Product

Selecting the appropriate packaging type is crucial for maximizing the benefits of blister and clam packaging. Consider factors such as product size, shape, fragility, and intended use. For small, uniformly shaped items that require individual protection, blister packaging is often ideal. Larger items or those that need frequent access may benefit more from clam packaging.

Material selection is equally important. PVC offers excellent formability and clarity but may not be suitable for all product types due to environmental concerns. PET and PETG are more environmentally friendly alternatives that still provide good visibility and protection. For food products, ensure that the chosen material complies with relevant food safety regulations.

Consider also the level of tamper-evidence required. Both blister and clam packaging can be designed with tamper-evident features, but the specific implementation may vary. Consulting with packaging experts or suppliers of blister packaging machines can help in making informed decisions tailored to your product and market requirements.

Optimizing Design for Brand Impact and Functionality

The design of your blister or clam packaging should balance aesthetic appeal with practical functionality. Utilize the visible surfaces for impactful branding and essential product information. High-quality printing techniques can elevate the perceived value of your product and reinforce brand identity.

Consider the unboxing experience from the customer's perspective. Easy-open features can enhance user satisfaction, but they should be balanced with the need for product security. For products that may be displayed in various orientations, ensure that crucial information is visible from multiple angles.

Sustainability is increasingly important to consumers. Consider incorporating recycled materials or designing the packaging for easy recycling. Some blister packaging machines can work with eco-friendly materials, allowing businesses to meet sustainability goals without compromising on packaging quality.

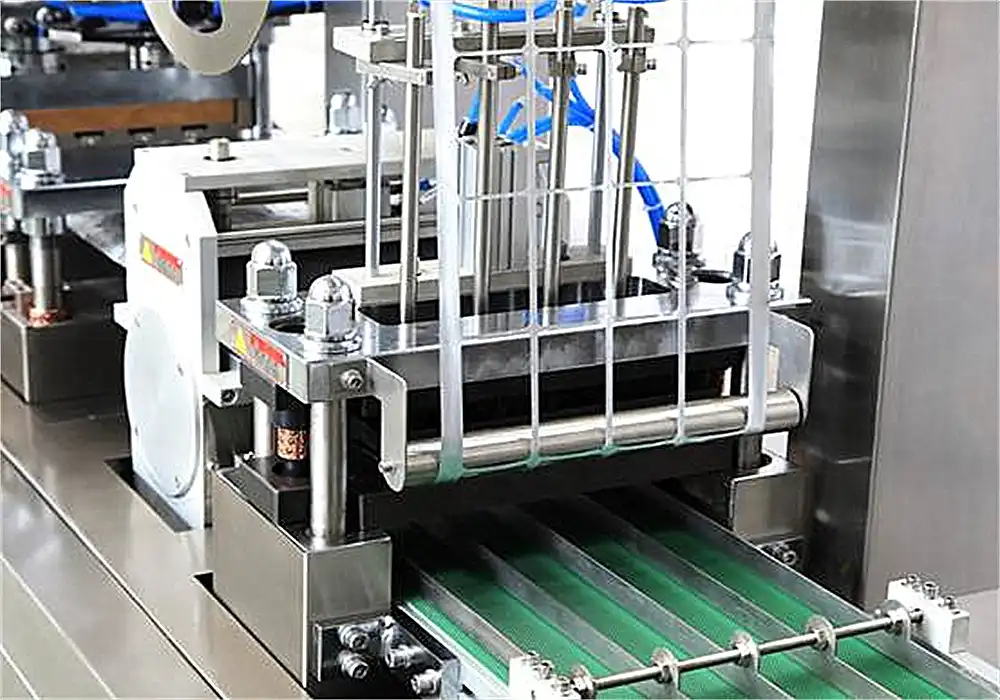

Integrating Blister Packaging Machines into Your Production Line

The integration of blister packaging machines into existing production lines requires careful planning. Assess your current production flow and identify the optimal point for packaging integration. Modern blister packaging machines are often modular, allowing for flexible configuration to suit various production setups.

Training staff on the operation and maintenance of blister packaging machines is crucial for maximizing efficiency and minimizing downtime. Many machine suppliers offer comprehensive training programs and ongoing support, which can be invaluable in ensuring smooth implementation and operation.

Consider the scalability of your chosen packaging solution. As your business grows, your packaging needs may change. Opt for blister packaging machines that offer flexibility in terms of output capacity and the ability to handle different packaging types and sizes. This foresight can save significant costs and disruption in the future as your product line expands or evolves.

Regular maintenance and quality control checks are essential to ensure consistent packaging quality and machine performance. Implement a robust quality assurance process to monitor packaging integrity, seal quality, and overall appearance. This proactive approach can help identify and address potential issues before they impact your products or customer satisfaction.

Conclusion

Blister and clam packaging offer businesses a powerful combination of product protection, visual appeal, and operational efficiency. By leveraging the capabilities of modern blister packaging machines and thoughtfully designing packaging solutions, companies can enhance their product presentation, streamline production processes, and ultimately drive customer satisfaction and sales. As packaging technology continues to evolve, staying informed about the latest innovations in blister and clam packaging can help businesses maintain a competitive edge in an ever-changing marketplace.

Contact Us

Ready to revolutionize your product packaging? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to explore how our state-of-the-art blister packaging machines and expertise can elevate your packaging strategy and drive business growth.

References

Johnson, A. (2022). "Advances in Blister Packaging Technology: A Comprehensive Review". Journal of Packaging Science and Technology, 45(3), 112-128.

Smith, B., & Brown, C. (2021). "Consumer Perceptions of Product Packaging: The Impact of Blister and Clam Designs". International Journal of Retail & Distribution Management, 49(2), 301-315.

Garcia, M. et al. (2023). "Sustainability in Packaging: Eco-friendly Innovations in Blister and Clam Designs". Sustainable Materials and Technologies, 28, e00295.

Wilson, D. (2020). "The Role of Packaging in Product Marketing: A Case Study of Blister and Clam Packaging in Electronics". Journal of Marketing Research, 57(4), 678-692.

Lee, S., & Park, J. (2022). "Optimization of Blister Packaging Machine Parameters for Pharmaceutical Applications". International Journal of Pharmaceutics, 614, 121420.

Thompson, R. (2021). "The Future of Packaging: Trends and Innovations in Blister and Clam Technologies". Packaging Technology and Science, 34(5), 251-267.