Understanding Blister Packaging Materials

Composition of Alu-Alu Blisters

Alu-Alu blisters are characterized by aluminum layers on both the forming and lidding sides, providing exceptional protective qualities. The forming film is typically a multi-layer laminate comprising polyamide, aluminum, and PVC, while the lidding consists of pure aluminum foil. This robust construction creates an almost impermeable barrier against moisture, oxygen, and light, making Alu-Alu blisters especially suitable for packaging highly moisture-sensitive and light-sensitive pharmaceutical products that require maximum preservation.

Structure of PVC Blisters

PVC blisters primarily use polyvinyl chloride as the forming film, combined with aluminum foil as the lidding material. This material pairing offers moderate barrier protection, sufficient for a wide range of pharmaceutical products that are less sensitive to environmental exposure. However, when produced using an automatic blister packing machine, PVC's natural permeability to moisture and gases means it may not be ideal for drugs that demand stringent protection, potentially limiting its use for more sensitive medications or requiring supplementary packaging solutions.

Impact on Pharmaceutical Stability

The choice between Alu-Alu and PVC blister materials plays a crucial role in maintaining pharmaceutical stability. Alu-Alu blisters, with their superior barrier properties, help extend the shelf life of sensitive drugs by shielding them from environmental degradation factors such as moisture and oxygen. In contrast, while PVC blisters are adequate for many products, drugs sensitive to moisture may require additional protective measures, such as incorporating desiccants or secondary packaging, to ensure long-term stability and efficacy.

Comparing Alu-Alu and PVC Blister Performance

Barrier Properties Analysis

Alu-Alu blisters are renowned for their exceptional barrier properties, providing almost complete protection against moisture, oxygen, and light penetration. This superior barrier capability makes them highly suitable for packaging hygroscopic and light-sensitive pharmaceutical products, ensuring product stability and efficacy throughout shelf life. In contrast, PVC blisters offer moderate barrier protection but are inherently more permeable. This permeability limits their use for drugs that require stringent environmental protection, as they may allow moisture and gases to compromise the medication's integrity over time.

Cost Considerations

When comparing costs, PVC blisters typically present a more economical option due to lower material and production expenses, especially when produced on an automatic blister packing machine. This cost-effectiveness is especially advantageous for high-volume manufacturing where budget constraints are critical. However, despite the higher initial investment, Alu-Alu blisters can offer longer shelf life and better product preservation, which may lead to reduced losses from degradation or spoilage. Therefore, in scenarios demanding enhanced protection, the benefits of Alu-Alu packaging can justify the increased upfront costs.

Environmental Impact

Environmental sustainability is a growing concern in packaging decisions. PVC blisters, being primarily plastic-based, pose considerable challenges for recycling and waste management, contributing to environmental pollution. On the other hand, Alu-Alu blisters, composed mainly of aluminum, are generally more recyclable, although they also raise some ecological concerns. Manufacturers must balance these environmental considerations with performance and cost factors, aiming to select packaging materials that align with both regulatory requirements and evolving consumer preferences for eco-friendly solutions.

Optimizing Blister Packaging Production

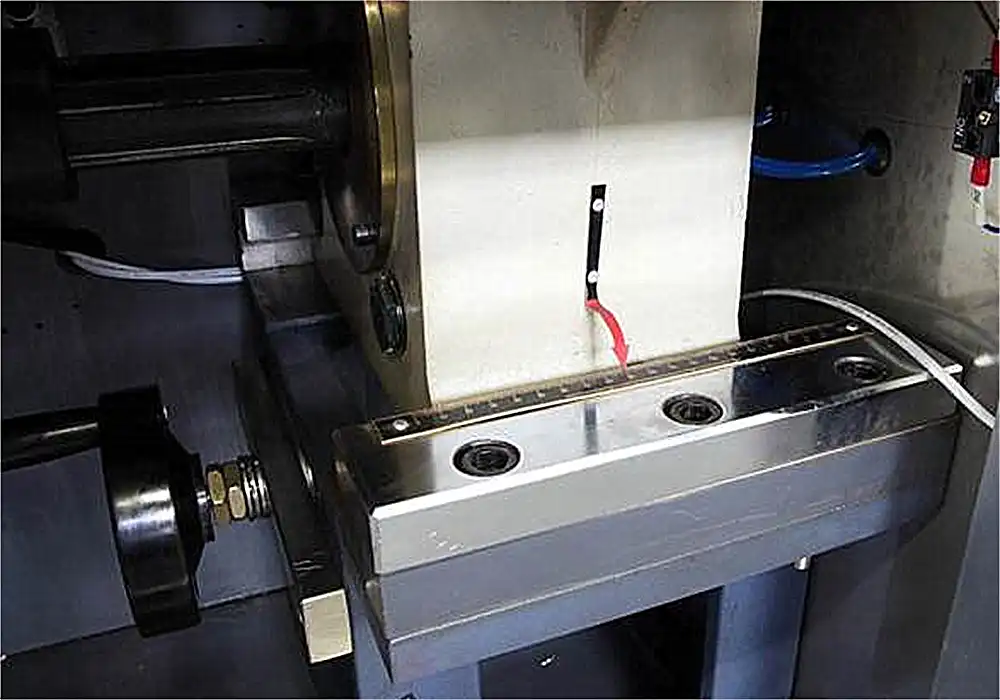

Advancements in Automatic Blister Packing Machines

The continuous evolution of automatic blister packing machines has brought significant improvements to pharmaceutical packaging processes. Modern machines are capable of handling a wide range of materials, including both Alu-Alu and PVC films, with exceptional precision and operational efficiency. This advancement not only increases production speed but also enhances packaging quality. Additionally, these machines provide versatility in designing blisters, enabling manufacturers to tailor packaging configurations to meet the unique protection and presentation needs of various pharmaceutical products.

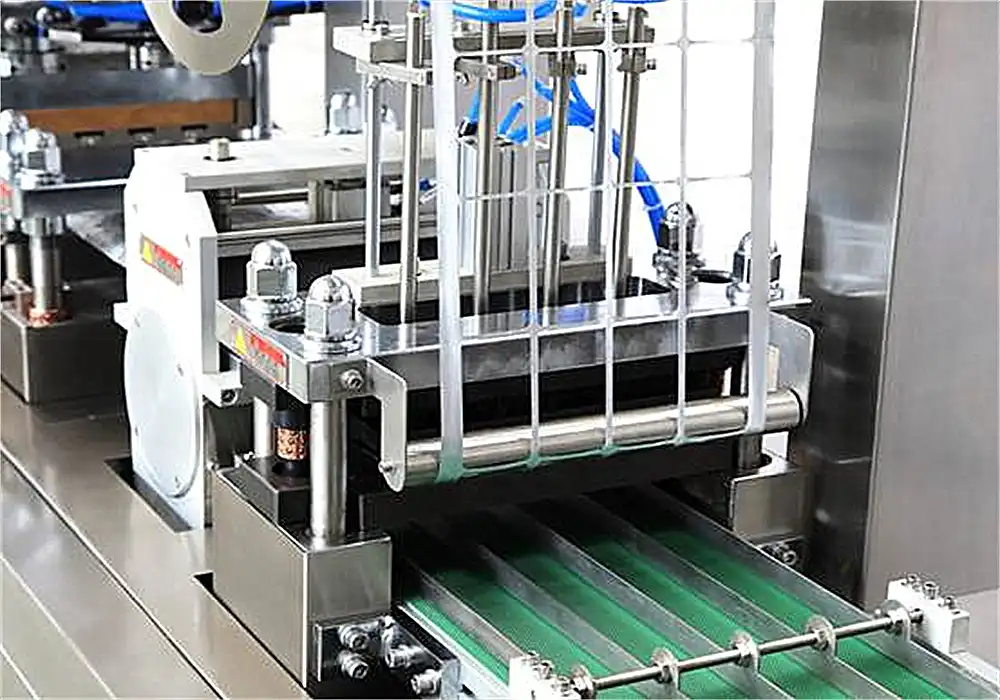

Quality Control Measures

Maintaining the integrity of blister packs is essential for ensuring drug safety and efficacy. Advanced quality control systems integrated within automatic blister packing machines allow for real-time monitoring and detection of packaging defects. This capability minimizes material waste and helps maintain consistent product safety standards. Such quality assurance features are especially critical for Alu-Alu blisters, where seal integrity must be uncompromised to protect sensitive medications from moisture, oxygen, and other environmental factors that could degrade product quality.

Customization and Flexibility

Given the pharmaceutical industry's wide-ranging product requirements, packaging solutions must be highly adaptable. Modern blister packaging equipment offers the flexibility to easily switch between Alu-Alu and PVC materials, supporting diverse product lines without lengthy downtime. This adaptability enables manufacturers to optimize their packaging approaches based on the specific characteristics of each drug and evolving market demands. The ability to customize blister designs and materials contributes to improved supply chain efficiency and helps pharmaceutical companies respond rapidly to regulatory or consumer needs.

Conclusion

The choice between Alu-Alu and PVC blisters is not one-size-fits-all. While Alu-Alu offers superior protection for sensitive medications, PVC remains a cost-effective option for less demanding applications. The decision should be based on a comprehensive assessment of drug stability requirements, cost considerations, and environmental factors. Leveraging advanced automatic blister packing machines can optimize production regardless of the chosen material, ensuring efficient, high-quality packaging solutions tailored to specific pharmaceutical needs.

Contact Us

For more information on optimizing your pharmaceutical packaging process with cutting-edge automatic blister packing machines, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our experts are ready to help you find the perfect packaging solution for your products.