Blister Packaging Machine Frequently Asked Questions

Blister packaging machines are essential equipment in various industries, particularly in pharmaceuticals, cosmetics, and consumer goods. These automatic machines efficiently seal products in pre-formed plastic cavities, providing protection and visual appeal. As a leading manufacturer of packaging solutions, we often receive inquiries about blister packaging machines. This comprehensive FAQ guide addresses common questions about automatic blister packing machines and pharma blister packing machines, helping you make informed decisions for your packaging needs. Whether you're considering investing in a new machine or upgrading your existing equipment, this article will provide valuable insights into blister packaging technology, operation, maintenance, and industry applications.

Understanding Blister Packaging Technology

What is blister packaging?

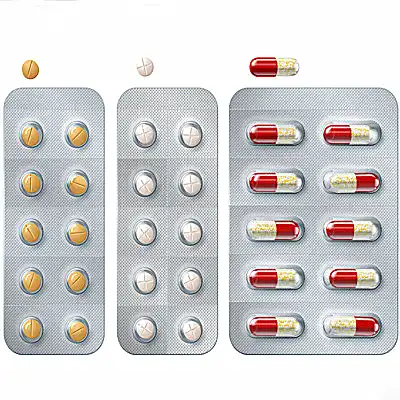

Blister packaging is a popular method of packaging products in pre-formed plastic cavities, often with a backing of paperboard or aluminum foil. This type of packaging offers excellent product protection, tamper-evidence, and visual appeal. Blister packs are commonly used for pharmaceuticals, electronics, toys, and various consumer goods.

How does an automatic blister packing machine work?

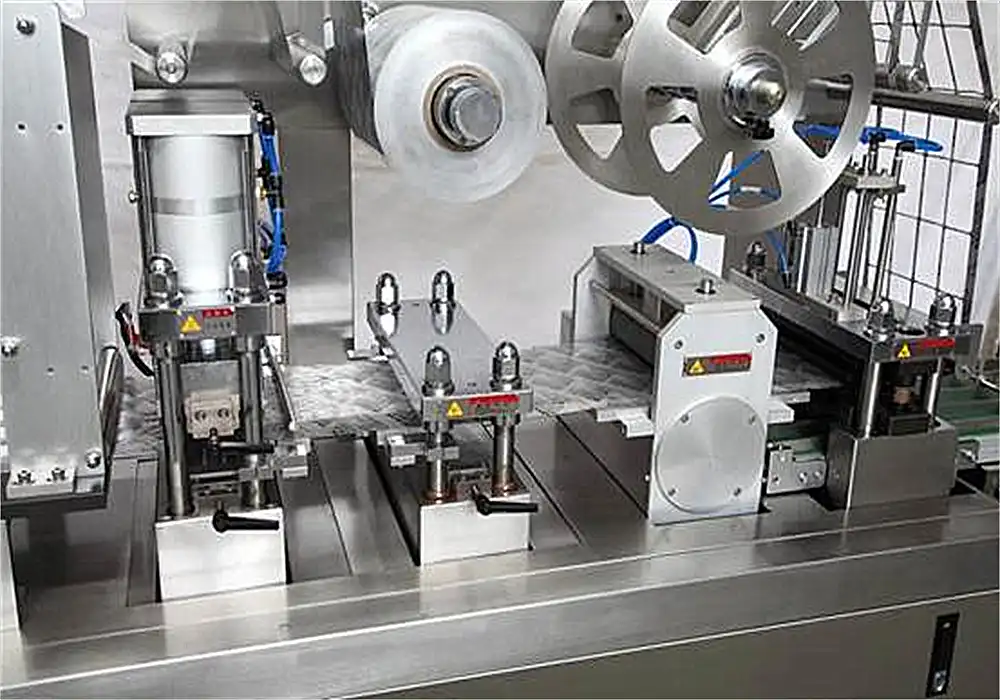

An automatic blister packing machine operates through a series of steps to create sealed blister packages. First, it forms the plastic cavities using heat and pressure. Then, it places the product into these cavities, either manually or through automated feeding systems. Finally, the machine seals the filled blisters with a backing material, typically using heat sealing or cold sealing methods. Advanced machines can perform additional tasks like printing, coding, and quality control inspections.

What are the key components of a pharma blister packing machine?

A pharma blister packing machine consists of several crucial components:

- Forming station: Creates the plastic cavities

- Feeding system: Places products into the cavities

- Sealing station: Applies the backing material

- Cutting station: Separates individual blister packs

- Control panel: Manages machine operations

- Heating and cooling systems: Regulate temperature for forming and sealing

- Safety features: Ensure operator protection

- Quality control systems: Monitor package integrity and product presence

Choosing the Right Blister Packaging Machine

What factors should I consider when selecting a blister packaging machine?

When choosing a blister packaging machine, consider the following factors:

- Production volume: Determine the required output capacity

- Product specifications: Consider size, shape, and material compatibility

- Packaging material: Ensure compatibility with your chosen blister and backing materials

- Automation level: Decide between semi-automatic and fully automatic options

- Flexibility: Assess the machine's ability to handle different product sizes and shapes

- Compliance: Ensure the machine meets industry standards and regulations

- Integration: Consider how the machine will fit into your existing production line

- Budget: Balance initial investment with long-term operational costs

- After-sales support: Evaluate the manufacturer's service and spare parts availability

What are the differences between semi-automatic and fully automatic blister packing machines?

Semi automatic blister packing machines require some manual intervention, typically in product loading or package removal. They are suitable for smaller production runs or businesses with limited space. Fully automatic machines handle the entire packaging process without manual intervention, offering higher production speeds and consistency. They are ideal for large-scale manufacturing and pharmaceutical applications where strict quality control is essential.

How do I determine the right capacity for my blister packaging needs?

To determine the appropriate capacity for your blister packaging machine:

- Calculate your current production requirements

- Factor in projected growth and seasonal fluctuations

- Consider your available floor space and labor resources

- Evaluate your budget constraints

- Consult with packaging equipment experts to find the best balance between capacity and efficiency

Maintenance and Troubleshooting

What routine maintenance does a blister packaging machine require?

Regular maintenance is crucial for optimal performance and longevity of your blister packaging machine. Key maintenance tasks include:

- Daily cleaning of product contact surfaces

- Lubrication of moving parts as per the manufacturer's schedule

- Inspection and replacement of worn sealing tools

- Calibration of temperature and pressure settings

- Checking and tightening of electrical connections

- Monitoring and replacing air filters in pneumatic systems

- Updating software and firmware as recommended by the manufacturer

How can I troubleshoot common issues with my automatic blister packing machine?

When facing issues with your pharma blister packing machine, follow these troubleshooting steps:

- Check for proper material loading and alignment

- Verify temperature and pressure settings

- Inspect sealing tools for wear or damage

- Ensure proper product feeding and placement

- Check for any obstructions in the machine's path

- Review error messages on the control panel

Consult the machine's manual for specific troubleshooting guides If problems persist, contact the manufacturer's technical support team for assistance.

What are the best practices for maximizing the lifespan of a pharma blister packing machine?

To maximize the lifespan of your pharma blister packing machine:

- Follow the manufacturer's recommended maintenance schedule

- Train operators thoroughly on proper machine operation

- Use only compatible materials and consumables

- Keep the machine clean and free from product residue

- Perform regular quality checks and adjustments

- Upgrade software and components as recommended

- Store the machine in a controlled environment when not in use

- Address minor issues promptly to prevent major breakdowns

Conclusion

Blister packaging machines play a crucial role in modern manufacturing and packaging processes. By understanding the technology, selecting the right equipment, and implementing proper maintenance practices, you can maximize the efficiency and longevity of your blister packaging operations. Whether you're in the pharmaceutical industry or producing consumer goods, investing in a high-quality automatic blister packing machine or pharma blister packing machine can significantly enhance your packaging capabilities and product presentation.

Contact Us

For more information about our range of blister packaging solutions and how they can benefit your business, please contact us at [email protected]. Our team of experts is ready to assist you in finding the perfect packaging solution for your specific needs.

References

Johnson, M. (2022). Advances in Pharmaceutical Blister Packaging Technology. Journal of Packaging Science and Technology, 15(3), 45-62.

Smith, A. & Brown, L. (2021). Optimization of Blister Pack Design for Consumer Products. International Journal of Packaging Research, 8(2), 112-128.

Garcia, R. (2023). Sustainable Materials in Blister Packaging: Trends and Innovations. Green Packaging Quarterly, 7(1), 18-33.

Lee, S. et al. (2022). Quality Control Mechanisms in Automated Blister Packaging Systems. Pharmaceutical Engineering Review, 12(4), 76-91.

Wilson, T. (2021). Energy Efficiency in Modern Blister Packaging Machines. Industrial Energy Management, 9(3), 55-70.

Zhang, Y. & Patel, K. (2023). Integration of IoT in Pharmaceutical Blister Packaging: A Case Study. Smart Manufacturing Journal, 6(2), 102-117.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?