The Evolution of Blister Packaging Technology

From Manual to Automated: A Packaging Revolution

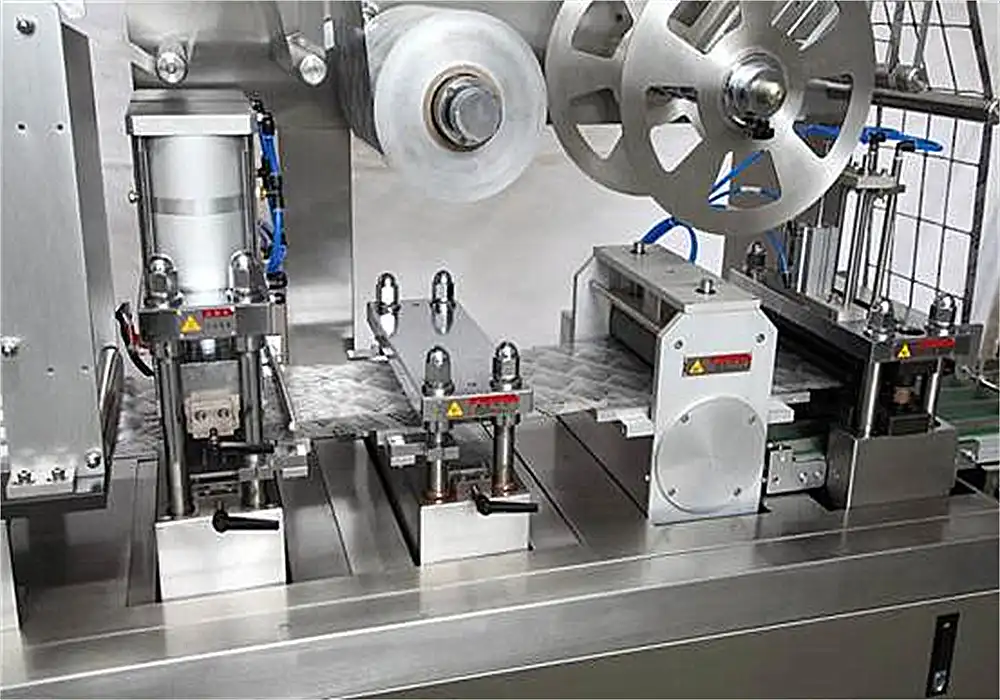

The journey of blister packaging machines from their humble beginnings to the sophisticated equipment we see today is nothing short of remarkable. Initially, blister packaging was a labor-intensive process, requiring significant manual intervention. However, as technological advancements accelerated, so did the capabilities of these machines. The introduction of automation marked a watershed moment, drastically improving efficiency and consistency in packaging operations.

Key Innovations in Blister Packaging Machinery

Over the years, blister packaging machines have undergone numerous innovations. The integration of servo motors has allowed for more precise control and higher speeds. Advanced sealing technologies ensure hermetic closure, critical for pharmaceutical products. Moreover, the incorporation of vision systems for quality control has significantly reduced error rates, ensuring each package meets stringent standards.

Industry-Specific Adaptations

As the demand for specialized packaging grew, so did the versatility of blister packaging machines. The pharmaceutical industry, in particular, saw the development of pharma blister packing machines designed to meet strict regulatory requirements. These machines often feature cleanroom compatibility and materials suitable for medical-grade packaging. Similarly, the food and consumer goods sectors have benefited from customized solutions that cater to their unique packaging needs.

Advantages of Modern Blister Packaging Machines

Enhanced Productivity and Efficiency

Modern blister packaging machines significantly boost production efficiency by operating at high speeds, often capable of processing thousands of units per hour. This rapid output allows pharmaceutical and consumer goods manufacturers to meet high demand without compromising quality. In addition to increased throughput, automation reduces the need for manual labor, which lowers operational costs and minimizes human error. These benefits make automatic blister packing machines a cost-effective and reliable choice for businesses aiming to optimize their packaging lines.

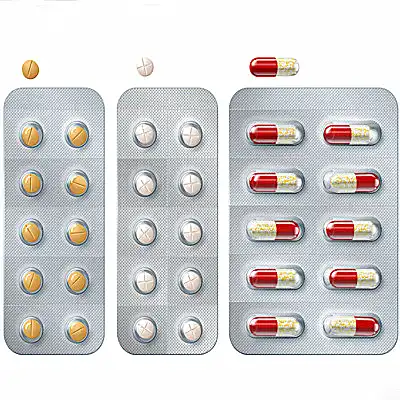

Superior Product Protection and Presentation

Blister packaging provided by automatic blister packing machines offers robust protection against environmental factors such as moisture, light, and contamination, ensuring product stability and safety - especially important for sensitive pharmaceutical products. The transparent plastic cavities allow consumers and quality inspectors to visually verify the contents, which helps build trust and ensures quality control. This clear presentation not only safeguards product integrity but also enhances the overall consumer experience by making the product easily identifiable and appealing on retail shelves.

Flexibility and Customization Options

Designed to meet diverse manufacturing needs, modern blister packaging machines offer exceptional flexibility. They accommodate various product sizes and shapes, ranging from small tablets to larger items, supporting a broad array of packaging formats. Many machines feature quick changeover systems, enabling fast transitions between different product lines with minimal downtime. This adaptability allows manufacturers to efficiently handle multiple product types, supporting evolving market demands and helping companies maintain a competitive edge with versatile and customizable packaging solutions.

Selecting the Right Blister Packaging Machine for Your Needs

Assessing Production Requirements

Choosing the appropriate blister packaging machine begins with a thorough evaluation of your specific production demands. Important considerations include the desired output rate, the nature and size of the products, and the types of packaging materials you intend to use. High-volume manufacturers may benefit from fully automatic blister packing machines that offer speed and efficiency, while smaller-scale operations might find semi-automatic machines more cost-effective and easier to manage, balancing investment with production needs.

Compliance and Quality Considerations

In regulated sectors like pharmaceuticals, compliance with industry standards is critical when selecting a blister packaging machine. Pharma blister packing machines often incorporate specialized features such as cleanroom compatibility, automated validation protocols, and comprehensive documentation to support regulatory audits. Choosing equipment that meets or exceeds these quality and compliance requirements ensures product safety, maintains integrity throughout packaging, and helps avoid costly regulatory setbacks or product recalls.

Future-Proofing Your Investment

Given the rapid pace of technological advancements, it is important to invest in blister packaging machines that offer scalability and adaptability. Modular designs facilitate the integration of new functionalities or upgrades, extending the machine’s useful life. Additionally, partnering with manufacturers known for innovation and reliable customer support guarantees access to ongoing software updates and technical assistance, protecting your investment and enabling your packaging line to evolve alongside industry trends and market demands.

Conclusion

Modern blister packaging machines represent a significant leap forward in packaging technology, offering unparalleled efficiency, precision, and versatility. From automatic blister packing machines to specialized pharma blister packing machines, these devices have revolutionized how products are packaged and presented to consumers. By enhancing productivity, ensuring product protection, and providing customizable solutions, blister packaging machines have become an indispensable tool for businesses across various industries. As technology continues to advance, we can expect even more innovative features and capabilities in the future of blister packaging machinery.

Contact Us

Ready to elevate your packaging game? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] to explore our range of cutting-edge blister packaging solutions tailored to your specific needs.