Understanding Blister Packaging Machines

The Mechanics of Blister Packaging

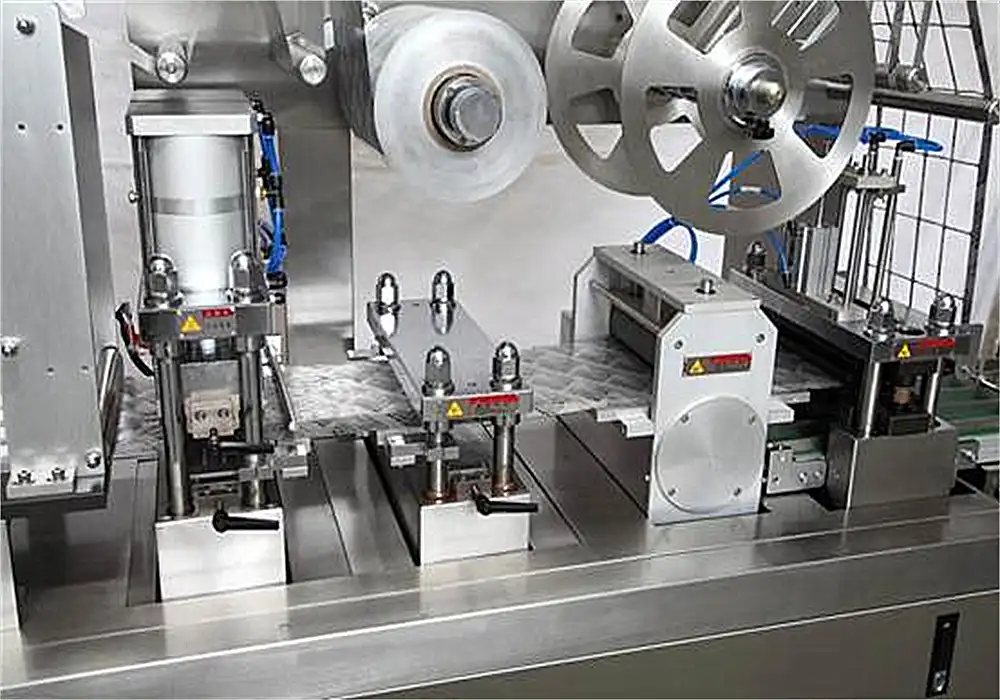

Blister packaging machines are sophisticated pieces of equipment designed to create individual cavities or "blisters" that house products securely. These machines typically use thermoforming or cold forming processes to shape plastic or aluminum materials into precise compartments. The product is then placed into these cavities and sealed with a backing material, which is often foil or plastic film.

The process begins with the formation of the blister cavity, followed by product insertion, sealing, and finally, cutting and perforating to create individual units. This method ensures each product is hermetically sealed, protecting it from external factors such as moisture, light, and contaminants.

Advantages of Blister Packaging

Blister packaging, produced using a blister packaging machine, offers numerous benefits that make it a preferred choice in various industries. Foremost among these is the superior protection it provides to the packaged product. The rigid structure of the blister prevents crushing or damage during transport and handling. Additionally, the transparency of many blister materials allows for visual inspection of the product without compromising the package integrity.

Another significant advantage is the tamper-evidence feature inherent in blister packaging. Any attempt to access the product leaves visible signs, enhancing consumer safety and product authenticity. This aspect is particularly crucial in the pharmaceutical industry, where drug safety is paramount.

Applications and Industries

While blister packaging machines are most commonly associated with pharmaceuticals, their applications extend far beyond. In the healthcare sector, they're used for packaging tablets, capsules, medical devices, and even surgical instruments. The consumer goods industry utilizes blister packaging for items like batteries, electronics, and personal care products.

The food industry also benefits from blister packaging, particularly for portion-controlled items and convenience foods. The ability to create custom-shaped cavities makes blister packaging adaptable to a wide range of product sizes and shapes, offering versatility across various sectors.

Exploring Strip Packing Machines

The Strip Packing Process

Strip packing machines operate on a different principle compared to blister packaging machines. These devices create a continuous strip of sealed packets, each containing the product. The process involves feeding two layers of packaging material – typically foil or plastic film – into the machine. The product is then dosed between these layers, which are subsequently sealed together to form individual pockets.

The sealed strip is then cut into individual units or left as a continuous strip, depending on the application. This method is particularly efficient for packaging small, uniform products like tablets, capsules, or powders in high volumes.

Benefits of Strip Packaging

One of the primary advantages of strip packing machines is their high production speed. These machines can package thousands of units per minute, making them ideal for large-scale production. The continuous nature of the process also results in less material waste compared to some other packaging methods.

Strip packaging is also highly cost-effective, especially for high-volume production. The packaging materials used are generally less expensive than those required for blister packaging. Additionally, strip packages are compact and lightweight, reducing transportation and storage costs.

Ideal Products and Industries

Strip packing machines find their niche primarily in the pharmaceutical industry, where they're used extensively for packaging tablets, capsules, and powders. They're particularly well-suited for products that don't require the rigid protection offered by blister packaging.

Beyond pharmaceuticals, strip packaging is utilized in the food industry for single-serve condiments, powdered drinks, and dietary supplements. The method is also gaining popularity in the nutraceutical sector for packaging vitamins and herbal products.

Comparing Blister and Strip Packaging Technologies

Production Efficiency and Speed

When it comes to production efficiency, strip packing machines generally have the edge. These machines can operate at extremely high speeds, often producing thousands of packages per minute. This high-speed capability makes them ideal for large-scale production runs where time is of the essence.

Blister packaging machines, while not as fast as strip packers, offer more flexibility in terms of product size and shape. They can handle a wider variety of products but typically operate at lower speeds. The trade-off is often between speed and versatility, with blister machines offering more options for customization.

Product Protection and Shelf Life

In terms of product protection, blister packaging machines often have the advantage. The rigid structure of blister packs provides excellent protection against physical damage during transport and handling. Additionally, the ability to use high-barrier materials in blister packaging can significantly extend product shelf life by protecting against moisture, oxygen, and light.

Strip packaging, while offering good protection, may not be as robust as blister packaging for certain products. However, it can still provide adequate protection for many items, especially when using appropriate barrier materials. The choice often depends on the specific requirements of the product being packaged.

Cost Considerations and ROI

Cost is a crucial factor in choosing between blister and strip packaging machines. Generally, strip packing machines have lower initial costs and lower operating costs due to simpler mechanics and less expensive packaging materials. This can result in a quicker return on investment, especially for high-volume production.

Blister packaging machines, while potentially more expensive upfront, offer greater versatility and may provide better long-term value for companies with diverse product lines. The higher cost of blister packaging materials is often offset by the enhanced product protection and presentation, which can justify premium pricing for the final product.

Conclusion

Choosing between a blister packaging machine and a strip packing machine depends on various factors including product characteristics, production volume, budget, and market requirements. Blister packaging excels in product protection and presentation, making it ideal for pharmaceuticals and high-value items. Strip packaging offers high-speed production and cost-effectiveness, suitable for large-scale pharmaceutical and food industry applications. Both technologies continue to evolve, with advancements in materials and machinery enhancing their capabilities. Ultimately, the decision should align with your specific packaging needs and long-term business strategy.

Contact Us

For more information on choosing the right packaging solution for your needs, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our experts are ready to help you find the perfect packaging solution for your products.