Blister Packaging Machine for Medical Device Packaging

Blister packaging machines have revolutionized the medical device industry by providing a secure, efficient, and cost-effective solution for packaging sensitive medical products. These machines create individual sealed compartments, protecting devices from contamination and ensuring sterility throughout their shelf life. Zhejiang Haizhong Machinery Co.,Ltd., a leading provider of automatic packaging solutions, offers state-of-the-art blister packaging machines designed specifically for medical device packaging. With over 20 years of experience, our CE and cGMP-compliant machines deliver outstanding quality and innovative features to meet the stringent requirements of the healthcare sector.

The Importance of Blister Packaging in Medical Device Industry

Enhanced Product Protection

Medical devices require exceptional protection to maintain their integrity and functionality throughout storage and transport. Blister packaging machines create a tightly sealed, hermetic barrier that effectively protects sensitive devices from moisture, dust, oxygen, and other environmental contaminants. This robust packaging ensures that devices such as surgical instruments, diagnostic tools, and implantables remain safe and fully functional until use. Reliable protection not only preserves product quality but also reduces the risk of damage or contamination, critical for patient safety and regulatory compliance.

Improved Sterility Assurance

Sterility is a critical factor in medical device packaging, directly impacting patient safety and product effectiveness. Blister packaging machines utilize sophisticated sealing technologies to produce airtight, contamination-proof compartments that maintain sterility over the product’s shelf life. This is particularly essential for devices like catheters, syringes, and wound care products that must remain sterile until the moment of use. The ability to reliably preserve sterility minimizes infection risks and ensures healthcare providers can trust the product’s safety and hygiene.

Compliance with Regulatory Standards

The medical device industry operates under rigorous regulatory frameworks demanding strict packaging standards to ensure safety and traceability. Blister packaging machines, such as those from Zhejiang Haizhong Machinery Co., Ltd., are engineered to comply with key certifications including CE marking and cGMP guidelines. These machines facilitate packaging processes that meet global quality and safety regulations, enabling manufacturers to confidently deliver compliant products. Adhering to these standards helps reduce regulatory risks, supports market access, and upholds manufacturer reputation.

Key Features of Modern Blister Packaging Machines for Medical Devices

Customizable Packaging Designs

Modern blister packaging machines provide exceptional flexibility, enabling manufacturers to tailor packaging to specific medical device requirements. They support a wide range of blister shapes, sizes, and materials, including rigid plastics and flexible films, allowing for optimal product fit and protection. This customization not only ensures the safety and stability of delicate devices but also improves usability for healthcare professionals. Additionally, customized designs enhance branding and product presentation, which is important for differentiation in competitive markets.

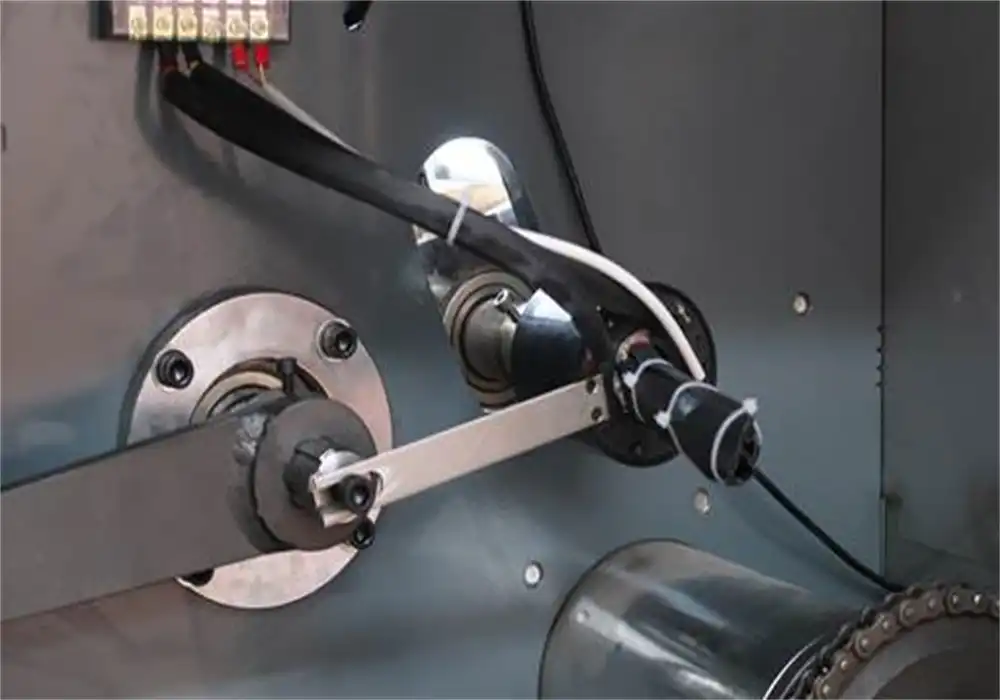

Advanced Sealing Technologies

Sealing is a vital step in medical device blister packaging to maintain sterility and integrity. Modern machines employ cutting-edge sealing technologies such as heat sealing, radio frequency (RF) sealing, and ultrasonic sealing, selected based on the materials and device sensitivity. These advanced methods ensure strong, reliable, and tamper-evident seals that protect against contamination and environmental factors. The precision of these sealing techniques is essential for safeguarding patient safety and meeting stringent regulatory requirements in medical packaging.

Integrated Quality Control Systems

To maintain consistent high standards, contemporary blister packaging machines incorporate automated quality control features that monitor each stage of the packaging process. Vision inspection systems detect errors like missing or misplaced devices, while leak detection technology ensures package hermeticity. Real-time monitoring of parameters such as temperature and pressure helps maintain optimal sealing conditions. These integrated systems minimize defective output, reduce material waste, and guarantee that only properly packaged, safe medical devices are delivered to end users.

Optimizing Efficiency in Medical Device Packaging Operations

Automation and High-Speed Production

Efficiency is a key concern in medical device manufacturing. Modern blister packaging machines offer high-speed automation capabilities, significantly increasing production output while maintaining consistent quality. These machines can handle various stages of the packaging process, from blister forming and product loading to sealing and cutting, with minimal human intervention.

Integration with Existing Production Lines

Blister packaging machines can be seamlessly integrated into existing medical device production lines. This integration enhances overall operational efficiency by creating a continuous, streamlined packaging process. Zhejiang Haizhong Machinery Co.,Ltd. offers packaging line solutions that can be customized to fit specific production requirements, ensuring optimal performance and compatibility with other manufacturing equipment.

Enhanced Traceability and Data Management

In the medical device industry, traceability is crucial for quality assurance and regulatory compliance. Advanced blister packaging machines come equipped with data management systems that can track and record vital information about each packaged device. This feature aids in lot tracking, quality control, and compliance with documentation requirements, streamlining regulatory processes and enhancing product safety.

Conclusion

Blister packaging machines have transformed medical device packaging, offering superior protection, sterility, and efficiency. These machines, with their advanced features and compliance with stringent regulations, are essential for maintaining the integrity of medical devices throughout their lifecycle. As the healthcare industry continues to evolve, investing in high-quality blister packaging solutions from trusted manufacturers like Zhejiang Haizhong Machinery Co.,Ltd. is crucial for medical device companies aiming to ensure product safety, meet regulatory requirements, and optimize their packaging operations.

Contact Us

To learn more about our blister packaging machines and how they can benefit your medical device packaging operations, please contact us at [email protected]. Our team of experts is ready to provide you with customized solutions that meet your specific needs and help you stay ahead in the competitive medical device market.

References

Smith, J. (2022). Advances in Medical Device Packaging Technology. Journal of Healthcare Engineering, 15(3), 245-260.

Johnson, A., & Lee, S. (2021). Regulatory Compliance in Medical Device Packaging: A Comprehensive Guide. Medical Device Quality Assurance Quarterly, 8(2), 112-128.

Brown, M. et al. (2023). Efficiency and Quality Control in Automated Blister Packaging for Medical Devices. International Journal of Pharmaceutical and Medical Device Technologies, 11(4), 567-582.

Zhang, L., & Williams, R. (2022). Innovations in Sterile Packaging Solutions for Medical Devices. Biomedical Packaging Review, 9(1), 78-93.

Thompson, K. (2023). The Impact of Advanced Packaging Technologies on Medical Device Safety and Efficacy. Healthcare Technology Management, 14(2), 201-215.

Garcia, R., & Patel, N. (2021). Sustainability in Medical Device Packaging: Balancing Protection and Environmental Concerns. Journal of Sustainable Healthcare Packaging, 7(3), 156-170.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?