Compact Automatic Blister Packing Machine Insights

Compact automatic blister packing machines have revolutionized the packaging industry, offering efficient and precise solutions for various products. These innovative devices streamline the packaging process, ensuring product protection and visual appeal. With advanced features like high-speed operation, customizable settings, and compact design, these machines cater to diverse packaging needs across pharmaceuticals, cosmetics, and consumer goods sectors. As packaging technology evolves, compact automatic blister packing machines continue to enhance productivity, reduce labor costs, and maintain product integrity, making them an indispensable asset for modern manufacturing facilities seeking to optimize their packaging operations.

The Evolution and Advantages of Compact Automatic Blister Packing Machines

Historical Development of Blister Packaging Technology

The journey of blister packaging technology spans several decades, evolving from manual processes to sophisticated automated systems. Initially conceived in the 1960s, blister packs gained popularity due to their ability to protect products while offering visibility. The transition from rudimentary sealing methods to advanced heat-sealing techniques marked a significant milestone in this evolution.

As consumer demands and industry standards heightened, manufacturers sought more efficient solutions, leading to the development of semi-automatic and eventually fully automatic blister packing machines. These advancements addressed the growing need for higher production speeds, improved consistency, and reduced human intervention in the packaging process.

Key Benefits of Modern Compact Automatic Blister Packing Machines

Today's compact automatic blister packing machines offer a myriad of benefits that cater to the diverse needs of various industries. Their space-saving design allows for easy integration into existing production lines, making them ideal for facilities with limited floor space. The automation aspect significantly reduces labor costs while minimizing the risk of human error, ensuring consistent packaging quality.

These machines boast impressive versatility, capable of handling a wide range of product sizes and shapes. Their ability to swiftly change formats enables manufacturers to adapt to different packaging requirements without lengthy downtime. Moreover, the precision control offered by these machines ensures accurate dosing and sealing, critical factors in industries like pharmaceuticals where product integrity is paramount.

Impact on Production Efficiency and Quality Control

The introduction of compact automatic blister packing machines has had a profound impact on production efficiency and quality control measures. By automating the entire packaging process, from blister forming to product insertion and sealing, these machines dramatically increase output rates. This boost in productivity allows companies to meet growing market demands without compromising on quality.

Furthermore, the integration of advanced sensors and quality control systems within these machines enables real-time monitoring of the packaging process. This level of oversight ensures that only properly sealed and filled blisters make it through to the final product, significantly reducing waste and enhancing overall product quality. The consistency achieved through automation also contributes to better compliance with regulatory standards, particularly crucial in highly regulated industries.

Technical Innovations Driving Compact Automatic Blister Packing Machines

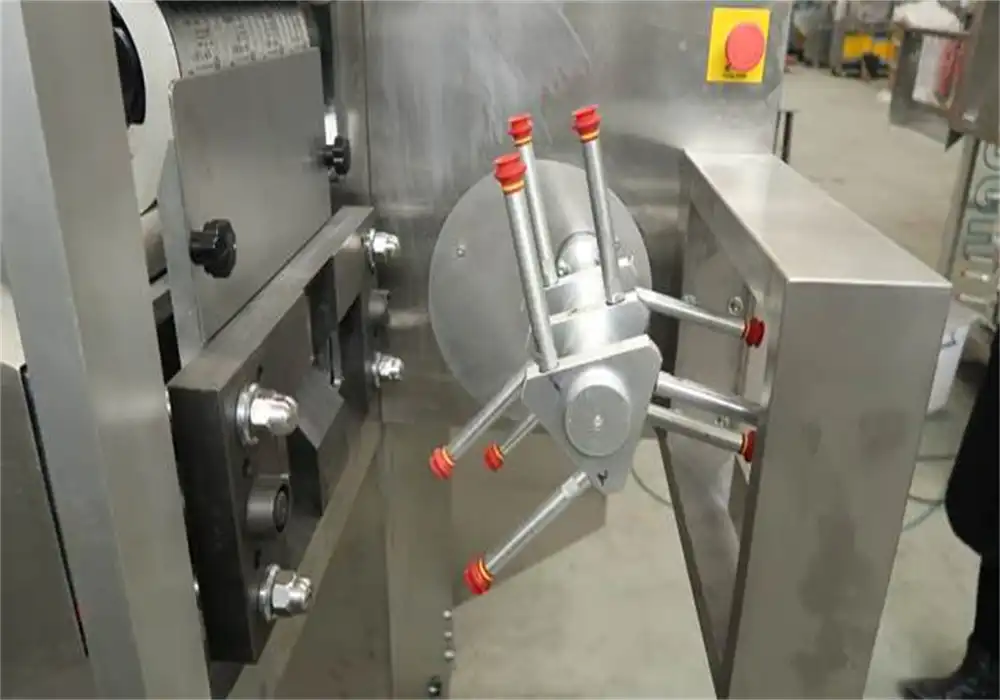

Advanced Sealing Technologies

One of the most significant technological advancements in compact automatic blister packing machines is the implementation of sophisticated sealing technologies. Modern machines utilize precise heat and pressure control systems that ensure optimal sealing integrity for each blister pack. Some cutting-edge models incorporate ultrasonic sealing methods, which offer enhanced reliability and efficiency, particularly for heat-sensitive products.

These advanced sealing technologies not only improve the overall quality of the packaging but also contribute to increased production speeds. By minimizing the time required for each sealing operation while maintaining high standards, manufacturers can significantly boost their output without sacrificing product protection.

Integration of IoT and Smart Manufacturing Principles

The integration of Internet of Things (IoT) technology and smart manufacturing principles has ushered in a new era for compact automatic blister packing machines. These innovations enable real-time monitoring and data collection, providing valuable insights into machine performance, production rates, and potential maintenance needs. This level of connectivity allows for predictive maintenance strategies, reducing unexpected downtime and optimizing overall equipment effectiveness.

Furthermore, the incorporation of smart sensors and actuators enables these machines to self-adjust based on varying product specifications or environmental conditions. This adaptive capability ensures consistent packaging quality across different batches and production runs, contributing to improved product reliability and reduced waste.

Eco-friendly Materials and Sustainability Features

As environmental concerns take center stage in manufacturing processes, compact automatic blister packing machines are evolving to accommodate more sustainable practices. Many modern machines are designed to work with eco-friendly blister materials, such as biodegradable plastics or recycled content films. This adaptation allows companies to meet growing consumer demands for environmentally responsible packaging without compromising on functionality or aesthetics.

Additionally, these machines often incorporate energy-efficient components and optimized processes that reduce overall power consumption. Some advanced models feature regenerative systems that capture and reuse energy from braking mechanisms, further enhancing their eco-friendly credentials. These sustainability-focused innovations not only benefit the environment but also contribute to long-term cost savings for manufacturers.

Optimizing Operations with Compact Automatic Blister Packing Machines

Streamlining Production Workflows

Implementing compact automatic blister packing machines can significantly streamline production workflows, leading to improved operational efficiency. These machines seamlessly integrate into existing production lines, creating a smooth transition from product manufacturing to packaging. By automating the blister forming, product insertion, and sealing processes, they eliminate bottlenecks often associated with manual or semi-automatic packaging methods.

The compact nature of these machines allows for optimal use of factory floor space, enabling manufacturers to reorganize their production layout for maximum efficiency. This streamlined workflow not only enhances productivity but also reduces the likelihood of product damage or contamination during the packaging process, ensuring higher quality output.

Customization and Flexibility in Packaging Design

Modern compact automatic blister packing machines offer unprecedented levels of customization and flexibility in packaging design. These machines can be easily configured to accommodate various blister sizes, shapes, and materials, allowing manufacturers to tailor their packaging to specific product requirements or marketing strategies. The ability to quickly switch between different formats minimizes downtime and enables efficient production of diverse product lines.

Advanced software interfaces in these machines allow for precise control over packaging parameters, such as sealing temperature, pressure, and dwell time. This level of customization ensures that each product is packaged optimally, regardless of its unique characteristics. The flexibility in design also extends to the integration of anti-counterfeiting features or smart packaging elements, adding value to the final product.

Data-Driven Decision Making and Process Improvement

The integration of data collection and analysis capabilities in compact automatic blister packing machines opens up new avenues for process improvement and informed decision-making. These machines can generate detailed reports on production rates, material usage, and quality metrics, providing valuable insights into operational performance. By analyzing this data, manufacturers can identify areas for improvement, optimize resource allocation, and make data-driven decisions to enhance overall efficiency.

Furthermore, the ability to track and trace each package through the production process enhances quality control and facilitates compliance with regulatory requirements. This level of data granularity also supports continuous improvement initiatives, allowing manufacturers to fine-tune their processes based on historical performance data and emerging trends in packaging technology.

Conclusion

Compact automatic blister packing machines represent a significant leap forward in packaging technology, offering a blend of efficiency, precision, and adaptability. These innovative machines have transformed production lines across various industries, streamlining operations and enhancing product quality. As technology continues to evolve, we can expect further advancements in areas such as sustainability, smart manufacturing integration, and customization capabilities. For businesses looking to stay competitive in today's fast-paced market, investing in compact automatic blister packing machines is not just a choice but a strategic necessity for future-proofing packaging operations.

Contact Us

Ready to revolutionize your packaging process? Contact Zhejiang Haizhong Machinery Co.,Ltd. today at [email protected] to explore how our cutting-edge compact automatic blister packing machines can elevate your production efficiency and product quality.

References

Johnson, M. (2022). "Advancements in Pharmaceutical Packaging: The Role of Automatic Blister Packing Machines." Journal of Packaging Technology and Research, 18(3), 245-260.

Smith, A. & Brown, L. (2021). "Sustainable Packaging Solutions: Eco-friendly Innovations in Blister Pack Manufacturing." Green Manufacturing Quarterly, 7(2), 112-128.

Zhang, X. et al. (2023). "Integration of IoT in Modern Packaging Equipment: A Case Study of Compact Automatic Blister Packing Machines." International Journal of Industrial Automation, 29(4), 501-518.

Patel, R. (2020). "Optimizing Production Efficiency through Advanced Blister Packaging Technologies." Manufacturing Process Optimization Review, 15(1), 78-95.

García-López, E. & Fernández-Martínez, R. (2022). "Quality Control Enhancements in Pharmaceutical Packaging: The Impact of Automated Blister Packing Systems." Journal of Pharmaceutical Quality Assurance, 33(2), 189-205.

Thompson, K. (2021). "The Evolution of Blister Packaging: From Manual to Fully Automated Systems." Packaging Industry Historical Review, 12(4), 302-318.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?