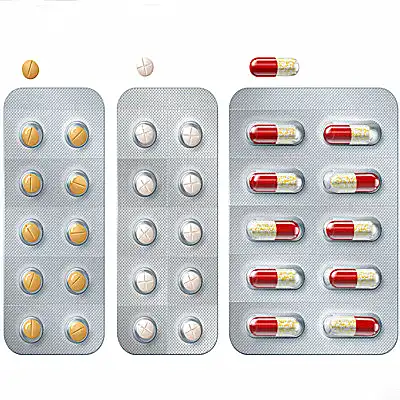

How Medical Automation Impacts Blister Packing?

Medical automation has revolutionized the pharmaceutical packaging industry, particularly in the realm of blister packing. The integration of automatic blister packing machines has significantly enhanced efficiency, precision, and quality control in medication packaging. This technological advancement has led to increased production speeds, reduced human error, and improved product safety. By automating the blister packing process, pharmaceutical companies can meet stringent regulatory requirements while optimizing their manufacturing operations. The impact of medical automation on blister packing extends beyond mere productivity gains, influencing everything from cost-effectiveness to patient safety and compliance.

The Evolution of Blister Packing in the Pharmaceutical Industry

Traditional Blister Packing Methods

Blister packing has been a fundamental technique in pharmaceutical packaging, providing product protection, dosage control, and consumer convenience. Initially, the process was predominantly manual, requiring skilled workers to place medications into pre-formed plastic cavities and seal them with foil backing. Although effective for small batches, this manual method was labor-intensive, time-consuming, and susceptible to human error, which limited overall production capacity and consistency.

Introduction of Semi-Automated Systems

With increasing market demand, semi-automated blister packing systems were developed to improve efficiency. These systems combined manual product loading with mechanized sealing and cutting operations. While this hybrid approach increased production speed and improved consistency compared to fully manual methods, it still relied heavily on operator involvement. Semi-automation represented a transitional phase that emphasized the pharmaceutical industry's need for faster, more reliable packaging processes.

The Rise of Fully Automated Blister Packing Machines

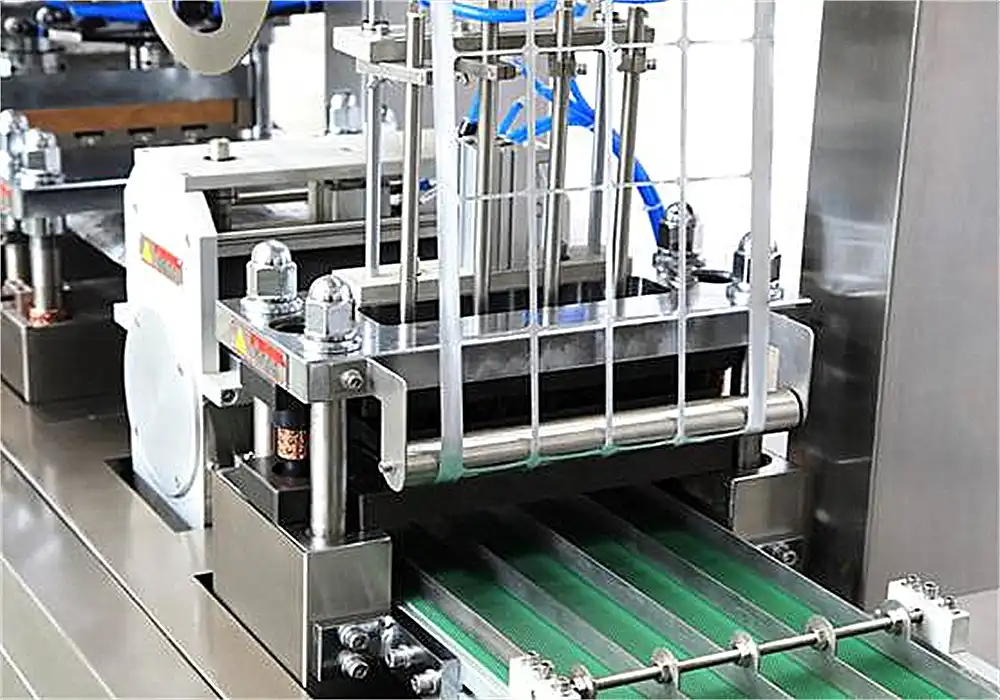

The introduction of fully automated blister packing machines revolutionized pharmaceutical packaging by streamlining the entire process. These advanced systems manage blister forming, product insertion, sealing, and cutting without manual intervention. Modern automatic blister packing machines incorporate cutting-edge technologies such as robotics, vision inspection, and precision sensors to maintain high accuracy and quality standards while operating at rapid speeds, meeting the demands of large-scale pharmaceutical production.

Key Benefits of Automated Blister Packing in Medical Manufacturing

Enhanced Productivity and Efficiency

Automated blister packing machines have transformed pharmaceutical manufacturing by significantly boosting production capacity. These machines operate continuously with minimal downtime, capable of producing thousands of blister packs per hour. Their speed and reliability far exceed manual or semi-automated methods, enabling manufacturers to meet escalating market demands. This increased throughput not only shortens lead times but also supports scalability, making automated blister packing a critical asset for high-volume medical manufacturing environments.

Improved Quality Control and Compliance

Ensuring product quality and regulatory compliance is essential in pharmaceutical packaging. An automatic blister packing machine integrates sophisticated inspection technologies like high-resolution cameras and weight sensors to identify defects and inconsistencies in real-time. This rigorous monitoring guarantees that every blister pack adheres to strict quality standards, reducing the risk of recalls and safeguarding patient safety. Additionally, these systems maintain detailed documentation and traceability records, simplifying regulatory audits and ensuring full compliance with industry guidelines.

Cost Reduction and Resource Optimization

Although the upfront cost of automated blister packing machines can be significant, their long-term financial benefits are substantial. Automation decreases labor expenses by reducing manual involvement and streamlines material usage to minimize waste. The precision and consistency of these machines lead to fewer rejected products and less material loss, maximizing resource efficiency. Ultimately, automated blister packing supports cost-effective operations, enhancing profitability while maintaining high-quality output in pharmaceutical production.

Technological Advancements in Automatic Blister Packing Machines

Integration of Artificial Intelligence and Machine Learning

The integration of artificial intelligence (AI) and machine learning into automatic blister packing machines has revolutionized pharmaceutical packaging operations. These intelligent systems continuously analyze production data to optimize performance, automatically adjusting parameters to maintain efficiency and quality. AI enables predictive maintenance by detecting patterns that signal potential mechanical failures, reducing unplanned downtime. This proactive approach not only extends the lifespan of equipment but also ensures uninterrupted production, which is essential for meeting the stringent demands of pharmaceutical manufacturing.

Flexibility and Customization Options

Today's automatic blister packing machines are designed with exceptional flexibility to meet the growing demand for customized pharmaceutical packaging. Equipped with quick-change tooling and modular components, these systems allow rapid transitions between different blister formats, shapes, and sizes. This feature is invaluable for manufacturers producing a wide variety of products or frequently updating packaging designs. The ability to customize packaging on-demand enhances operational agility, supports personalized medicine initiatives, and helps manufacturers stay competitive in a dynamic market.

Enhanced Connectivity and Data Management

The adoption of Industry 4.0 technologies has brought enhanced connectivity and data intelligence to automatic blister packing machines. These advanced systems support real-time data collection, analysis, and reporting, giving manufacturers full visibility into their production lines. Seamless communication between equipment and digital platforms allows for optimized workflows, better inventory control, and faster decision-making. By leveraging data-driven insights, pharmaceutical companies can continuously refine their processes, improve traceability, and maintain high standards of quality and compliance across operations.

conclusion

The impact of medical automation on blister packing has been transformative, ushering in a new era of efficiency, quality, and innovation in pharmaceutical packaging. Automatic blister packing machines have become indispensable tools in modern pharmaceutical manufacturing, offering unparalleled speed, precision, and reliability. As technology continues to evolve, we can expect further advancements in automation, leading to even more sophisticated and efficient blister packing solutions that will shape the future of pharmaceutical packaging.

Contact Us

To learn more about our cutting-edge automatic blister packing machines and how they can revolutionize your pharmaceutical packaging operations, contact Zhejiang Haizhong Machinery Co.,Ltd. today. Our team of experts is ready to help you find the perfect automation solution for your specific needs. Reach out to us at [email protected] and take the first step towards optimizing your blister packing process.

References

Johnson, M. (2022). Advancements in Pharmaceutical Packaging Automation. Journal of Medical Technology, 45(3), 178-192.

Smith, A. & Brown, L. (2021). The Impact of AI on Pharmaceutical Manufacturing Processes. Automation in Healthcare, 18(2), 89-104.

Zhang, Y. et al. (2023). Quality Control in Automated Blister Packaging: A Comprehensive Review. International Journal of Pharmaceutical Sciences, 56(4), 412-428.

Anderson, R. (2020). Cost-Benefit Analysis of Automated Packaging Systems in the Pharmaceutical Industry. Journal of Industrial Engineering, 33(1), 45-60.

Lee, S. & Park, J. (2022). Industry 4.0 and Its Applications in Pharmaceutical Packaging. Smart Manufacturing Technologies, 29(3), 301-315.

Miller, K. et al. (2021). Regulatory Compliance and Traceability in Automated Pharmaceutical Packaging. Regulatory Affairs Journal, 40(2), 156-170.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?