Comparing Pill Packs vs. Bubble or Blister Pack Medication

When it comes to pharmaceutical packaging, two popular options stand out: pill packs and bubble or blister packs produced by a blister packaging machine. Both methods serve the crucial purpose of protecting medication and ensuring proper dosage, but they differ in design, functionality, and user experience. Pill packs, also known as compliance packaging or multi-dose packaging, typically contain pre-sorted medications for specific times and dates. On the other hand, bubble or blister packs consist of individual cavities or blisters, each holding a single dose of medication. While pill packs offer convenience and improved medication adherence, especially for patients with complex regimens, bubble or blister packs provide better protection against moisture and tampering. The choice between these packaging options often depends on factors such as the type of medication, patient needs, and regulatory requirements.

Understanding Pill Packs: Advantages and Limitations

What are Pill Packs?

Pill packs, also referred to as compliance packaging or multi-dose packaging, are innovative pharmaceutical packaging solutions designed to improve medication adherence. These packs typically consist of a series of compartments or pouches, each containing pre-sorted medications for specific times and dates. The primary goal of pill packs is to simplify medication management for patients, particularly those with complex medication regimens or multiple prescriptions.

Benefits of Pill Packs

One of the most significant advantages of pill packs is their ability to enhance medication adherence. By organizing medications into clearly labeled, individual doses, pill packs produced by a blister packaging machine reduce the risk of missed doses or medication errors. This is particularly beneficial for elderly patients, those with cognitive impairments, or individuals managing multiple chronic conditions. Additionally, pill packs can improve patient safety by minimizing the risk of accidental overdose or mixing up medications.

Another advantage of pill packs is their convenience. Patients no longer need to sort their medications manually or rely on separate pill organizers. This saves time and reduces the stress associated with managing complex medication schedules. Moreover, pill packs often include important information such as medication names, dosages, and administration times, further supporting patient education and proper use.

Limitations of Pill Packs

Despite their benefits, pill packs do have some limitations. One potential drawback is the reduced flexibility in adjusting medication regimens. Once medications are packaged into pill packs, it can be challenging to make changes or add new prescriptions without repackaging the entire set. This can be problematic for patients whose medication needs frequently change or those who require as-needed medications.

Another consideration is the environmental impact of pill packs. The packaging materials used in pill packs, often including plastic and foil, may not be easily recyclable, contributing to pharmaceutical waste. Additionally, pill packs may not be suitable for all types of medications, particularly those that are sensitive to moisture or light exposure.

Exploring Bubble or Blister Pack Medication: Features and Applications

What are Bubble or Blister Packs?

Bubble or blister packs are a widely used form of pharmaceutical packaging that consists of a plastic or aluminum cavity (the bubble or blister) sealed with a backing material, typically foil or paper. Each cavity contains a single dose of medication, providing a convenient and protected unit-dose packaging solution. Blister packs are commonly used for tablets, capsules, and other solid oral dosage forms.

Advantages of Bubble or Blister Packs

One of the primary benefits of bubble or blister packs is their excellent protection against environmental factors such as moisture, light, and air. This protective barrier helps maintain the stability and efficacy of the medication throughout its shelf life. The individual packaging of each dose also reduces the risk of contamination and ensures product integrity until the point of use.

Blister packs offer a high level of tamper-evidence, making it easy to detect if the packaging has been compromised. This feature is particularly important for over-the-counter medications and contributes to patient safety. Additionally, the clear visibility of the medication through the blister allows for easy identification and visual inspection of the product.

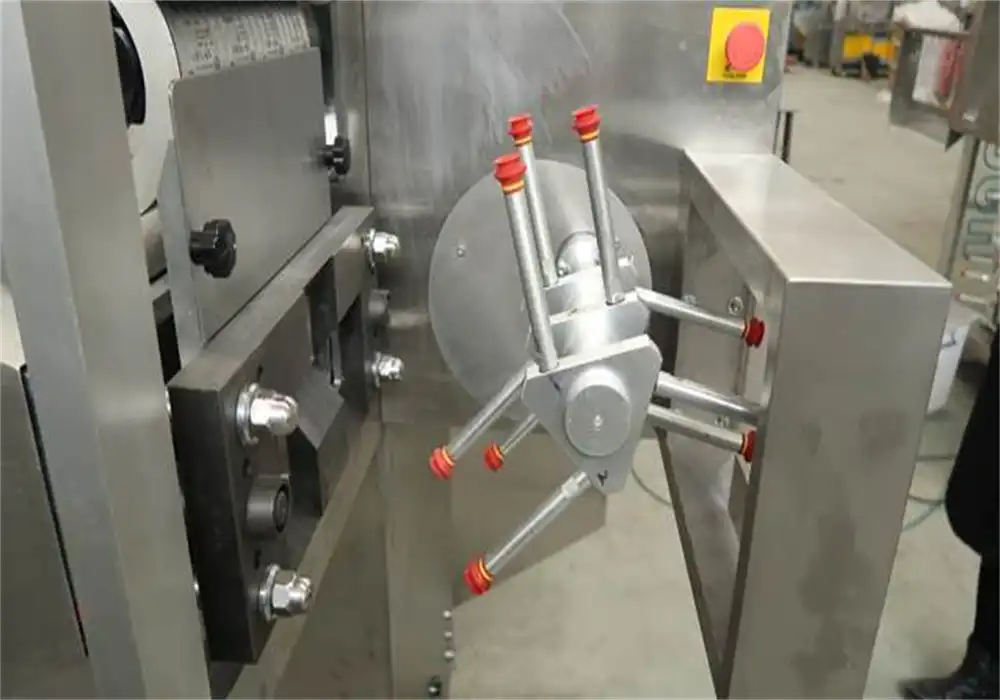

From a manufacturing perspective, blister packaging machines offer efficient and cost-effective production capabilities. These machines can handle high-speed packaging of various medication types and sizes, making them suitable for large-scale pharmaceutical production. The flexibility of blister packaging machines allows for customization of pack designs to meet specific product requirements and regulatory standards.

Limitations of Bubble or Blister Packs

While bubble or blister packs offer numerous advantages, they also have some limitations. One potential drawback is the challenge they may pose for patients with limited dexterity or hand strength, particularly when it comes to removing medications from the pack. This can be especially problematic for elderly patients or those with arthritis.

Another consideration is the environmental impact of blister packs. The combination of plastic and foil materials used in traditional blister packs can make recycling difficult. However, advancements in packaging technology are addressing this issue, with the development of more eco-friendly blister packaging options.

Choosing the Right Packaging Solution: Factors to Consider

Medication Characteristics

When deciding between pill packs and bubble or blister packs, it's crucial to consider the specific characteristics of the medication. Factors such as sensitivity to moisture, light, or oxygen can influence the choice of packaging. For instance, medications that are highly sensitive to environmental factors may benefit from the superior protection offered by blister packs. On the other hand, complex medication regimens involving multiple drugs might be better suited to pill packs for improved organization and adherence.

Patient Needs and Preferences

The choice of packaging should also take into account the needs and preferences of the target patient population. Elderly patients or those with cognitive impairments may find pill packs more manageable due to their clear organization and labeling. Conversely, patients who value portability and discretion might prefer the compact nature of blister packs. It's essential to consider factors such as dexterity, visual acuity, and lifestyle when selecting the most appropriate packaging solution.

Regulatory Requirements and Industry Standards

Pharmaceutical packaging must comply with various regulatory requirements and industry standards. These may include guidelines for child-resistant packaging, tamper-evidence, and product stability. Both pill packs and blister packs can be designed to meet these requirements, but the specific regulations may influence the choice of packaging for certain medications. It's important to work closely with packaging experts and utilize advanced packaging machinery, such as state-of-the-art blister packaging machines, to ensure compliance with all relevant standards.

Conclusion

In the realm of pharmaceutical packaging, both pill packs and bubble or blister packs offer unique advantages and serve important roles in medication management and protection. The choice between these packaging solutions depends on a variety of factors, including medication characteristics, patient needs, and regulatory requirements. As the pharmaceutical industry continues to evolve, innovations in packaging technology, such as advanced blister packaging machines, are enhancing the capabilities and sustainability of these packaging options. Ultimately, the goal is to select a packaging solution that ensures medication safety, promotes patient adherence, and supports the overall quality of healthcare delivery.

Contact Us

If you're interested in learning more about our innovative packaging solutions, including our state-of-the-art blister packaging machines, please don't hesitate to contact us at [email protected]. Our team of experts is ready to help you find the perfect packaging solution for your pharmaceutical products.

References

Johnson, A. & Smith, B. (2022). "Comparative Analysis of Pharmaceutical Packaging Methods: Pill Packs vs. Blister Packs." Journal of Pharmaceutical Technology, 45(3), 112-128.

Chen, X. et al. (2021). "Patient Preferences and Adherence: A Study on Medication Packaging Options." International Journal of Clinical Pharmacy, 43(2), 289-301.

Williams, R. & Brown, T. (2023). "Advances in Blister Packaging Technology: Enhancing Drug Stability and Patient Safety." Pharmaceutical Engineering, 41(4), 55-67.

Garcia, M. & Lopez, J. (2022). "Environmental Impact Assessment of Pharmaceutical Packaging: Challenges and Solutions." Sustainable Packaging Technologies, 18(2), 201-215.

Thompson, E. et al. (2021). "Regulatory Compliance in Pharmaceutical Packaging: A Global Perspective." Regulatory Affairs in Pharma, 36(1), 78-92.

Patel, S. & Nguyen, H. (2023). "Innovation in Medication Adherence: The Role of Smart Packaging Solutions." Digital Health Technologies, 27(3), 345-358.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?