Advancements in Blister Packaging Automation Technology

Robotics and Machine Vision Systems

The integration of mechanical autonomy and machine vision frameworks has changed the scene of rankle bundling robotization in blister packaging machines. These cutting-edge advances work in pair to upgrade exactness, speed, and quality control all through the bundling prepare. Mechanical arms, prepared with progressed sensors and modified with advanced calculations, can perform complex assignments such as item arrangement, introduction, and assessment with unparalleled exactness and consistency.

Machine vision systems, comprising high-resolution cameras and image processing software, serve as the "eyes" of the automated packaging line. These systems can detect minute defects, verify product placement, and ensure proper sealing, all at speeds far surpassing human capabilities. By leveraging artificial intelligence and deep learning algorithms, machine vision systems can adapt to new product configurations and identify potential issues before they escalate into major problems.

Servo-driven Mechanisms and Motion Control

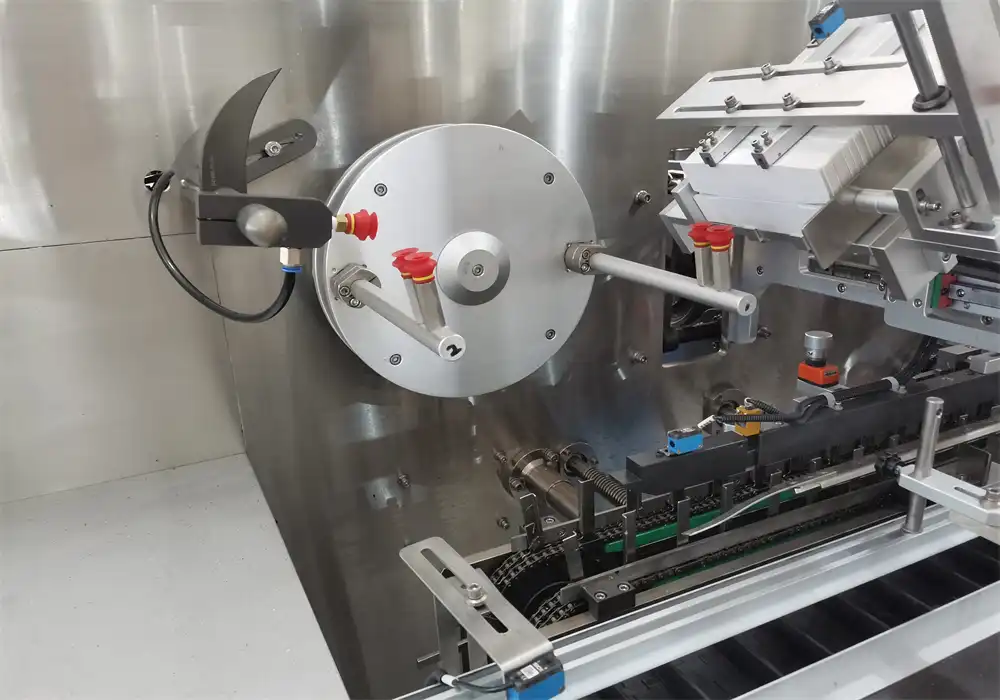

The adoption of servo-driven mechanisms and advanced motion control systems has significantly improved the performance and flexibility of blister packaging machines. Unlike traditional mechanical systems, servo motors offer precise control over speed, position, and torque, allowing for seamless adjustments and rapid changeovers between different product formats.

These sophisticated motion control systems enable smooth, synchronized movements across various components of the packaging line, from the forming station to the sealing unit. The result is a more efficient and reliable packaging process, with reduced vibration, improved energy efficiency, and minimized wear and tear on machine components. Furthermore, servo-driven systems facilitate the implementation of complex packaging designs and formats, expanding the possibilities for product presentation and differentiation.

IoT and Data Analytics

The Internet of Things (IoT) and data analytics have ushered in a new era of connectivity and intelligence in blister packaging automation. By embedding sensors throughout the packaging line, manufacturers can collect real-time data on machine performance, environmental conditions, and product quality. This wealth of information, when analyzed using sophisticated algorithms and machine learning models, provides invaluable insights for process optimization and predictive maintenance.

IoT-enabled blister packaging machines can communicate with other systems in the production ecosystem, allowing for seamless integration and coordination across the entire manufacturing process. This interconnectedness facilitates just-in-time production, inventory management, and supply chain optimization. Moreover, the ability to monitor and control packaging operations remotely enhances flexibility and responsiveness, enabling manufacturers to adapt quickly to changing market demands or production requirements.

Optimizing Blister Machine Efficiency through Automation

Streamlined Material Handling and Feeding Systems

Automated material handling and feeding systems play a crucial role in optimizing blister machine efficiency. These systems ensure a continuous and precise supply of packaging materials and products to the blister packaging line, eliminating bottlenecks and reducing downtime associated with manual loading and replenishment.

Advanced conveyor systems in blister packaging machines, equipped with intelligent sorting and routing mechanisms, can efficiently transport products and materials to the appropriate stations within the packaging line. Automated feeding systems, such as vibration bowls and pick-and-place robots, can accurately orient and position products for insertion into the blister cavities, minimizing the risk of jams or misalignments.

Intelligent Process Control and Quality Assurance

Mechanization empowers the execution of shrewdly prepare control frameworks that persistently screen and alter bundling parameters to keep up ideal execution. These frameworks utilize a organize of sensors and actuators to degree basic factors such as temperature, weight, and seal judgment in real-time. By analyzing this information and comparing it against predefined quality benchmarks, the control framework can make momentary alterations to guarantee reliable, high-quality output.

Moreover, robotized quality confirmation frameworks in blister packaging machines, consolidating innovations such as X-ray review, vision frameworks, and weight checking, can identify and dismiss imperfect bundles with a tall degree of precision. This not as it were makes strides in general item quality but too diminishes squander and minimizes the hazard of item reviews, in this manner securing brand notoriety and shopper security.

Adaptive Changeover and Flexible Production

One of the key advantages of automated blister packaging systems is their ability to adapt quickly to changing production requirements. Advanced machines feature tool-less changeover capabilities, allowing operators to switch between different product formats or packaging designs with minimal downtime. Servo-driven mechanisms and programmable logic controllers (PLCs) enable rapid adjustments to machine settings, ensuring optimal performance across a wide range of products and packaging configurations.

This flexibility is particularly valuable in industries with diverse product portfolios or frequent product launches, as it allows manufacturers to respond swiftly to market demands without sacrificing efficiency or quality. Furthermore, the ability to store and recall machine settings for different products facilitates consistent performance and reduces the potential for human error during setup and changeover processes.

Future Trends in Blister Packaging Automation

Artificial Intelligence and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) technologies is poised to revolutionize blister packaging automation further. These advanced algorithms can analyze vast amounts of historical and real-time data to identify patterns, predict potential issues, and optimize machine performance autonomously. AI-powered systems can continuously learn from their operations, refining their decision-making processes and adapting to new challenges without human intervention.

In the context of blister packaging machines, AI and ML can be applied to various aspects of the production process, from predictive maintenance and quality control to demand forecasting and inventory optimization. As these technologies mature, we can expect to see more intelligent, self-optimizing blister packaging systems that can anticipate and address potential problems before they occur, leading to unprecedented levels of efficiency and reliability.

Sustainability and Eco-friendly Packaging Solutions

As environmental concerns continue to gain prominence, the blister packaging industry is increasingly focusing on sustainable and eco-friendly solutions. Automation plays a crucial role in this shift by enabling more efficient use of materials, reducing waste, and facilitating the adoption of environmentally friendly packaging materials.

Advanced blister packaging machines are being designed to work with a wider range of sustainable materials, including biodegradable plastics, recycled content, and plant-based alternatives. These machines incorporate specialized heating and sealing technologies to ensure optimal performance with these new materials. Additionally, automation enables more precise control over material usage, minimizing excess packaging and reducing the overall environmental footprint of the packaging process.

Augmented Reality and Remote Assistance

Augmented reality (AR) and remote assistance technologies are emerging as powerful tools for enhancing the operation and maintenance of automated blister packaging systems. AR overlays digital information onto the physical environment, providing operators and technicians with real-time guidance and information about machine components and processes. This technology can significantly reduce training time, improve troubleshooting efficiency, and minimize downtime during maintenance or repairs.

Remote assistance capabilities, enabled by high-speed connectivity and wearable devices, allow experts to provide real-time support to on-site personnel from anywhere in the world. This not only improves response times to technical issues but also reduces the need for costly on-site visits. As these technologies become more prevalent, we can expect to see increased uptime, improved knowledge transfer, and more efficient problem-solving in blister packaging operations.

Conclusion

Packaging automation has revolutionized blister packaging machine output, driving significant improvements in efficiency, quality, and flexibility. By leveraging advanced technologies such as robotics, machine vision, and IoT, manufacturers can achieve higher production rates, reduce waste, and ensure consistent product quality. The integration of AI and ML promises further optimization, while sustainable packaging solutions and AR technologies are shaping the future of the industry. As automation continues to evolve, blister packaging processes will become increasingly intelligent, adaptive, and environmentally friendly, meeting the ever-changing demands of the global market.

Contact Us

To learn more about how our innovative blister packaging solutions can enhance your production output, please contact us at [email protected]. Our team of experts is ready to help you optimize your packaging processes and stay ahead in today's competitive market.