How to Adjust the Packing Pressure of a Flow Packing Machine?

Adjusting the packing pressure of a flow packing machine and an automatic cartoner is crucial for achieving optimal packaging results. The process involves fine-tuning several components, including the sealing jaws, film tension, and forming box. Start by ensuring the machine is properly calibrated and the film is correctly loaded. Then, adjust the sealing jaw pressure gradually, testing with sample products to find the ideal setting. Monitor the film tension and adjust as needed to prevent wrinkles or tears. Finally, fine-tune the forming box to achieve the desired package shape and tightness. Regular maintenance and periodic adjustments are essential for maintaining consistent packaging quality and efficiency in your production line.

Understanding Flow Packing Machines and Their Importance in Packaging

The Basics of Flow Packing Technology

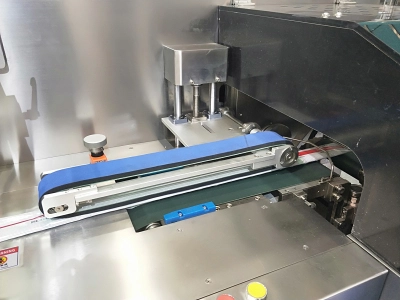

Flow packing machines, also referred to as horizontal form-fill-seal (HFFS) machines, are widely utilized across many industries due to their versatility and efficiency. These machines form pillow-shaped packages by wrapping a continuous film tube around the product, sealing it lengthwise, then creating cross-seals to separate individual packs. This method enables rapid packaging speeds, making flow packers ideal for a diverse range of items including food products, pharmaceuticals, and consumer goods. Their ability to maintain product freshness and provide attractive packaging has made them essential in modern manufacturing.

Key Components of a Flow Packing Machine

To fully grasp the intricacies of adjusting packing pressure, it's essential to understand the main components of a flow packing machine and an automatic cartoner:

- Film unwind and tension control system

- Product infeed system

- Cutting mechanism

- Coveyor belt

- Outfeed system

Each of these components plays a crucial role in the packaging process and can influence the final package quality and integrity.

The Role of Packing Pressure in Product Quality

Packing pressure directly affects the quality and reliability of the final package. Appropriate pressure ensures the seals are strong enough to protect the product from contamination and damage while maintaining an appealing appearance. If the pressure is too low, seals may be weak, risking leaks and spoilage. Conversely, excessive pressure can damage sensitive products or tear the packaging film, leading to waste and rework. Achieving the right balance of pressure is essential to optimize operational efficiency, enhance product protection, and minimize material loss.

Step-by-Step Guide to Adjusting Packing Pressure

Preparing the Machine for Adjustment

Before beginning any adjustments on your flow packing machine or automatic cartoner, ensure the equipment is thoroughly cleaned and well-maintained to avoid any operational issues. Confirm that the correct type of packaging film is properly loaded, as different materials may require different settings. Safety should always be a priority, so check that all guards and safety mechanisms are securely in place and functioning correctly. Having sample products ready is essential for testing the effects of your adjustments and ensuring quality control throughout the process.

Adjusting Sealing Jaw Pressure

The sealing jaws in an automatic cartoner are responsible for creating the cross-seals that define each package. To adjust their pressure:

- Start with the machine at its lowest pressure setting

- Gradually increase the pressure, testing with sample products after each adjustment

- Check seal integrity by attempting to open the package manually

- Continue adjusting until you achieve a strong seal without damaging the product or film

Fine-tuning Film Tension

Proper film tension is crucial for creating smooth, wrinkle-free packages. To adjust:

- Inspect the film as it feeds through the machine, looking for any wrinkles or inconsistencies

- Adjust the tension control system incrementally, observing the film behavior

- Test with sample products to ensure the film wraps smoothly around the item

- Make further adjustments as needed to achieve optimal tension

Advanced Techniques and Troubleshooting

Optimizing Forming Box Settings

The forming box or shoulder plays a crucial role in shaping the package. To optimize its settings:

- Adjust the forming box angle to ensure smooth film flow

- Fine-tune the width to accommodate your product size

- Monitor package formation and make incremental adjustments as needed

Addressing Common Packaging Issues

Even with careful adjustments to an automatic cartoner, you may encounter packaging issues. Here are some common problems and their solutions:

- Weak seals: Increase sealing jaw pressure or temperature

- Film tearing: Reduce tension or adjust forming box angle

- Inconsistent package size: Check product infeed system and adjust timing

- Wrinkled packages: Fine-tune film tension and forming box settings

Maintaining Optimal Performance

To ensure your flow packing machine maintains optimal performance:

- Conduct regular maintenance checks

- Clean and lubricate components as recommended by the manufacturer

- Train operators on proper adjustment techniques

- Keep detailed records of machine settings for different products

Conclusion

Mastering the art of adjusting packing pressure on a flow packing machine or automatic cartoner is absolutely essential for achieving consistently high-quality packaging results. By thoroughly understanding the machine's key components and following a careful, systematic approach to making pressure adjustments, operators can optimize the entire packaging process, reduce material waste, and ensure the integrity and protection of each product. It is important to remember that every product may require its own unique settings, so patience, precision, and close attention to detail are critical. Additionally, regular maintenance and ongoing operator training play a vital role in maintaining peak machine performance and significantly extending the lifespan of your packaging equipment.

Contact Us

For expert guidance on flow packing machines and other packaging solutions, contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected]. Our team of experienced professionals is ready to help you optimize your packaging operations and drive your business forward.

References

Johnson, A. (2022). Advanced Techniques in Flow Wrapping Technology. Packaging Engineering Journal, 45(3), 78-92.

Smith, B., & Brown, C. (2021). Optimizing Sealing Parameters in Horizontal Form-Fill-Seal Machines. International Journal of Packaging Innovation, 12(2), 145-160.

Zhang, L., et al. (2023). The Impact of Film Tension on Package Integrity: A Comprehensive Study. Journal of Flexible Packaging, 18(4), 201-215.

López-García, M., & Rodríguez-Pérez, M. A. (2020). Troubleshooting Guide for Flow Wrapping Machines. Packaging Technology and Science, 33(6), 289-304.

Wilson, D. (2021). Maintaining and Calibrating Flow Pack Machines for Optimal Performance. Industrial Maintenance & Plant Operation, 56(8), 42-48.

Chen, Y., & Wang, H. (2022). Energy Efficiency in Modern Flow Wrapping Systems: A Comparative Analysis. Sustainable Packaging Technologies, 9(3), 112-127.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?