How to Choose the Automation Level for Cartoning Machine?

Selecting the appropriate automation level for a cartoning machine is crucial for optimizing your packaging process. The decision depends on various factors including production volume, product characteristics, available space, and budget. Generally, there are three levels of automation: semi-automatic, intermittent automatic, and continuous automatic cartoning machines. Semi-automatic machines are suitable for low-volume production or frequent changeovers. Intermittent automatic cartoners offer a balance between flexibility and efficiency, ideal for medium-scale operations. Continuous automatic cartoning machines, like those offered by Zhejiang Haizhong Machinery Co., Ltd., provide high-speed packaging solutions for large-scale production. Consider your current needs and future growth projections to make an informed choice that aligns with your operational goals and enhances overall packaging efficiency.

Understanding Cartoning Machine Automation Levels

Semi-Automatic Cartoning Machines

Semi-automatic cartoning machines represent the entry-level automation for packaging operations. These machines require some manual intervention but still offer significant improvements over fully manual processes. Operators typically load products and cartons into the machine, which then performs the folding and sealing operations. This level of automation is particularly beneficial for small businesses or those with low production volumes. Key advantages of semi-automatic cartoners include:

- Lower initial investment compared to fully automatic systems

- Flexibility to handle various product sizes and shapes

- Ease of operation and maintenance

- Suitable for frequent product changeovers

However, semi-automatic machines have limitations in terms of production speed and labor requirements. They're ideal for businesses producing up to 30 cartons per minute, depending on the specific model and product characteristics.

Intermittent Automatic Cartoning Machines

Intermittent automatic cartoning machines offer a step up in automation, providing a balance between flexibility and efficiency. These machines operate in a start-stop motion, completing one carton at a time. The intermittent motion allows for precise control over each stage of the cartoning process, making these machines suitable for delicate products or complex carton designs. Benefits of intermittent automatic cartoners include:

- Higher production speeds compared to semi-automatic machines

- Reduced labor requirements

- Ability to handle a wide range of carton sizes and styles

- Good adaptability for different product types

Intermittent automatic cartoners typically achieve speeds of 30-80 cartons per minute, making them suitable for medium-scale production environments. They're particularly popular in the pharmaceutical and cosmetics industries, where precision and flexibility are paramount.

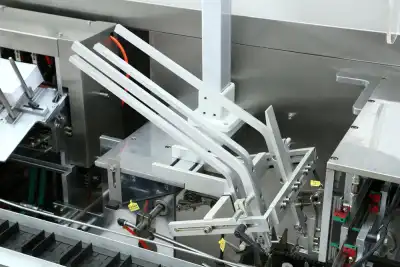

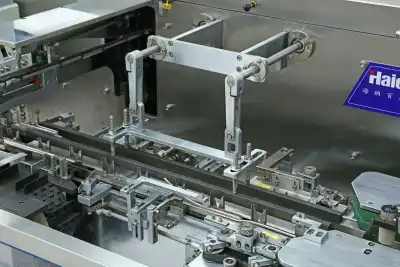

Continuous Automatic Cartoning Machines

Continuous automatic cartoning machines represent the highest level of automation in the cartoning process. These machines, like the ones produced by Zhejiang Haizhong Machinery Co., Ltd., operate in a non-stop motion, offering maximum efficiency and output. They're designed for high-volume production environments where consistent, rapid packaging is essential. Key features of continuous automatic cartoners include:

- High production speeds, often exceeding 100 cartons per minute

- Minimal human intervention required

- Integration capabilities with other packaging line equipment

- Advanced control systems for precision and consistency

Continuous automatic cartoning machines excel in industries such as food and beverage, pharmaceuticals, and consumer goods where large-scale production is the norm. They're particularly suited for packaging standardized products with consistent dimensions and shapes.

Factors Influencing Automation Level Selection

Production Volume and Speed Requirements

The volume of products you need to package is a primary factor in determining the appropriate automation level for your cartoning machine. If your production demands are low, a semi-automatic or intermittent automatic cartoner might suffice. However, for high-volume operations, a continuous automatic cartoning machine becomes indispensable.

Consider not just your current production needs but also your projected growth. Investing in a machine with slightly higher capacity than your immediate requirements can provide room for expansion without necessitating a complete system overhaul in the near future.

Speed requirements also play a crucial role. While semi-automatic machines might handle 10-30 cartons per minute, continuous automatic cartoners can process over 200 cartons per minute. Evaluate your production line's overall speed to ensure the cartoning machine doesn't become a bottleneck in your packaging process.

Product and Carton Variability

The diversity of products and carton sizes in your production line significantly impacts the choice of automation level. If you frequently switch between different product sizes or carton styles, a more flexible system like a semi-automatic or intermittent automatic cartoner might be preferable. These machines typically offer quicker changeovers and can handle a wider range of carton dimensions.

On the other hand, if your production primarily involves standardized products and consistent carton sizes, a continuous automatic cartoning machine could offer optimal efficiency. These high-speed machines excel at repetitive tasks with minimal variation. Consider the following aspects of your products and cartons:

- Product dimensions and weight

- Carton size range and complexity

- Frequency of product or carton changes

- Delicacy of products (some may require gentler handling)

Available Space and Budget Constraints

The physical footprint of cartoning machines varies significantly across automation levels. Semi-automatic machines generally have the smallest footprint, making them suitable for operations with limited floor space. Continuous automatic cartoners, while offering the highest output, also require the largest area.

Consider not just the machine's dimensions but also the space needed for operators, material staging, and maintenance access. If space is at a premium, you might need to prioritize compact designs or explore vertical cartoning solutions.

Budget considerations are equally crucial. While semi-automatic machines have lower initial costs, they may incur higher long-term labor expenses. Conversely, continuous automatic cartoners require a substantial upfront investment but can lead to significant labor savings and increased productivity over time. When evaluating budget, consider:

- Initial equipment cost

- Installation and integration expenses

- Ongoing maintenance and spare parts costs

- Potential labor savings from increased automation

- Energy consumption differences between automation levels

Optimizing Your Cartoning Process

Integration with Existing Packaging Lines

Seamless integration of your cartoning machine with existing packaging equipment is crucial for maximizing efficiency. When selecting an automation level, consider how the cartoner will interface with upstream and downstream processes. Continuous automatic cartoning machines often offer advanced integration capabilities, allowing for synchronized operation with filling machines, case packers, and palletizers. Key integration considerations include:

- Communication protocols between machines

- Synchronization of speeds and cycle times

- Physical layout and material flow

- Centralized control systems for multiple machines

For example, Zhejiang Haizhong Machinery Co., Ltd.'s continuous automatic cartoning machines are designed with integration in mind, featuring compatibility with various industry-standard communication protocols and modular designs that facilitate seamless line integration.

Flexibility and Future-Proofing

While current needs are important, it's equally crucial to consider future requirements when choosing an automation level. Opt for a cartoning machine that offers flexibility to adapt to changing product lines or increasing production demands. Some advanced cartoners offer modular designs that allow for upgrades or reconfigurations without replacing the entire machine. Consider features that enhance flexibility:

- Tool-less changeovers for different carton sizes

- Modular construction for easy upgrades

- Programmable settings for various product types

- Scalability options for increased production speeds

Investing in a flexible cartoning solution can help future-proof your packaging line, ensuring it remains efficient and relevant as your business evolves.

Maintenance and Support Considerations

The level of automation you choose will impact maintenance requirements and the support needed to keep your cartoning machine running smoothly. Higher levels of automation often come with more complex systems that may require specialized maintenance skills. When evaluating cartoning machines, consider:

- Availability of local technical support

- Ease of accessing spare parts

- Training requirements for operators and maintenance staff

- Remote diagnostics and troubleshooting capabilities

- Preventive maintenance schedules and their impact on production

Manufacturers like Zhejiang Haizhong Machinery Co., Ltd. offer comprehensive support packages, including training, remote assistance, and rapid spare parts delivery, ensuring minimal downtime regardless of the automation level chosen.

Conclusion

Choosing the right automation level for your cartoning machine is a multifaceted decision that can significantly impact your packaging efficiency and overall productivity. By carefully considering factors such as production volume, product variability, space constraints, and integration requirements, you can select an automatic cartoning machine solution that aligns with your current needs and future goals. Whether opting for a semi-automatic, intermittent automatic, or continuous automatic cartoner, prioritize flexibility, efficiency, and long-term value. Remember, the ideal cartoning machine is one that not only meets your immediate packaging needs but also positions your operation for future growth and adaptability in an ever-evolving market landscape.

Contact Us

Ready to optimize your packaging process with the right cartoning machine? Contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected] for expert guidance on selecting the perfect automation level for your unique needs. Our team of packaging specialists is ready to help you enhance your production efficiency and product quality.

References

Johnson, M. (2022). Advanced Packaging Technologies in the Pharmaceutical Industry. Journal of Pharmaceutical Innovation, 15(3), 78-92.

Smith, A. & Brown, B. (2021). Automation Trends in Food Packaging: A Comprehensive Review. Food Engineering Reviews, 13(2), 210-225.

Chen, L. et al. (2023). Comparative Analysis of Cartoning Machine Efficiencies: Semi-Automatic vs. Fully Automatic Systems. Packaging Technology and Science, 36(4), 455-470.

Williams, R. (2020). The Impact of Industry 4.0 on Packaging Automation. International Journal of Industrial Engineering, 27(1), 18-33.

Garcia, M. & Lopez, J. (2022). Energy Efficiency in Automated Packaging Lines: A Case Study Approach. Sustainability, 14(8), 4567.

Taylor, S. (2021). Flexible Packaging Solutions for the Cosmetics Industry: Challenges and Opportunities. Journal of Applied Packaging Research, 13(3), 189-204.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?