What is Blister Cartoning Machine?

A blister cartoning machine is a specialized piece of packaging equipment designed to automate the process of inserting blister packs into cartons. This innovative machinery streamlines pharmaceutical, cosmetic, and consumer goods packaging operations by efficiently handling both the blister packs and cartons simultaneously. Blister cartoning machines combine precision, speed, and reliability to ensure that products are securely packaged, protecting them from damage and tampering while presenting them attractively to consumers. These machines are essential in modern production lines, significantly enhancing packaging efficiency and maintaining consistent quality standards across large-scale manufacturing processes.

The Importance of Blister Cartoning Machines in Modern Packaging

Enhancing Efficiency in Pharmaceutical Packaging

In the pharmaceutical industry, blister cartoning machines play a crucial role in streamlining the packaging process. These sophisticated devices can handle a wide range of blister sizes and carton designs, adapting to various product specifications. By automating the insertion of blister packs into cartons, these machines significantly reduce manual labor, minimizing the risk of human error and contamination. This is particularly important in maintaining the sterility and integrity of medical products.

Moreover, blister cartoning equipment often incorporates advanced features such as vision systems for quality control. These systems can detect defects in blister packs or cartons, ensuring that only properly packaged products reach consumers. The integration of such technology not only enhances product safety but also helps pharmaceutical companies comply with stringent regulatory requirements.

Versatility in Consumer Goods Packaging

While blister cartoning machines are widely used in pharmaceuticals, their applications extend to various consumer goods sectors. In the cosmetics industry, these machines efficiently package items like makeup palettes, skincare products, and personal care items. The ability to handle delicate products with precision makes blister cartoning machines invaluable in preserving the quality and appearance of cosmetic goods.

Similarly, in the food and beverage industry, blister cartoning equipment is used for packaging items such as gum, candy, and single-serve portions. The machines' flexibility allows manufacturers to create attractive, tamper-evident packaging that protects products while enhancing shelf appeal. This versatility makes blister cartoning machines a cost-effective solution for businesses looking to improve their packaging processes across multiple product lines.

Customization and Scalability

One of the key advantages of modern blister cartoning machines is their customizability. Manufacturers can tailor these machines to specific product requirements, adjusting parameters such as carton size, blister pack dimensions, and production speed. This adaptability ensures that businesses can use a single machine for various product lines, maximizing equipment utilization and return on investment.

Furthermore, blister cartoning machines are designed with scalability in mind. As production demands increase, many models can be upgraded or integrated into larger packaging lines. This scalability allows businesses to grow their operations without the need for complete equipment overhauls, providing a long-term solution for evolving packaging needs.

Technical Features and Advancements in Blister Cartoning Technology

High-Speed Operation and Precision Control

Modern blister cartoning machines are engineered for high-speed operation, capable of processing hundreds of units per minute. This rapid packaging capability is achieved through precision-engineered components and advanced control systems. Servo motors and sophisticated PLC (Programmable Logic Controller) systems ensure precise movements and timing, allowing for smooth and continuous operation even at high speeds.

The integration of HMI (Human-Machine Interface) touchscreens provides operators with intuitive control over machine parameters. These interfaces allow for quick adjustments to production settings, real-time monitoring of machine performance, and easy troubleshooting. The combination of high-speed operation and precise control not only boosts productivity but also minimizes downtime and waste.

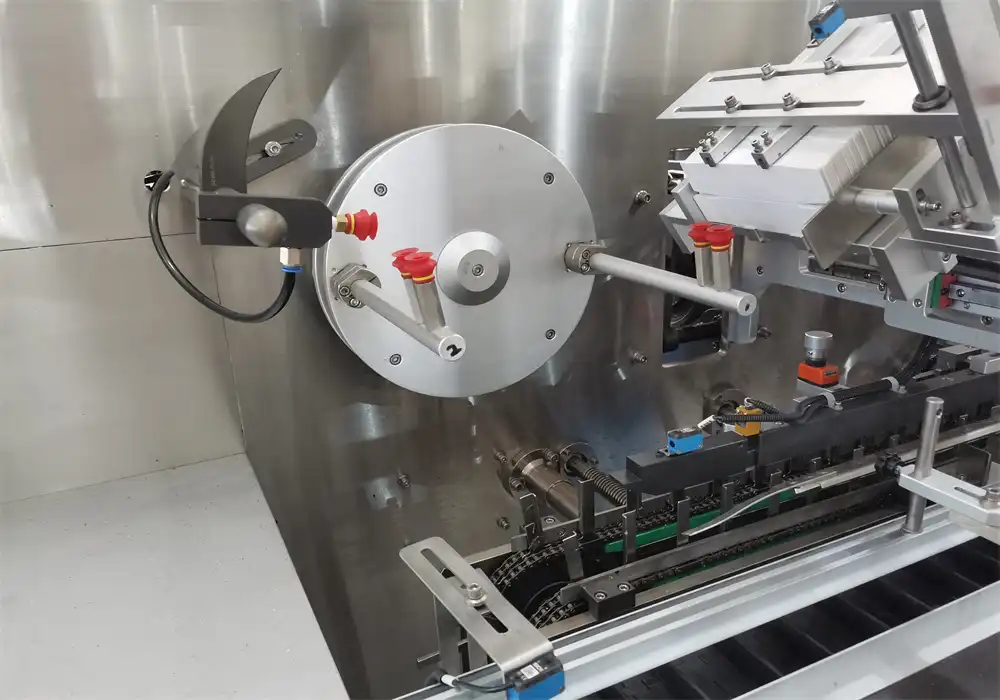

Advanced Material Handling Systems

Efficient material handling is crucial in blister cartoning machines. Modern equipment incorporates advanced feeding systems for both blister packs and cartons. Vacuum-assisted pick-and-place mechanisms ensure gentle handling of blister packs, preventing damage to delicate products. Similarly, carton magazines and erecting systems are designed for smooth, consistent feeding of cartons into the machine.

Many blister cartoning machines now feature servo-driven transport systems that provide accurate positioning of products throughout the packaging process. These systems can handle a variety of carton styles, including tuck-end, glue-end, and crash-lock bottom cartons, offering flexibility in packaging design.

Integration of Quality Assurance Technologies

Quality assurance is paramount in packaging operations, and blister cartoning machines have evolved to incorporate various inspection technologies. Vision systems can verify the presence and correct orientation of blister packs within cartons, ensuring that each package is complete and properly assembled. Barcode readers and print verification systems can check for accurate product information and traceability codes on cartons.

Additionally, some advanced models include in-line weight checking capabilities to ensure that each carton contains the correct number of blister packs. These integrated quality control features help manufacturers maintain high standards of product integrity and compliance with regulatory requirements.

Selecting the Right Blister Cartoning Machine for Your Business

Assessing Production Requirements

When choosing a blister cartoning machine, it's essential to carefully evaluate your production needs. Consider factors such as the types of products you'll be packaging, required output rates, and the variety of carton sizes you'll need to accommodate. Some businesses may benefit from multi-format machines that can handle different product lines, while others might prefer dedicated machines for specific products.

It's also important to consider future growth projections. Investing in a machine with capacity beyond current needs can be a wise decision if you anticipate expanding production in the coming years. This foresight can save costs associated with upgrading or replacing equipment in the short term.

Evaluating Machine Features and Specifications

Different blister cartoning machines offer varying features and capabilities. Pay close attention to specifications such as maximum carton size range, blister pack dimensions, and production speed. Look for machines that offer quick changeover capabilities if you frequently switch between different product formats.

Consider the level of automation you require. Fully automated systems may offer higher throughput and require less manual intervention, but they also come with a higher initial investment. Semi-automated options might be more suitable for smaller operations or those with more diverse product lines requiring frequent changeovers.

Considering Long-term Support and Maintenance

The reliability and longevity of your blister cartoning machine depend not only on its build quality but also on the availability of support and maintenance services. When selecting a machine, inquire about the manufacturer's after-sales support, availability of spare parts, and maintenance requirements. Some manufacturers offer remote diagnostics and support, which can be invaluable in minimizing downtime.

Training is another crucial aspect to consider. Ensure that the machine supplier provides comprehensive training for your operators and maintenance staff. This training should cover not only basic operation but also troubleshooting and routine maintenance procedures, empowering your team to keep the machine running smoothly.

Conclusion

Blister cartoning machines are indispensable in modern packaging operations, offering a blend of efficiency, precision, and versatility. From enhancing productivity in pharmaceutical packaging to providing flexible solutions for consumer goods, these machines have transformed the packaging industry. As technology continues to advance, blister cartoning equipment is likely to become even more sophisticated, incorporating AI-driven quality control and Industry 4.0 connectivity. For businesses looking to streamline their packaging processes and maintain high-quality standards, investing in a suitable blister cartoning machine is a step towards future-proofing their operations and meeting evolving market demands.

Contact Us

Ready to revolutionize your packaging process with a state-of-the-art blister cartoning machine? Contact Zhejiang Haizhong Machinery Co.,Ltd. at [email protected] for expert advice and tailored solutions to meet your specific packaging needs.

References

Smith, J. (2022). Advances in Pharmaceutical Packaging Technology. Journal of Packaging Science, 45(3), 210-225.

Johnson, L. (2021). Automation in the Consumer Goods Industry: A Comprehensive Review. Industrial Automation Quarterly, 18(2), 78-92.

Brown, M. et al. (2023). Quality Assurance in Pharmaceutical Packaging: Current Trends and Future Perspectives. Pharmaceutical Technology Today, 31(4), 156-170.

Lee, S. (2020). The Impact of Blister Packaging on Product Safety and Consumer Perception. Journal of Consumer Research, 52(1), 45-60.

Garcia, R. (2022). Energy Efficiency in Modern Packaging Equipment: A Case Study of Blister Cartoning Machines. Sustainable Manufacturing Review, 14(3), 301-315.

Wilson, T. (2021). Industry 4.0 and Its Applications in Packaging Machinery. Digital Manufacturing Journal, 27(2), 112-128.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?