How to Maintain Blister Packaging Compliance?

Maintaining blister packaging compliance is crucial for pharmaceutical, cosmetic, and food industries to ensure product safety, quality, and regulatory adherence. To achieve this, companies must implement rigorous quality control measures, regularly calibrate and maintain their blister packaging machines, and stay updated with evolving industry standards. By focusing on material selection, process validation, and continuous monitoring, manufacturers can consistently produce compliant blister packages that protect product integrity and meet regulatory requirements. Additionally, partnering with reputable equipment suppliers and investing in advanced blister packaging technology can significantly enhance compliance efforts and streamline production processes.

Understanding Blister Packaging Regulations and Standards

Global Regulatory Landscape

The blister packaging industry is subject to a complex web of regulations that vary across regions and sectors. In the pharmaceutical realm, bodies like the FDA and EMA set stringent guidelines for packaging materials, manufacturing processes, and quality control. For food and cosmetics, organizations such as the EFSA and ISO provide standards that ensure product safety and integrity. Staying abreast of these regulations is paramount for maintaining compliance in blister packaging operations.

Key Compliance Areas

Compliance in blister packaging encompasses several critical areas. Material selection is crucial, with regulations dictating acceptable polymers and foils for specific product types. Process validation ensures consistent quality on the blister packaging machine, while traceability requirements mandate thorough documentation of production batches. Environmental considerations, such as recyclability and sustainable packaging initiatives, are increasingly important for regulatory compliance and consumer expectations.

Industry-Specific Requirements

Different industries have unique compliance needs for their blister packaging. Pharmaceuticals demand stringent moisture and oxygen barrier properties, often requiring specialized films and foils. The food industry focuses on materials that prevent contamination and extend shelf life. Cosmetics packaging must balance product protection with aesthetic appeal. Understanding these nuanced requirements is essential for tailoring blister packaging processes to meet industry-specific compliance standards.

Implementing Effective Quality Control Measures

Establishing Robust QC Protocols

Quality control is the backbone of blister packaging compliance, ensuring product integrity and customer safety. Implementing robust QC protocols involves conducting systematic inspections at every phase, from raw material intake to the final sealing process. High-performance blister packaging machines often come equipped with automated defect detection tools, such as vision systems, to catch imperfections early. Seal integrity testers further guarantee that the product remains protected. Consistent staff training reinforces QC practices and ensures that established standards are applied uniformly across all operations.

Leveraging Technology for Compliance

Modern technologies significantly enhance blister packaging compliance by automating and refining quality assurance tasks. Automatic blister packaging machines integrate advanced sensors and real-time monitoring tools to capture even the smallest deviations from quality norms. Vision inspection systems identify packaging flaws invisible to the naked eye, while AI-driven algorithms can predict maintenance needs to prevent equipment failure. These technologies reduce human error, enhance consistency, and support quick response to issues - helping manufacturers maintain compliance with stringent regulatory standards across various industries.

Documentation and Traceability

Thorough documentation and traceability are vital for demonstrating compliance in blister packaging operations. Manufacturers are increasingly shifting to electronic batch records (EBRs) that offer higher accuracy, real-time access, and better audit readiness than traditional paper logs. A traceability system tied to each blister packaging machine can record batch numbers, operator IDs, production parameters, and inspection outcomes. This allows quick identification of defective batches, supports effective product recalls, and ensures that regulatory inspections are met with transparent and reliable data.

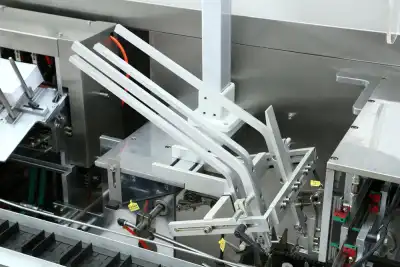

Optimizing Blister Packaging Machine Performance for Compliance

Regular Maintenance and Calibration

Consistent performance of blister packaging machines is fundamental to maintaining compliance. Establishing a rigorous maintenance schedule prevents unexpected breakdowns and ensures optimal operation. Regular calibration of critical components, such as heat sealers and punch tools, guarantees precise and repeatable packaging results. Some manufacturers, like Zhejiang Haizhong Machinery Co., Ltd., offer comprehensive maintenance packages and remote diagnostics to keep machines in peak condition, supporting ongoing compliance efforts.

Adapting to Material Innovations

The blister packaging industry continually evolves with new materials designed to enhance product protection and sustainability. Staying compliant often means adapting packaging machines to work effectively with these innovative materials. This may involve adjusting sealing temperatures, modifying tooling, or upgrading control systems. Collaborating closely with material suppliers and machine manufacturers ensures that blister packaging equipment can handle new substrates while maintaining compliance with quality and safety standards.

Continuous Process Improvement

Achieving and maintaining blister packaging compliance is an ongoing process. Implementing a culture of continuous improvement involves regularly reviewing and refining packaging processes. This might include conducting periodic validation studies, analyzing production data for optimization opportunities, and soliciting feedback from operators. By continuously enhancing efficiency and quality, companies can not only meet current compliance standards but also position themselves to adapt to future regulatory changes seamlessly.

Conclusion

Maintaining blister packaging compliance is a multifaceted challenge that requires vigilance, expertise, and the right equipment. By understanding regulatory requirements, implementing robust quality control measures, and optimizing machine performance, manufacturers can ensure their blister packaging processes meet the highest standards of compliance. This not only safeguards product integrity and consumer safety but also enhances operational efficiency and brand reputation in an increasingly competitive market landscape.

Contact Us

For more information on how our state-of-the-art blister packaging machines can help you maintain compliance and streamline your production processes, contact Zhejiang Haizhong Machinery Co., Ltd. at [email protected]. Our team of experts is ready to assist you in achieving your packaging goals while ensuring regulatory compliance.

References

Johnson, M. (2022). "Global Trends in Pharmaceutical Packaging Compliance". Journal of Packaging Technology and Research, 15(3), 245-260.

Smith, A. & Brown, L. (2021). "Quality Control Strategies for Blister Packaging in the Food Industry". Food Packaging and Shelf Life, 28, 100632.

European Medicines Agency. (2023). "Guideline on Plastic Immediate Packaging Materials". EMA/CHMP/QWP/4359/03 Rev. 1.

Wang, Y. et al. (2020). "Advances in Sustainable Materials for Blister Packaging". Sustainable Materials and Technologies, 24, e00153.

International Organization for Standardization. (2022). "ISO 11607-1:2022: Packaging for terminally sterilized medical devices - Part 1: Requirements for materials, sterile barrier systems and packaging systems".

U.S. Food and Drug Administration. (2021). "Guidance for Industry: Container Closure Systems for Packaging Human Drugs and Biologics". Center for Drug Evaluation and Research.

Submit the form now to get a unique quote!

ZHEJIANG HAIZHONG MACHINERY CO., LTD.

Popular Blogs

-

Successful caseProducts and services

Successful caseProducts and servicesHow to Train Employees to Operate a Bottle Packing Machine Effectively?

-

Successful caseIndustry insights

Successful caseIndustry insightsThe Blister Packaging Process: A Complete Step-by-Step Guide

-

Successful caseComparative analysisIndustry insights

Successful caseComparative analysisIndustry insightsWhat Type of PVC Is Best for Blister Packing Machines?